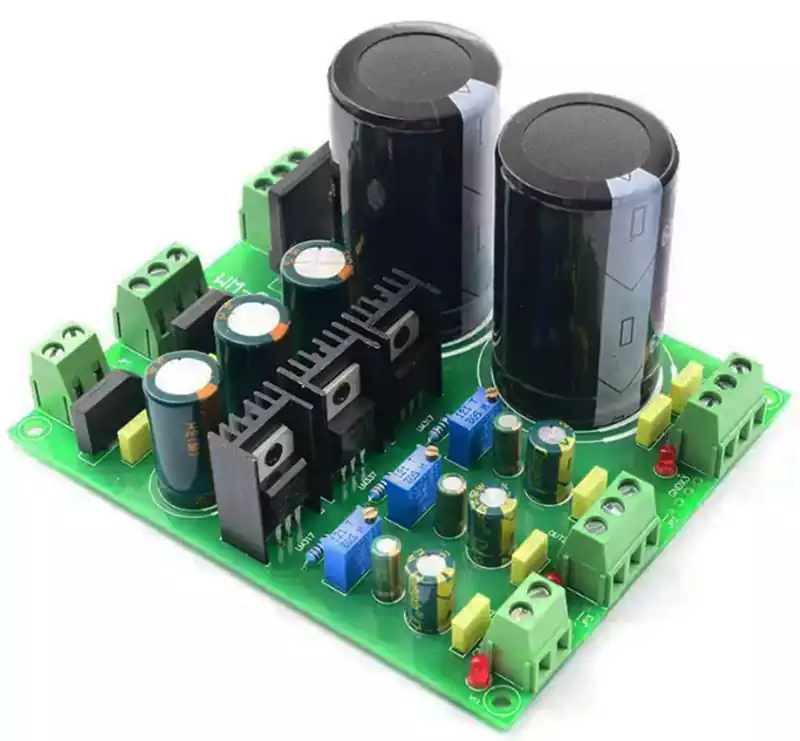

ATE (Automatic Test Equipment) testing is an automated test method for comprehensive inspection and evaluation of chips. It carries out comprehensive testing and evaluation of chips through specialized test equipment.ATE test equipment simulates various working environments and conditions by sending specific test signals to the chip to detect the chip’s function, performance, electrical characteristics and defects in the manufacturing process. The purpose of such testing is to ensure the quality and reliability of the chip, as well as performance verification before product delivery, thus improving productivity and product quality.

ATE testing includes structural testing (such as coverage testing), functional and performance testing, etc. It can detect the various performance indicators of the chip, such as voltage, current, frequency, etc., to ensure that the chip can operate stably and reliably in various operating environments, which is a key link to ensure the quality of the chip and an indispensable part of the production of electronic products.

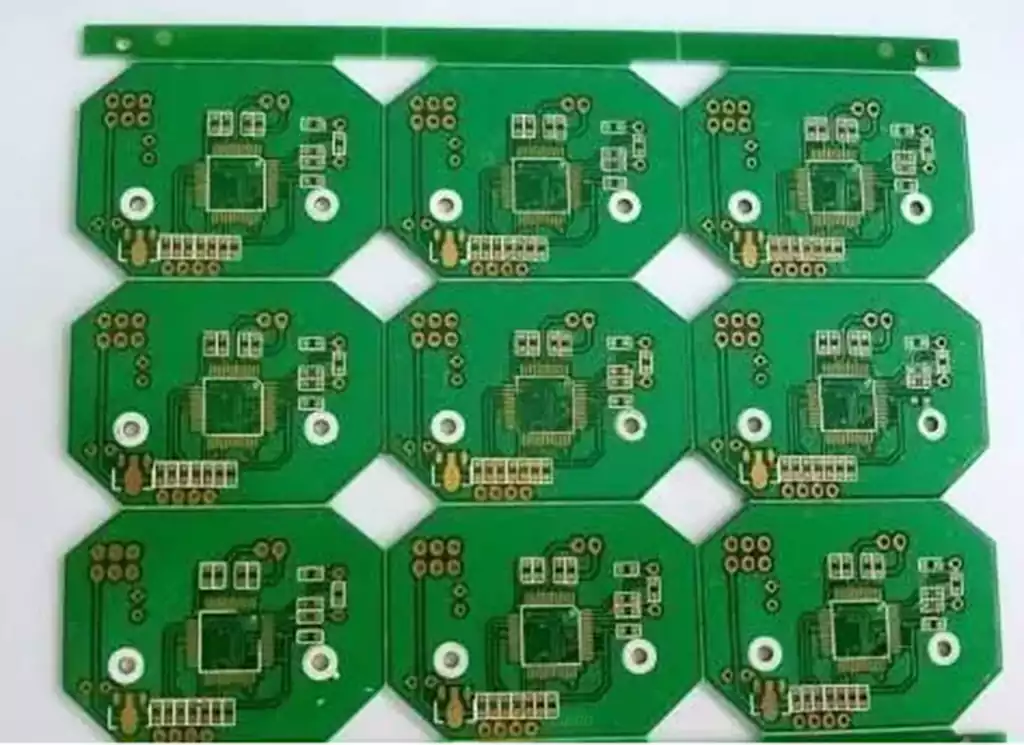

Structural testing, such as coverage testing, focuses on the internal structure and connection of the chip. It utilizes specialized test equipment and methods to comprehensively detect manufacturing defects, placement and connection of parts of the chip pcb. This type of testing helps to identify problems that may exist in the manufacturing process of the chip and ensures the structural integrity of the chip.

Functional testing focuses on verifying whether the various functions of the chip work properly according to the design requirements. Test equipment simulates a variety of actual operating environments and conditions, sending various signals to the chip to check whether it can respond correctly and produce the expected output. This step is critical because it ensures that the chip will meet the requirements of the actual application.

Performance testing measures and evaluates the chip’s speed, power consumption, throughput and other key parameters. By comparing with the actual requirements, ATE test ensures that the chip meets or exceeds the design requirements in terms of performance.

The importance of ATE testing is mainly reflected in the following aspects.

Improve chip performance: It can comprehensively evaluate and optimize various performance indicators of the chip, such as computing speed and power consumption. This means that through ATE testing, you can ensure that the chip in the actual application of excellent performance to meet the changing market demand.

Ensure Functional Integrity: It is possible to perform automated testing of the various functional modules of the chip board to determine whether they are functioning properly. This helps to ensure that the chip performs correctly under various operating conditions, reducing the failure rate and thus improving the overall reliability of the product.

Enhance productivity: ATE test equipment can automate the test process, significantly improving test efficiency and accuracy. This means that manufacturers can complete a large number of test jobs in a shorter period of time, thus saving human resources and time costs and improving productivity.

Guarantee product quality: The ability to provide highly accurate and repeatable test results eliminates human-operated inconsistencies and errors, thus improving test reliability. This is critical to ensure product consistency and stability, especially in high-volume production.

ATE testing is the key link to ensure the quality and performance of electronic products. It is like the “gatekeeper” of electronic products, ensuring that every chip is in the best condition for production and use.