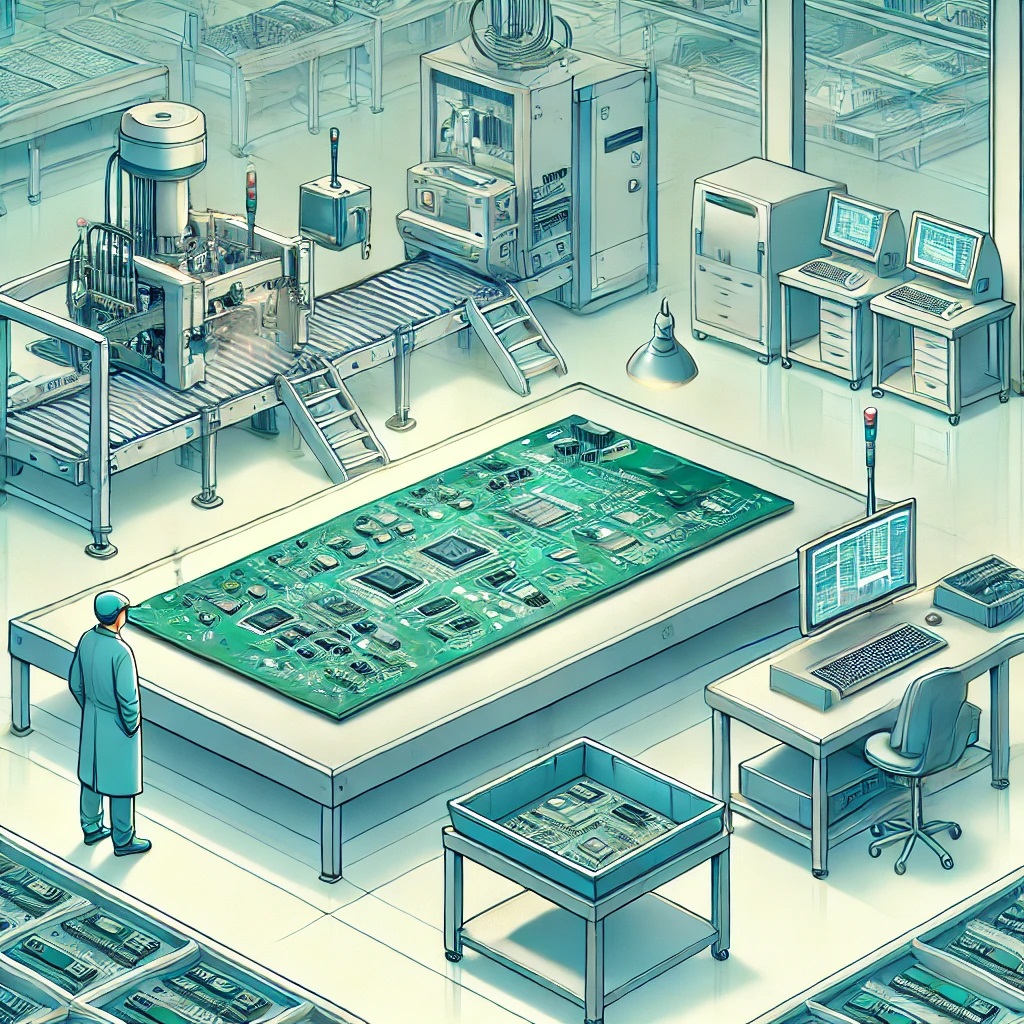

5 Sections for a Better Understanding of PCBA Contract Manufacturing

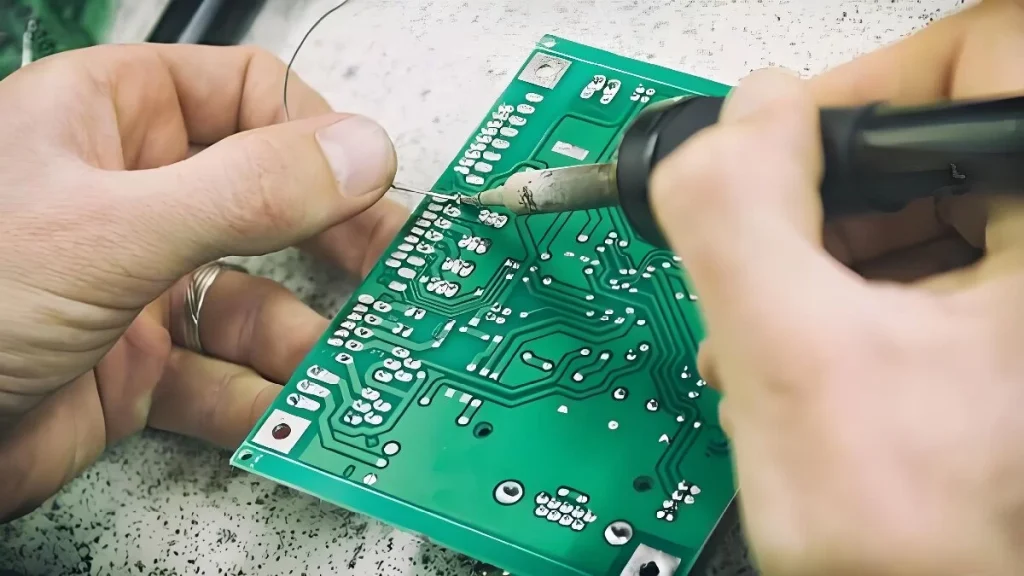

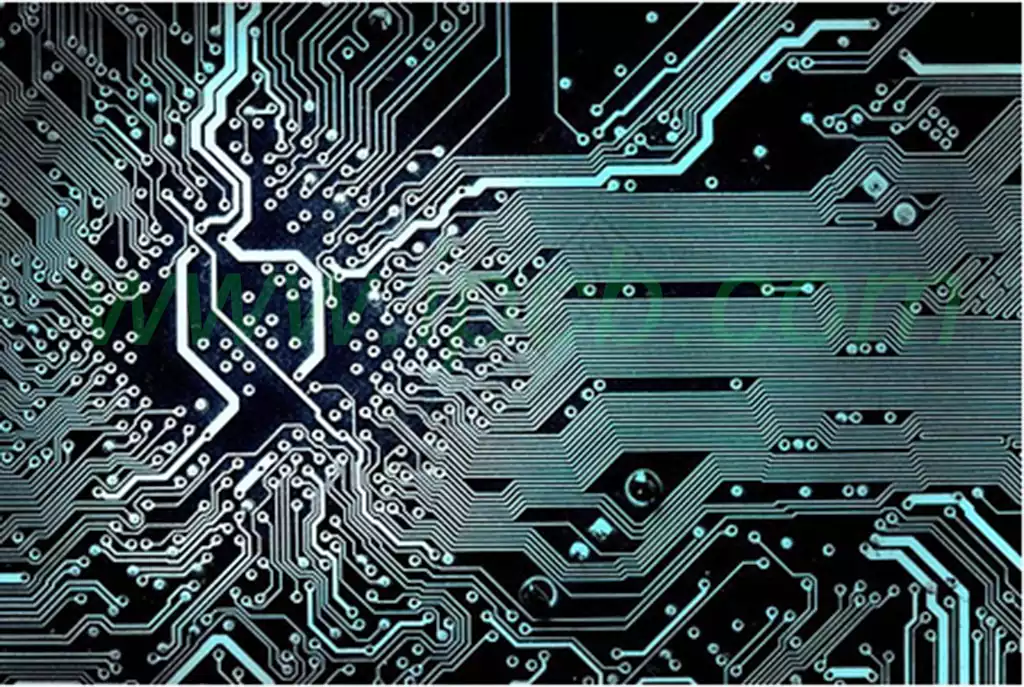

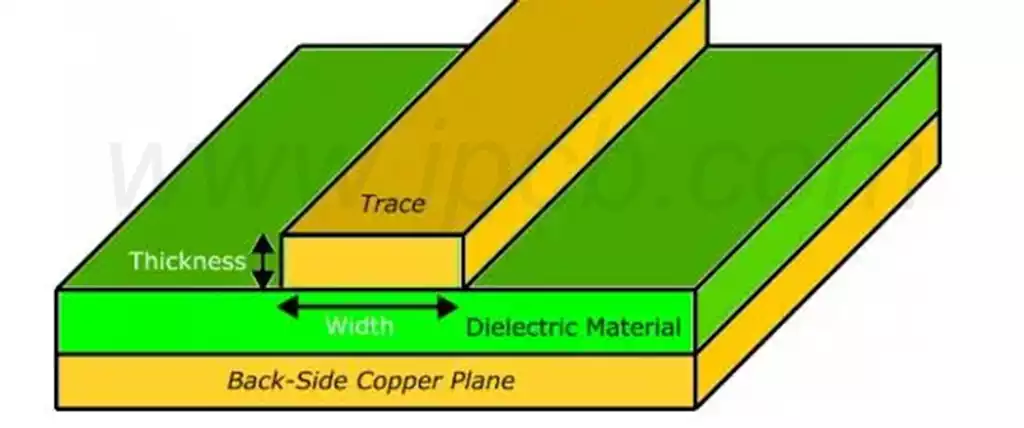

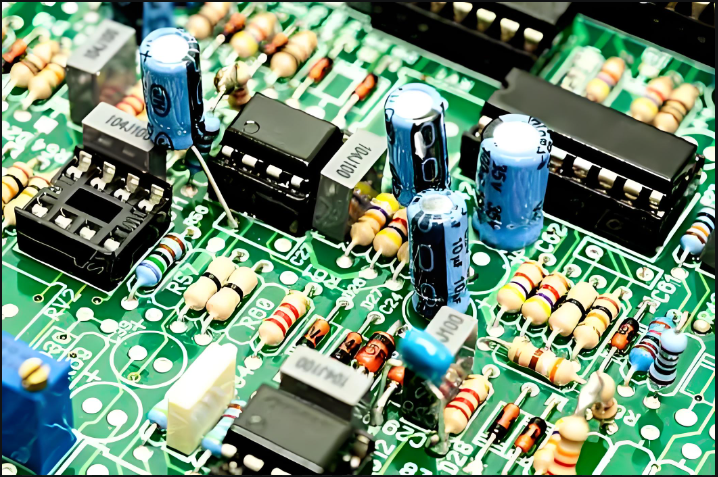

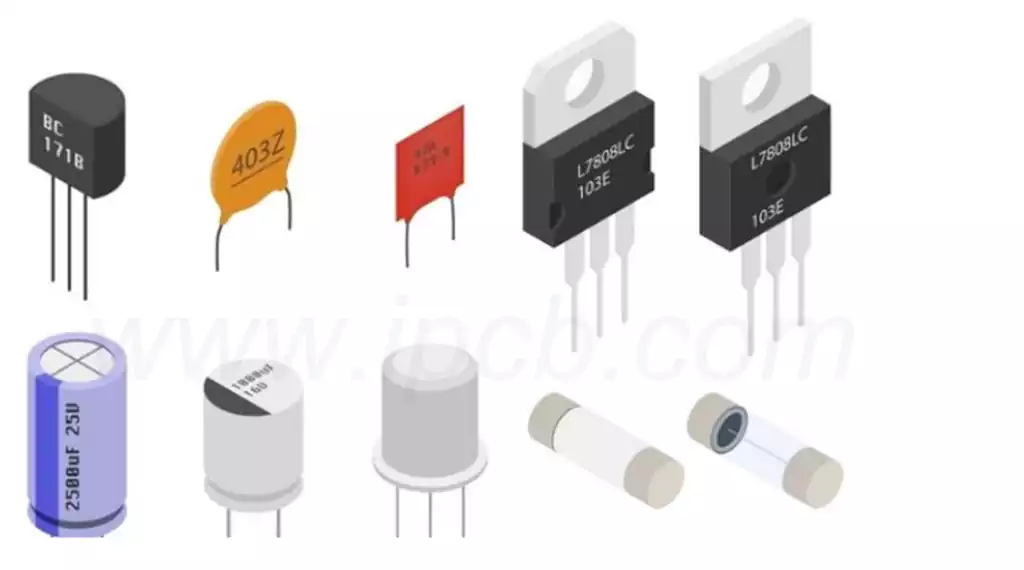

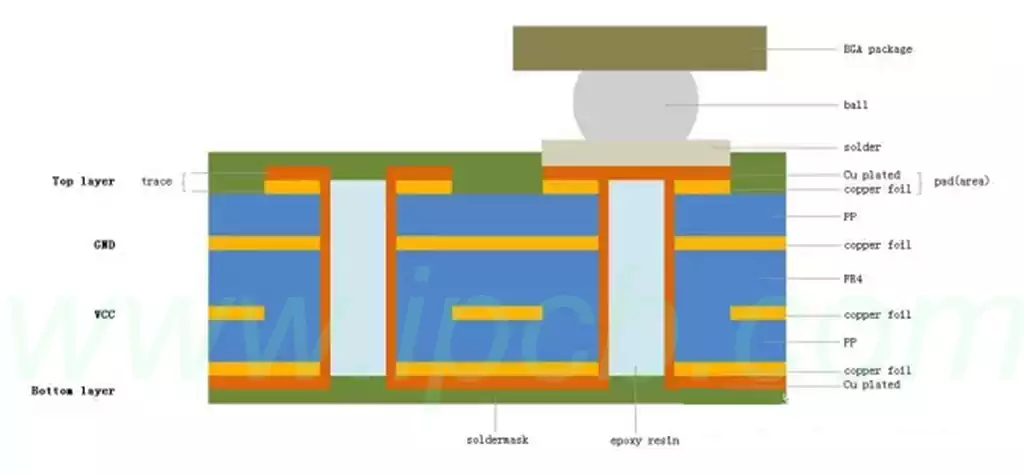

PCBA contract manufacturing is a critical service in the electronics industry. It involves outsourcing the assembly of electronic components onto a printed circuit board (PCB) to specialized manufacturers. This process is essential for companies that need high-quality assemblies but may lack the necessary resources, expertise, or equipment to produce them in-house. PCBA contract manufacturing enables […]