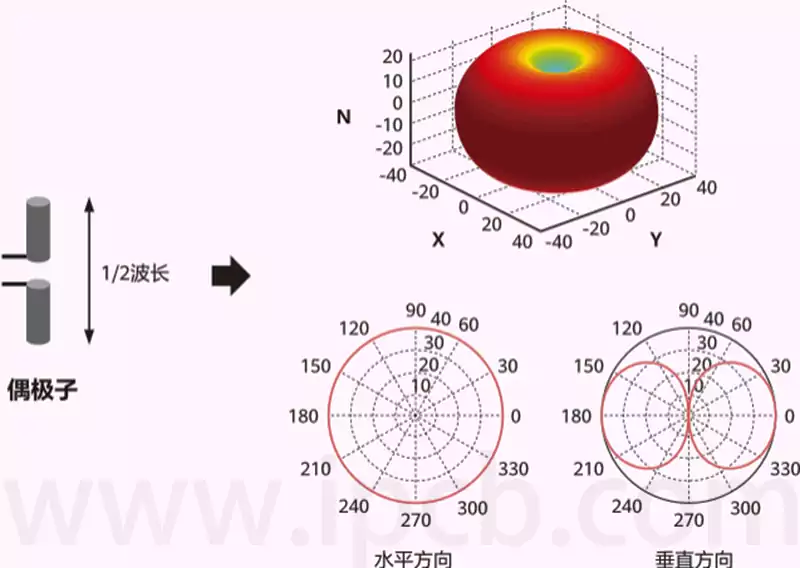

Characteristics and applications of dipole antenna

What is a dipole antenna? A dipole antenna is a basic antenna used to broadcast radio frequencies. A dipole antenna is named after the two conductors of equal length that extend from either side of the antenna. A dipole is an omnidirectional antenna, which means that it broadcasts frequencies in all directions at the same […]