In electronic manufacturing, PCB board quality forms the cornerstone for ensuring device performance and reliability. However, within complex production processes, multiple factors may induce various defects in PCBA, thereby compromising the final product’s functionality. This article delves into four prevalent defect categories in PCBA manufacturing: delamination, plated-through-hole copper fractures, pcb board warping and buckling, and pad detachment with oxidation. Corresponding prevention and resolution strategies are proposed.

Common PCB Board Defects and Countermeasures

- Delamination Issues

Delamination refers to the separation or bubbling occurring within the substrate or between layers during PCBA processing or usage. This constitutes a severe quality defect potentially leading to complete circuit board failure.

Causes of Failure:

Material Defects: The resin within the PCB substrate itself may exhibit internal cracks.

Moisture Absorption: PCB substrates are hygroscopic. If PCB boards are exposed to excessive humidity during storage or production, or if packaging is compromised, moisture absorption may occur. When heated, this moisture expands into vapour, causing delamination or blistering.

Insufficient or uneven resin flow: Layers with low copper content may exhibit resin deficiency in certain areas due to inadequate resin content in the PP material. If buried vias in inner layers are not pre-filled, insufficient PP resin filling during lamination can also cause resin deficiency. Additionally, resin migration from the board edges during lamination may result in insufficient resin at the edges, triggering delamination.

Thermal stress: Inappropriate thermal processing, such as excessive preheating or soldering times, may cause board delamination.

Resolution strategies:

Material selection: Utilise PCB substrates with high-temperature resistance and low moisture absorption.

Baking and dehumidification: Thoroughly bake PCB board prior to soldering to remove internal moisture.

Optimise Laminating Process:

Select PP materials with sufficient resin content based on residual copper rate and resin filling requirements.

For blind/buried vias, pre-fill with resin plugs if PP resin volume is insufficient.

Set laminating parameters appropriately to prevent resin flow deficiency.

Control Soldering Profile:

Set soldering temperature profiles rationally, avoiding excessively high temperatures and prolonged soldering times to minimise board thermal exposure.

- Copper Fracture in Plated-Through Holes

Copper fracture in PCB plated-through holes refers to the breakage of copper foil within conductive vias on circuit boards, resulting in electrical connection failure.

Causes of Failure:

Thermal Shock: High temperatures during SMT and wave soldering in PCB manufacturing, coupled with significant ambient temperature fluctuations during prolonged use, may cause copper fracture in vias. The probability of fracture increases following thermal cycling tests.

Material Properties: The Z-axis coefficient of thermal expansion (CTE) of PCB substrates is significantly higher than that of the via copper. During abrupt temperature shifts, stress concentration points are prone to snapping the via copper.

Manufacturing Processes: Poor drilling or deburring techniques, such as excessive hole wall roughness or residual burrs within the hole, create stress concentration zones that promote crack initiation and propagation. Issues in the electroless copper plating process may also compromise hole copper quality.

Design Factors: Design elements such as excessively small hole diameters, thicker board materials (excessive thickness-to-diameter ratio), narrow hole spacing, irregular hole shapes, and excessive layer counts may all increase the risk of hole copper fracture.

Mitigation Strategies:

Temperature Control: Set PCBA production temperatures appropriately based on material properties to minimise thermal shock.

Material Selection: Select PCB substrates meeting long-term service requirements, with particular attention to thermal expansion coefficients to minimise the probability of long-term copper fracture.

Process Control: Strictly manage PCB manufacturing processes. Conduct production and reliability testing on PCBs from mass-production suppliers to promptly identify and resolve manufacturing issues. Maintain unobstructed plating solution flow within vias to ensure electroplating quality.

Design optimisation: Incorporate design allowances into PCB layouts. For multilayer boards, increase via thickness and strategically position non-functional pads.

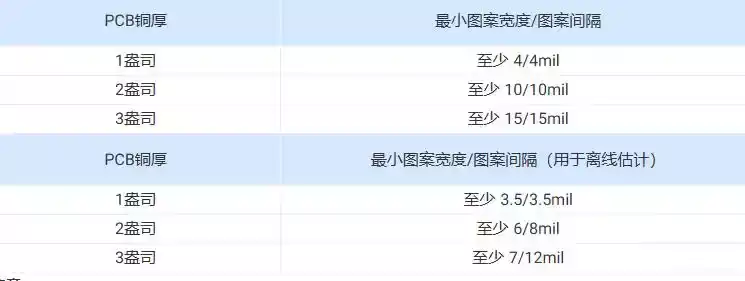

- PCB Board Warping and Bending

PCB board warping and bending refers to irregular deformation occurring during manufacturing or use, which may compromise component mounting and soldering quality, or even prevent equipment from functioning correctly.

Causes of Failure:

Material Properties: Differences in thermal expansion coefficients and mechanical properties between materials may cause warping or bending if improperly matched.

Manufacturing Process: Inappropriate soldering temperatures and durations, coupled with uneven heat distribution during soldering, may induce warping. PCB thickness variations can also contribute to bending.

Design Layout: Unreasonable circuit design, such as uneven copper residue distribution, asymmetrical layer stacking, oversized board dimensions, or improper placement of heavy components, can induce warping. Significant variations in copper foil distribution cause uneven stress during thermal expansion, resulting in deformation.

Environmental Factors:

Fluctuations in temperature and humidity during production and storage cause thermal expansion and contraction of PCB materials, resulting in board warping.

Improper Storage and Handling:

External forces causing bending or twisting during storage or handling, alongside humidity and temperature in storage environments, may compromise board flatness.

Countermeasures:

Material Selection: Select appropriate board thickness and dimensions, and choose materials of the same grade or from the same manufacturer to minimise compatibility issues.

Process Parameter Optimisation: Reasonably set manufacturing process parameters. Reducing reflow soldering temperatures or slowing the board’s heating and cooling rates during reflow can significantly reduce warping and bowing. Ensure plating uniformity and solder joint consistency.

Optimised Layout Design:

Pay particular attention during design to incorporate dead copper on layers with lower copper residue rates.

Layer stacking must be symmetrical.

Heavy components should be positioned near PCB edges where possible.

Reduce PCB dimensions or panelisation quantities.

Environmental Control:

Regulate temperature and humidity in production and storage environments.

Storage and Handling: Implement protective measures against vibration and impact to prevent mechanical damage. Enhance panel rigidity by incorporating support structures or frames.

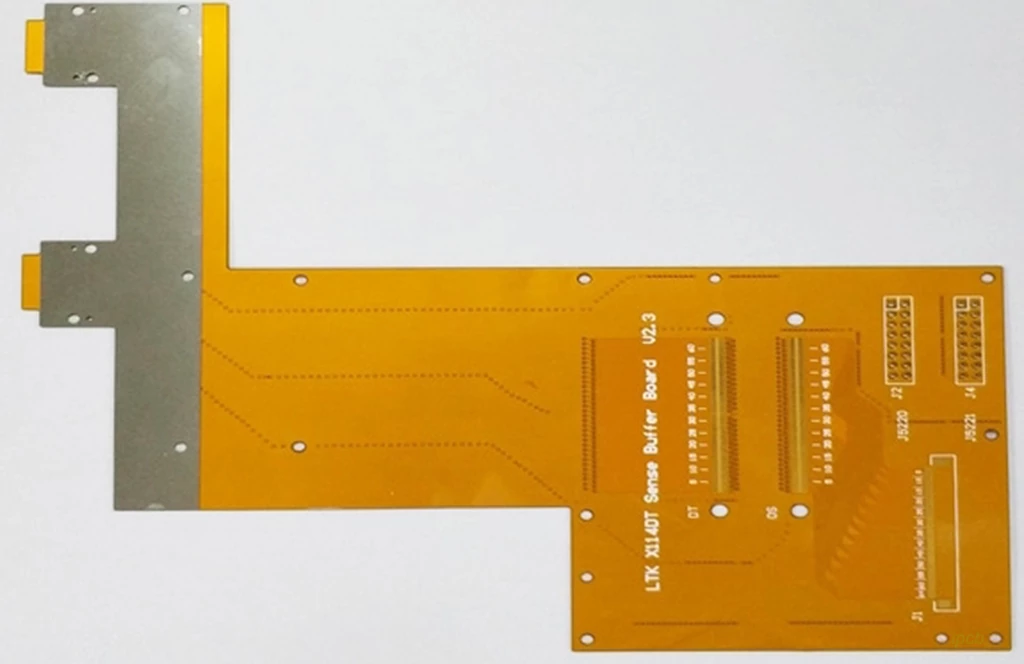

- Pad Detachment and Oxidation Issues

Pad detachment refers to the partial or complete separation of copper foil from the substrate, while pad oxidation occurs when the pad surface reacts chemically with the environment to form oxides.

Causes of Failure:

Design Issues: PCB pads designed too small or too fine, or pads left un-copper-plated and isolated. Isolated pads of smaller dimensions should be copper-plated where feasible.

Material Issues: Mismatched thermal expansion coefficients between the PCB substrate material and pad metal, where thermal stresses during soldering may cause separation between pad and substrate.

Improper Soldering Process: Excessive soldering temperatures or prolonged exposure may cause excessive pad melting or oxidation, weakening the bond with the substrate. Insufficient soldering pressure may result in poor contact between the pad and component leads. Surface contamination in the soldering area, solder mask residue, or the formation of metal oxide layers can also impair wettability.

Adverse storage and transport conditions: Exposure to humidity, high temperatures, or vibration during storage and transport may cause pad corrosion from moisture ingress, reducing bonding strength. In damp environments, water penetration at the pad-substrate interface can generate voids during soldering, leading to detachment over time. Severe vibration during transit may also cause mechanical damage to pads.

External forces: During PCB installation or operation, excessive impact, compression, or bending may cause pad detachment.

Mitigation strategies:

Optimised design: Independently designed, smaller pads should be copper-clad where feasible.

Material Selection:

Select materials with low thermal expansion coefficients, fully considering the PCB’s operational conditions.

Soldering Process Control:

Set soldering parameters appropriately to avoid excessive temperatures and prolonged exposure times. Thoroughly clean the circuit board and uniformly heat pads and pins to ensure adequate wetting.

Improve Storage Conditions:

Control temperature and humidity in PCB board and PCBA production/storage environments.

Design PCB corners with chamfers to prevent sharp edges puncturing packaging.

Use PCBs immediately after unpacking; repackage unused ones promptly to minimise exposure time.

Maintain Cleanliness:

Keep production areas and work surfaces hygienic.

Operators must handle PCBs with gloves, replacing them frequently.

Optimise surface treatment: Strictly control all parameters and specifications of surface treatment processes to ensure coating thickness and purity. Thoroughly inspect and verify surface treatment quality.

Minimise storage duration: Packaged PCB board must be utilised within their specified shelf life. PCB substrate exceeding this period require full validation prior to use.