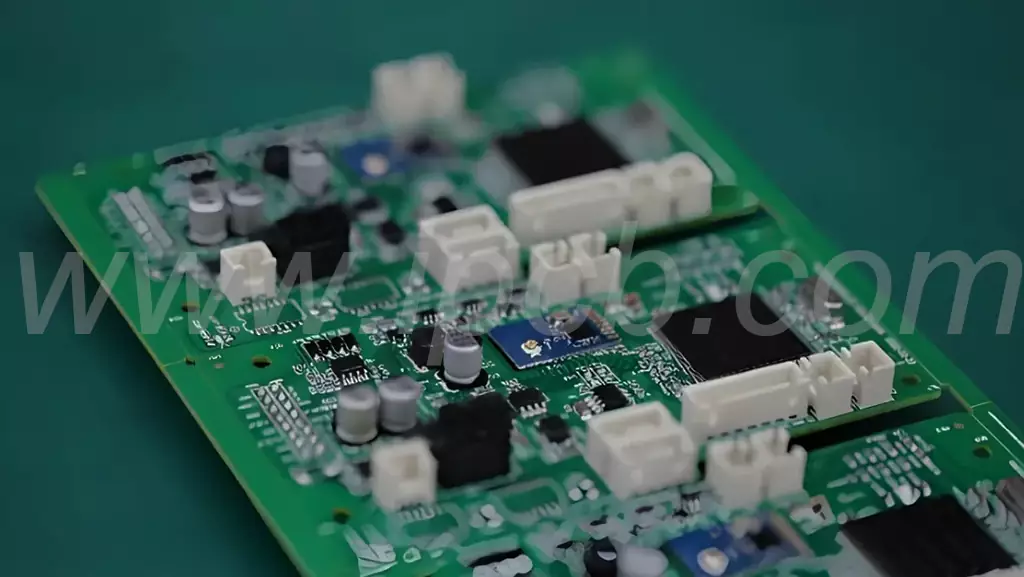

Chip on board ic refers to a system formed by pasting a chip directly onto a circuit board, usually in an unpackaged or simplified package.This technology allows electronic components to be more tightly connected to the circuit board, which significantly improves the efficiency of space utilization and the overall performance of the system.

The use of chip on board ic technology reduces the amount of space occupied by the circuit board, while lowering production costs. By reducing the materials and processes required for traditional packaging, on-board chips typically offer higher manufacturing efficiencies and better electrical performance.

Advantages of chip on board ic

- High Integration

Chip on board ic allows multiple chips and components to be mounted directly on the same board, significantly reducing the overall board size. Due to this high level of integration, device designs can be more compact, especially suitable for space-constrained application scenarios, such as mobile devices and portable electronics. - Reduced power consumption

Since the chip on board ic does not use lead bonding, it reduces the complexity of the electrical connection, thus reducing power loss. This feature gives on-board chips a significant advantage in applications that require high efficiency and long life. For example, LED lighting products using on-board chips can effectively manage heat and improve overall operating efficiency. - Cost Effectiveness

Chip on board ic technology reduces the materials and processes required for traditional packaging, thereby lowering production costs. By reducing reliance on individual packages, manufacturers can realize more high-performance IC products at lower costs. - Improved Thermal Management

Mounting the chip directly on the circuit board enhances the thermal conduction performance and enables effective heat transfer into the PCB, reducing heat emissions. This improved thermal management is critical to maintaining device stability and reliability,especially in high power applications. - Improved Performance

On-board chips provide better electrical performance due to the reduction of possible instabilities in the packaging process. At the same time, the direct connection reduces the delay in signal transmission, making the device perform better when processing data. Therefore, on-board chips are widely used in products that require high performance and fast response. - Cross-field application capability

On-board chips not only perform well in consumer electronics, but also show great potential for application in many fields such as medical, automotive and industrial control. With the increasing demand for miniaturized and high-efficiency products, their applications in different fields will continue to expand.

Performance differences between chip on board ic and traditional packaged chips

- Integration

Chip on board ic technology allows multiple chips and components to be mounted directly on the same circuit board, resulting in a higher level of integration. Compared with traditional packaging, this technology results in more compact device designs, which are especially suitable for space-constrained application scenarios, such as mobile devices and portable electronics. - Power consumption

It also performs well in terms of power consumption. By optimizing the layout and connection of the chips, it is usually possible to achieve lower power consumption than traditional packaging. This makes it particularly suitable for devices that require high energy efficiency. - Thermal Management

Another advantage lies in its thermal management capability. Since the chip is directly integrated into the circuit board, it is able to conduct heat more efficiently into the PCB, which improves heat dispersion. This is less efficient compared to traditional packages where heat must be transferred through multiple layers of material. This improvement can contribute to the stability and reliability of the device, especially in high power applications. - Cost Effectiveness

It also offers significant advantages from a cost perspective. Its manufacturing process reduces the reliance on separate packaging materials,lowering production costs and material usage.This makes on-board chips a promising economic solution, especially for products with high integration requirements such as sensors, power integrated circuits and RF modules. - Electrical Performance

In terms of electrical performance, on-board chips significantly reduce the complexity of electrical connections by being affixed directly to the circuit board. This feature reduces the delay in signal transmission, thus providing better electrical performance. In contrast, conventional packages connect the chip through lead bonding, etc., which can lead to signal loss and delay.

Chip on Board IC technology is widely used in a number of applications due to its high level of integration and superior electrical performance:.

- Consumer Electronics

Chip-on-board (COB) is widely used in consumer electronics products such as smartphones, tablets and other portable electronic devices. These products usually require compact size and high performance, and on-board chips can effectively meet these needs by directly integrating the chip into the circuit board to achieve better space utilization and electrical performance. - Lighting and LED Applications

In the lighting industry, chip on board ic technology has also been widely used, especially in LED lighting products. Due to its miniaturization, low power consumption and high-density features, on-board chips can provide superior thermal solutions and electrical connections for LED lamps and lanterns, thus improving the overall performance and reliability of the lamps and lanterns.

3.Communication equipment

Communication equipment is one of chip on board ic important application areas. They are widely used in RF modules, microwave components and other core communication parts to ensure high-speed and reliable data transmission. The realization of this technology has helped to enhance the performance of communication equipment, making it perform better in signal transmission and processing.

- Industrial control and medical equipment

Chip on board ic technology plays an equally important role in industrial control and medical equipment. In these areas, equipment often requires a high level of accuracy and reliability, on-board chips can improve the integration of components, reduce the use of space, and enhance the overall functionality of the device. For example, on-board chips are often used in medical instruments to ensure efficient performance and accurate data acquisition.

Key factors to consider when designing an on-board chip:

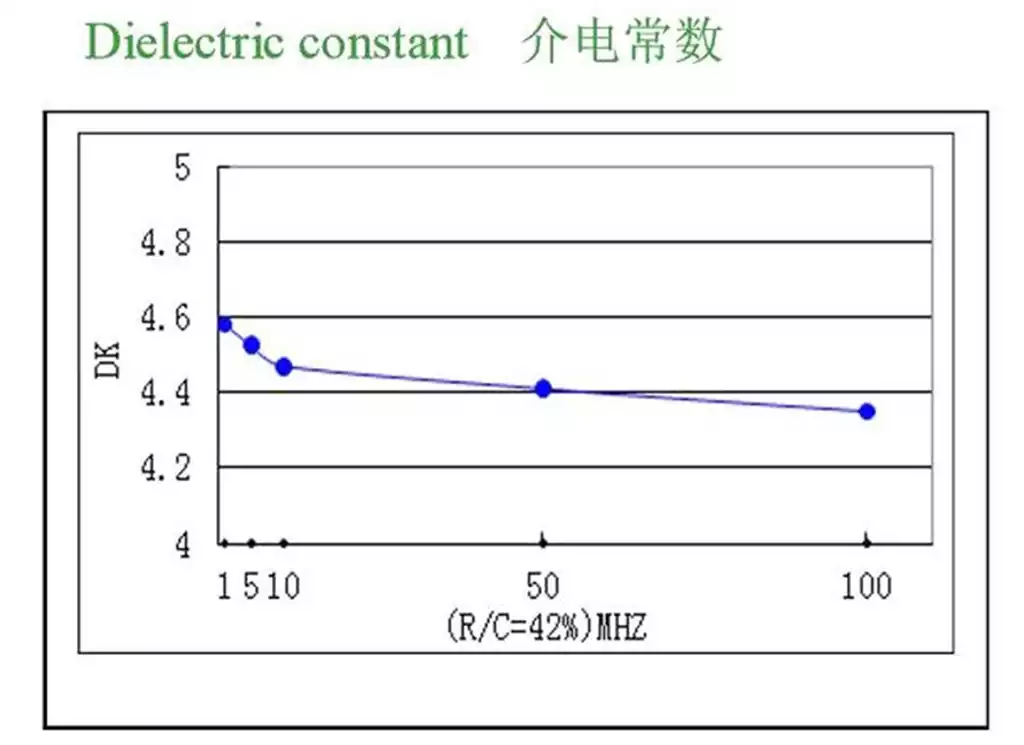

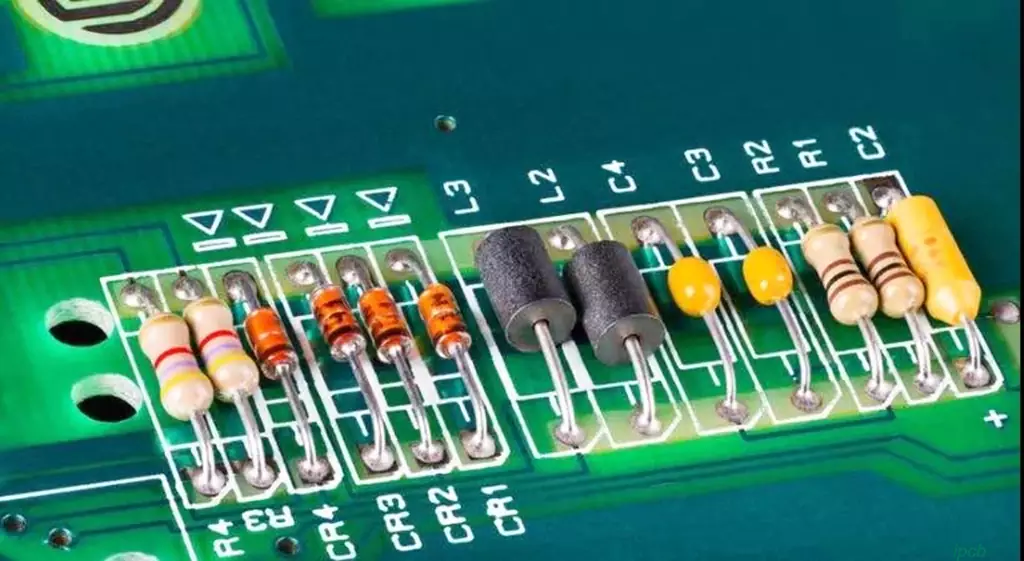

- Material selection

The choice of material is critical to the performance of the on-board chip. The selection of conductive materials involves properties such as electrical and thermal conductivity and mechanical strength, which affect current flow and heat dissipation. Insulating materials need to have excellent insulation resistance and humidity resistance to prevent short circuits and performance degradation. The chemical resistance of the materials needs to be carefully evaluated during design to ensure long-term use in a variety of environments. - Thermal Management

Thermal management is a key factor in ensuring the performance and reliability of on-board chips.Designs need to consider the use of materials with high thermal conductivity,as well as innovative heat dissipation techniques (such as thermal interface materials TIM,heat sinks, and liquid cooling systems) to effectively dissipate heat.Thermal analysis and simulation tools should also be incorporated into the design process to predict heat distribution and optimize component layout. - Electrical Performance

Electrical performance is primarily concerned with signal integrity and power management.The design should ensure a stable and clean power supply to meet the challenges of rapidly changing loads. Signal distortion,reflection and noise should be minimized to ensure signal quality and timing consistency. This is especially important for high-speed interconnects. - Package Design Standards

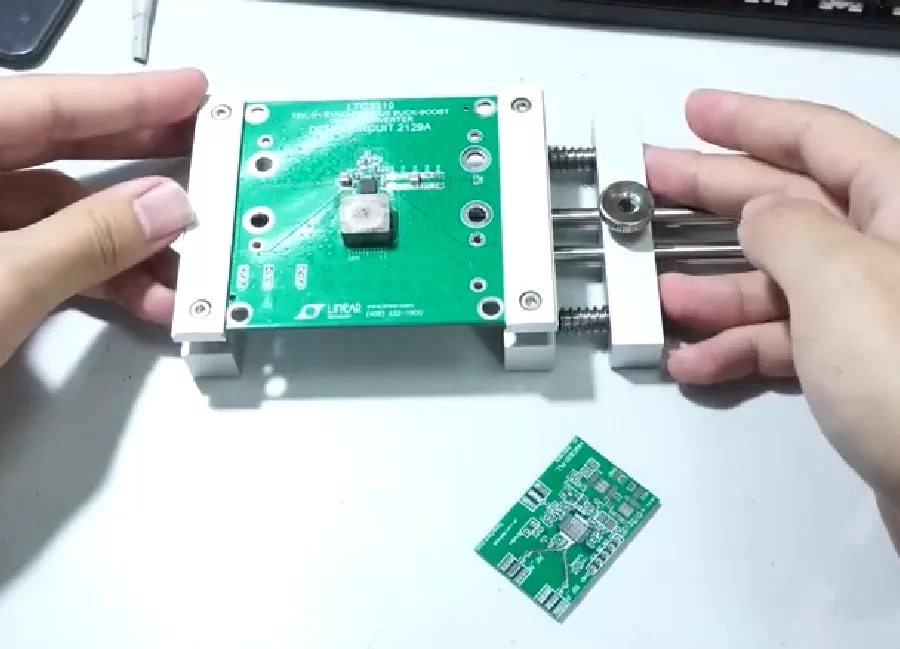

Adherence to package design standards and specifications is a necessary step to ensure compatibility and reliability. These standards include line width and spacing, pad design, power and ground layout, component layout and so on. Perfect design specifications can reduce design errors and improve PCB manufacturing quality and performance. - Manufacturing process

Design of the manufacturing process also has a direct impact on the quality of the final product.Need to consider the SMD technology (SMT) and soldering methods to ensure a good combination of chip and PCB board. Simple and effective processes can improve production efficiency and reduce costs, while ensuring product quality.

Chip on board ic technology is rapidly changing the design and manufacture of modern electronic devices with its high integration, low power consumption and excellent electrical performance. As intelligent and IoT technologies continue to advance, the potential of on-board chips to improve device performance, reduce size, and lower costs will become increasingly significant. Key factors in the design process, such as quality material selection, effective thermal management, and stable electrical performance, will have a profound impact on overall product quality and market competitiveness. Looking ahead, as industry needs evolve, on-board chip technology will continue to drive innovation and development in all areas, and is an important foundation for realizing more efficient and smarter electronics.