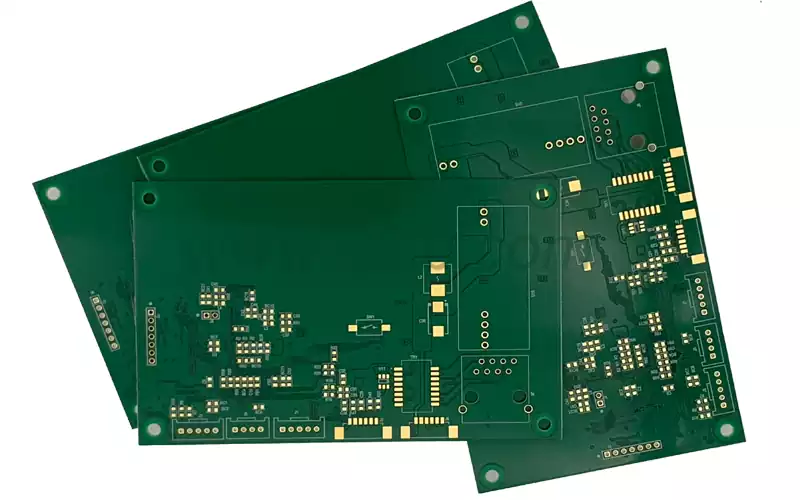

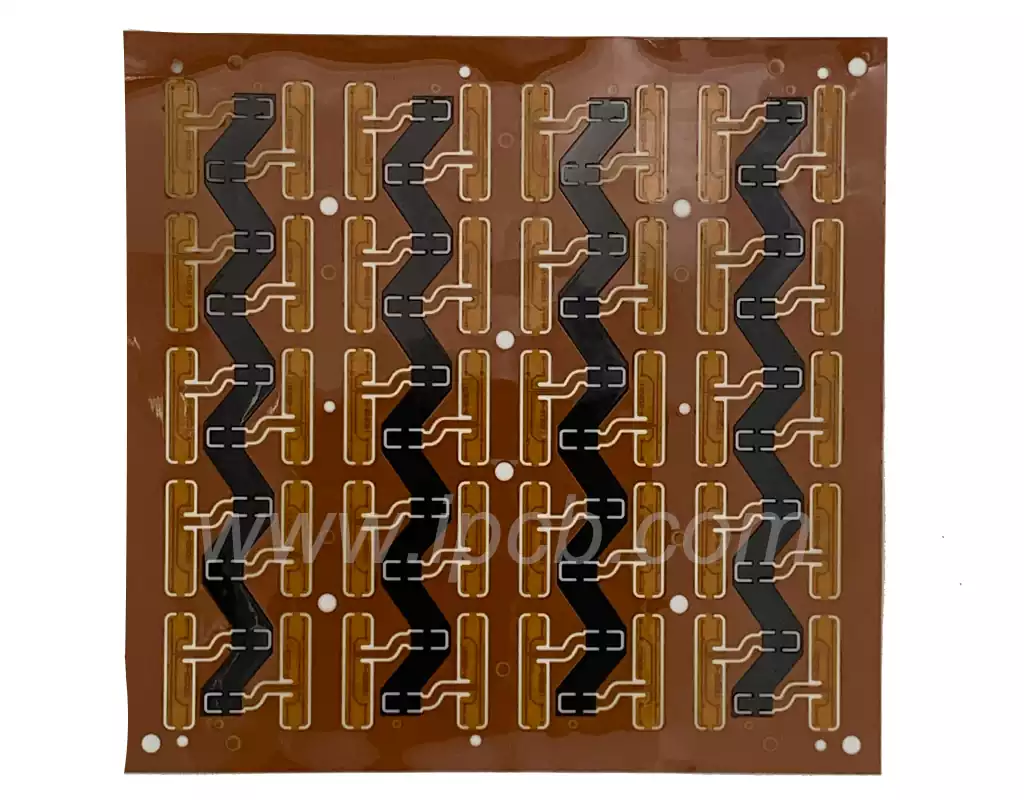

Bendable Circuit Board, or Flex PCB, is a type of circuit board that is manufactured using a flexible substrate. Its best feature is that it can be flexibly bent without affecting its performance or conductivity. Compared to traditional rigid circuit boards, flexible circuit boards have better adaptability and applicability.

FPC is the United States in the 1970s for the development of space rocket technology development technology, is made of polyester film (PET) or polyimide (PI) as a substrate with a high degree of reliability, excellent flexural printed circuits, through the bending of the thin and lightweight plastic sheet, embedded in the circuit design, so that in the narrow and limited space to stack a large number of precision components, thus forming a curved pcb.

In fact, FPC not only can be flexed, but also connected to the three-dimensional line structure of the important design method, this structure with other electronic product design, can widely support a variety of different applications, for PCB, unless the way to make the line to the mold three-dimensional form, or else the general state of the circuit board is flat.

Therefore, to make full use of the three-dimensional space, FPC is one of the good programs. PCB is currently a common space extension program, is the use of slots plus interface cards, but FPC to the adapter design can be completed with a similar structure, and the direction of the adjustment is also more flexible, the use of a piece of connecting FPC, you can connect the two pieces of PCB to form a set of parallel line system, but also can be folded into any angle to adapt to the appearance of different products.

The basic structure of FPC

Ordinary single-sided board: single-sided copper foil substrate + cover film.

Dummy double-sided PCB: Cover film + pure copper foil + cover film. Some suppliers will not do this kind of structure and avoid it.

Single panel with press-fit connection: single-sided copper-clad substrate + covering film + reinforcement plate.

Skeletonized panel: Covering film + Pure copper foil + Covering film.

Double-sided boards: Cover film + Double-sided copper foil substrate + Cover film.

Curved circuit board features:

1.Bendability

Bendable circuit board can be bent, folded, curled, rotated, etc., so they have a unique superiority in some specific scenarios. For example, devices with small size or large curved surface curvature can use this type of circuit board to solve the problems that conventional circuit boards cannot accommodate.

- Thinness

In the use of flexible substrates for manufacturing, curved pcb can achieve a thinner image, which is a considerable advantage for equipment to solve the volume problem.

3.Reliability

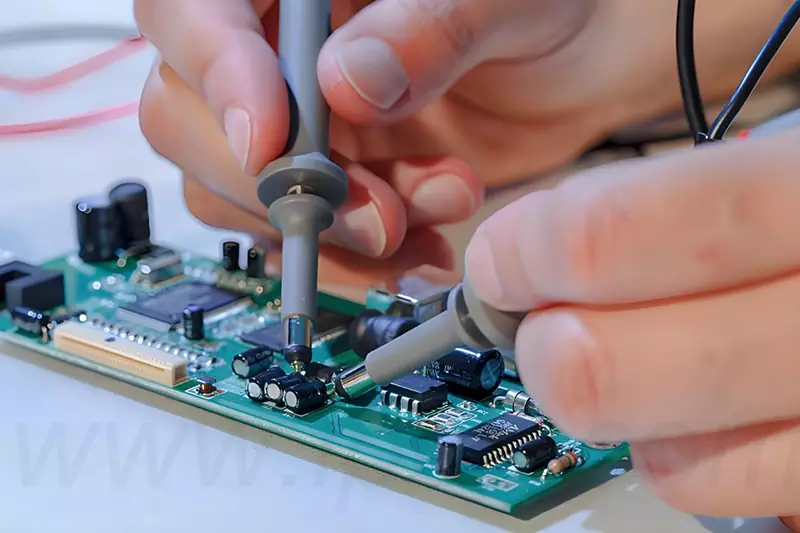

The reliability of bendable circuit boards is superior compared to conventional rigid circuit boards. This is due to the fact that during the manufacturing process, both the insulating material and the conductor portion can be better articulated and fitted to each other, resulting in better performance and conductivity.

FPC has a wide range of applications, including but not limited to the following areas:

- Consumer electronics

FPC products have important applications in the field of consumer electronics. For example, in electronic devices such as smartphones, tablets and laptops, as well as wearable devices such as watches and bracelets, FPC products are used as flexible connection lines to connect various components and transmit signals.The flexibility and bendability of FPC products enable them to adapt to the design needs of devices of different shapes and sizes, providing a better user experience. - Automotive Electronics

With the rapid development of automotive electronics, FPC products in the field of automotive electronics is more and more widely used, FPC products can be used in automotive instrument panels, center panels, seat adjusters and in-vehicle entertainment systems, new energy battery wiring and so on, to achieve the signal transmission, power supply and data processing functions, etc. FPC products have a smaller size and better temperature resistance, to meet the special needs of the automotive electronics. FPC products have a smaller size and better temperature resistance,which can meet the special needs of automotive electronic equipment.

3.Industrial control

FPC circuit boards have a long life, aging resistance, and can provide high-performance industrial control systems, often used in industrial robots, sensors, controllers and so on.

4.Medical equipment

FPC flexible circuit boards are also widely used in medical equipment, such as medical instruments and some life-monitoring equipment, commonly found in endoscopes, facial instruments, MRI helmets, foot massagers and so on.

5.Smart Home

In the field of smart home, FPC flexible circuit boards are mainly used in temperature measurement, smart switches, infrared remote control and sensors and other fields. Among them, the smart switch made of FPC circuit board can realize the remote control switch and timing function, and can monitor and control the status of the switch through the APP on the cell phone. For example, sensor faucet, intelligent toilet, thermostatic insulation cup, remote control module and so on.

Bendable circuit board has the advantages of high density, high reliability, high flexibility, thin and short, good solderability, good bending, etc. FPC has a wide range of applications, covering almost all areas that require flexible circuit connections.