Key Factors Affecting PCBA Processing Costs and Quotation Efficiency

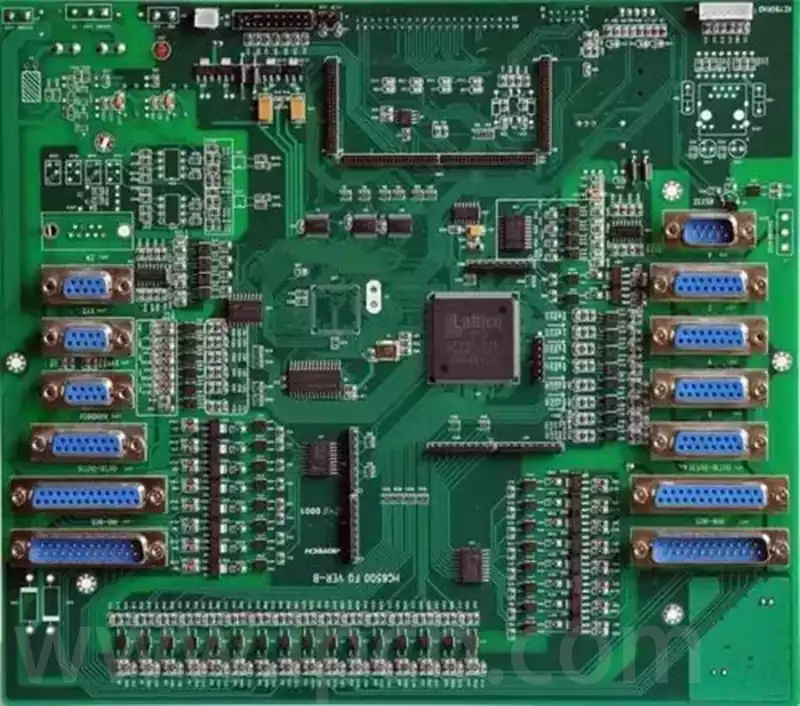

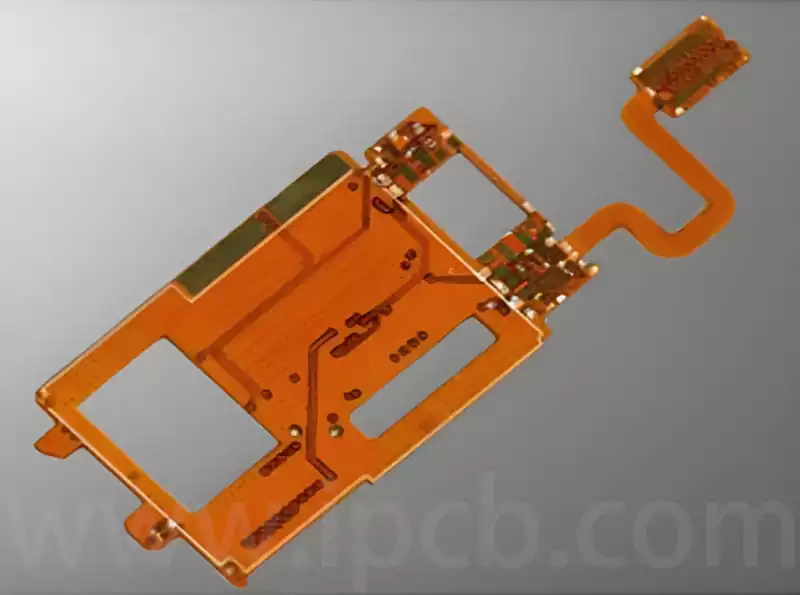

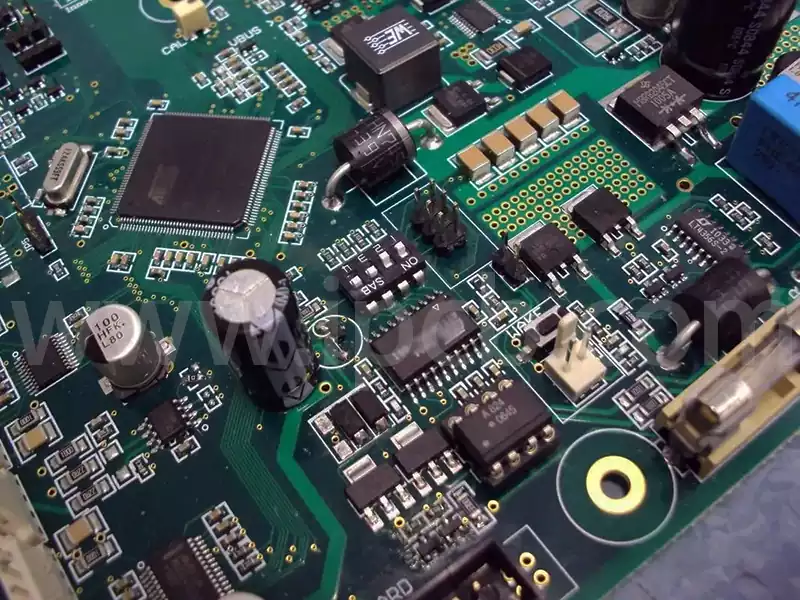

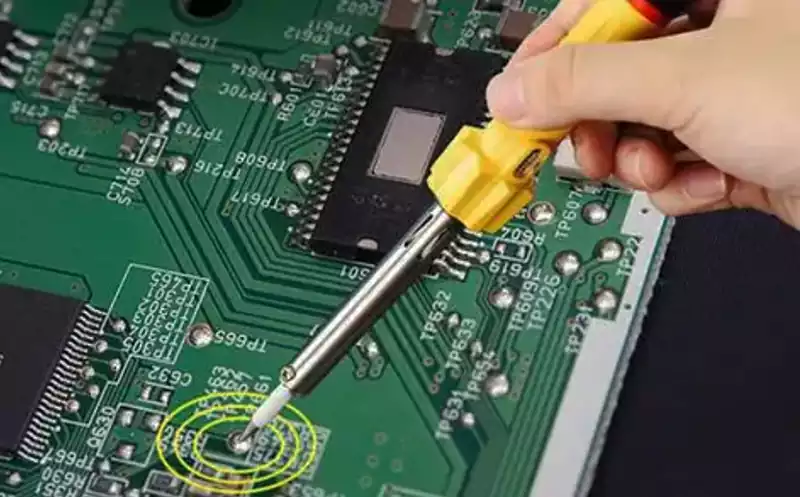

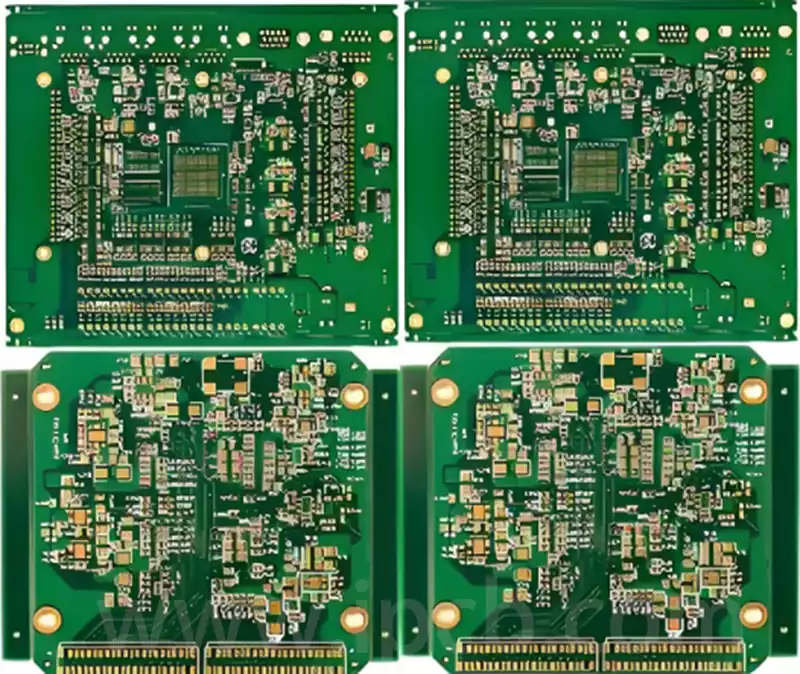

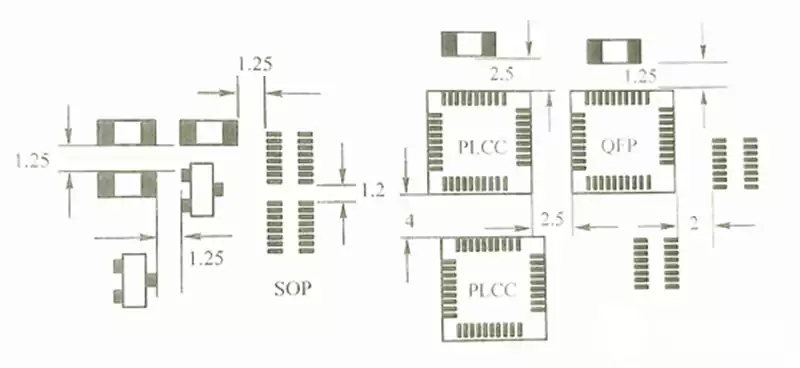

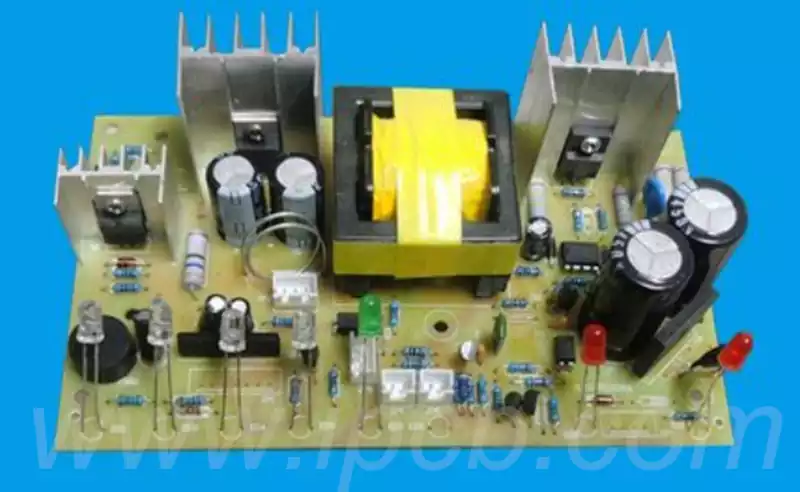

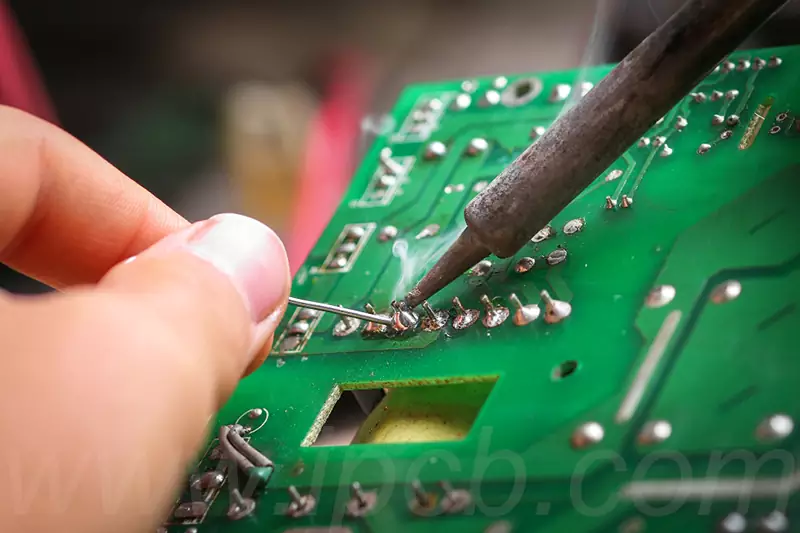

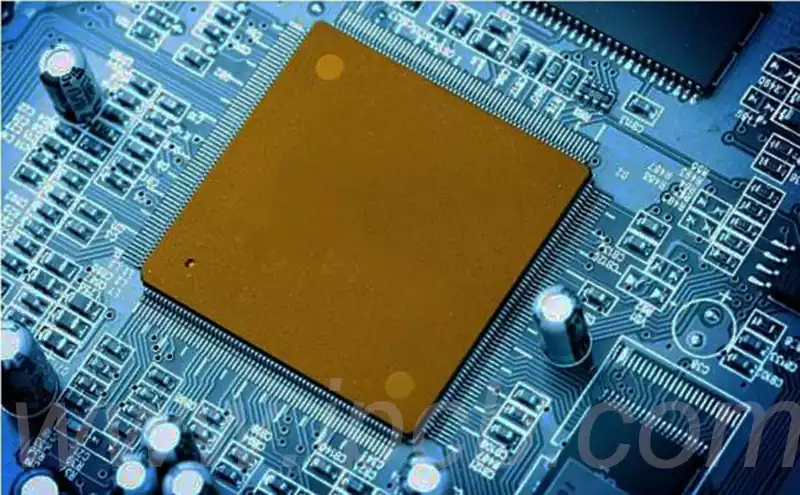

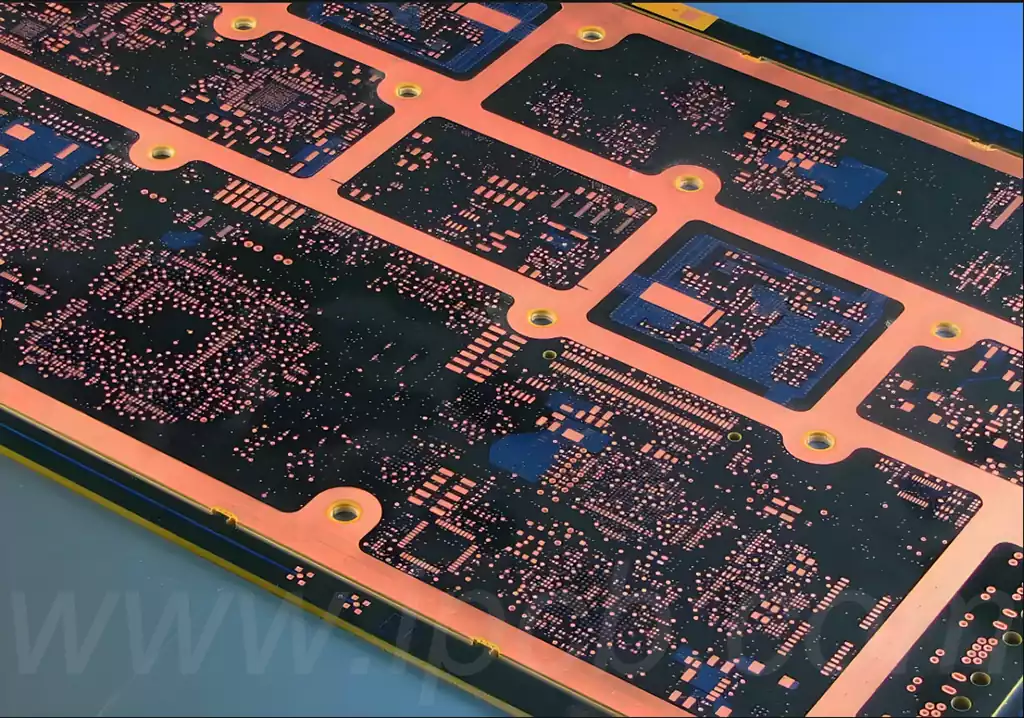

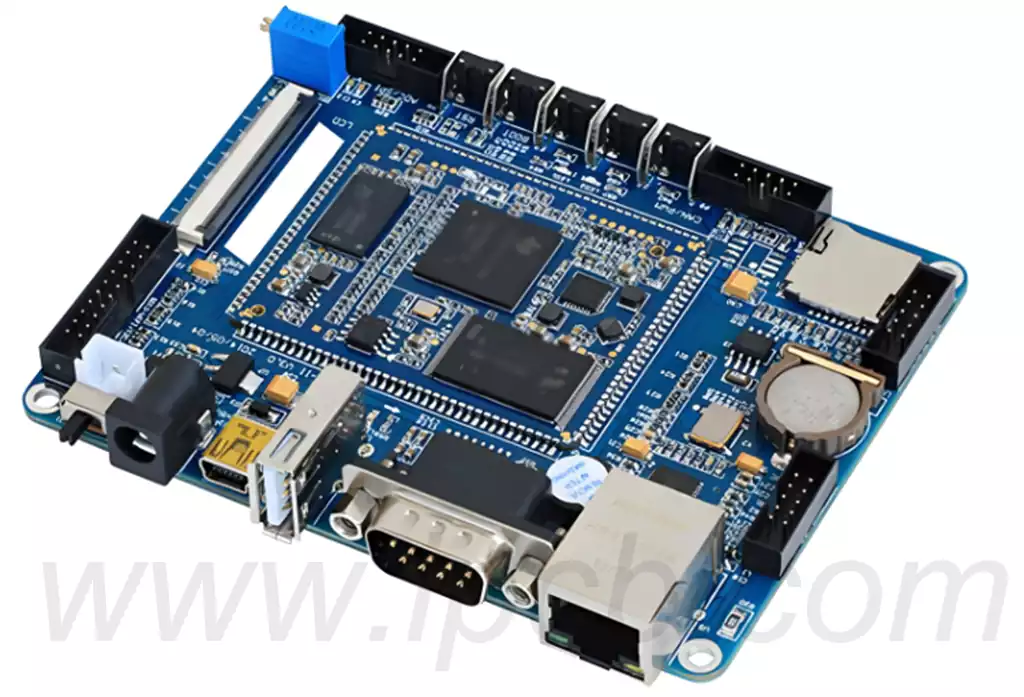

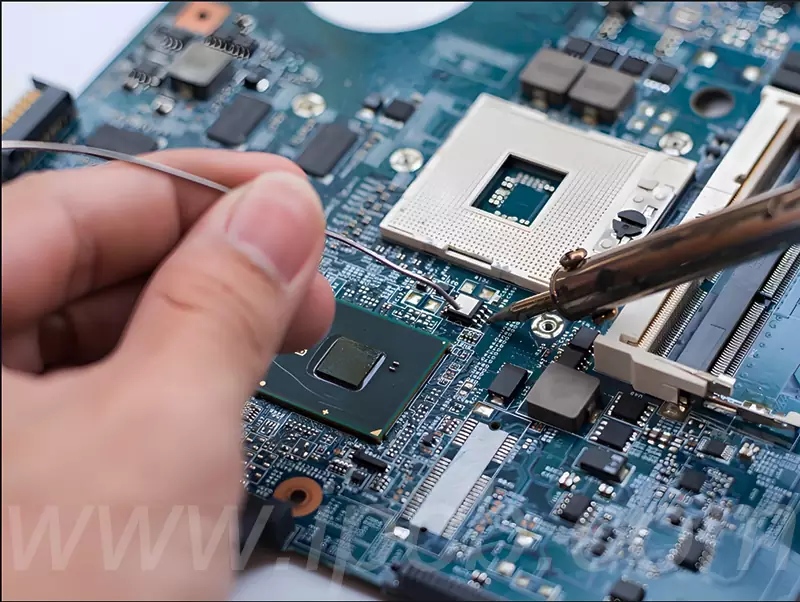

PCBA processing costs encompass multiple stages including PCB manufacturing, component procurement, SMT placement, DIP insertion, and testing/validation. Quotation efficiency is influenced by factors such as design file completeness, supply chain alignment, process complexity, batch size, and testing requirements. This article systematically outlines the cost components of PCBA and analyses key factors affecting quotation timeliness. PCBA […]