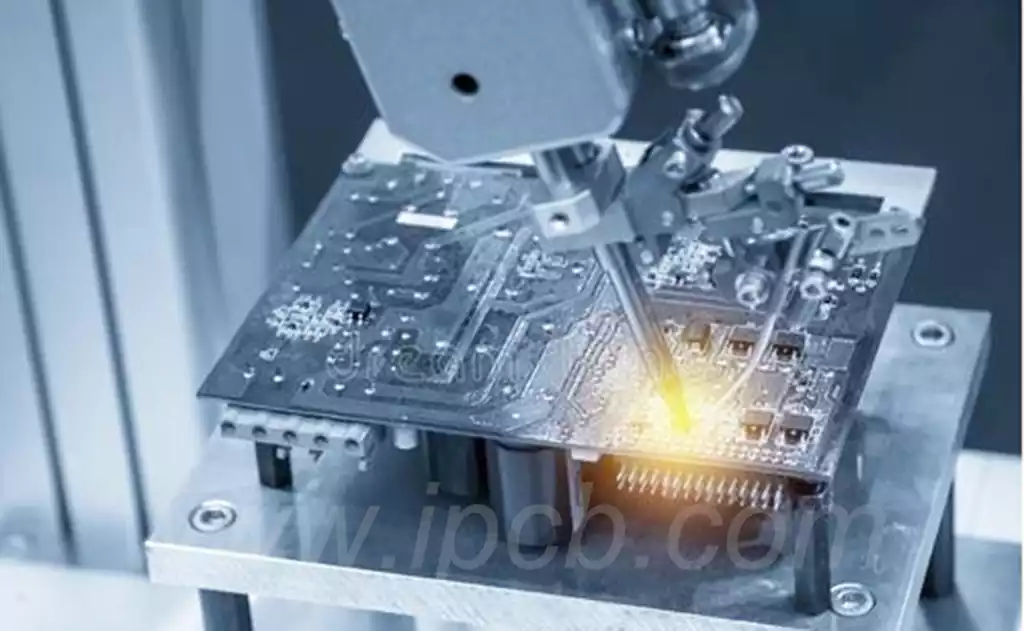

The annealing semiconductor process

What is annealing in semiconductor?Annealing semiconductor is a process that changes the electrical properties of a semiconductor material by heating it.During the annealing process, the material is heated to a high enough temperature to change its internal structure, which in turn changes the conductivity of the semiconductor. The principle of the annealing semiconductor process is […]