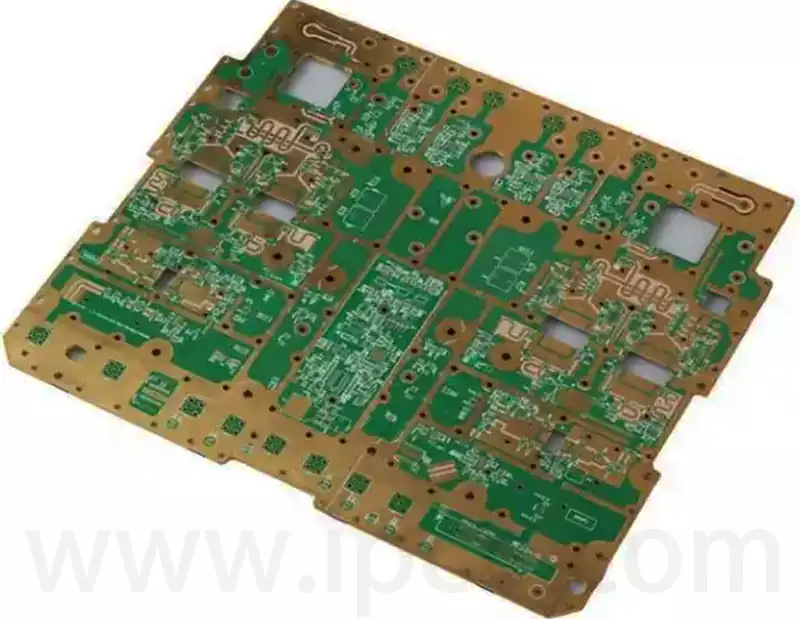

Rogers 5880 sheet is a high performance PTFE composite material with extremely low dielectric constant and loss, widely used in high frequency circuits for communications, automotive, aerospace and other applications.

Sheet Parameters:

Rogers 5880 sheet is a polytetrafluoroethylene (PTFE)-based material with a dielectric constant of 2.2 and thicknesses ranging from 0.003‘ to 0.240’. The sheets are available in copper foil thicknesses of 0.5oz. 1oz. 2oz and 3oz, and are available in gold, silver and tin finishes. Chemical silver plating and chemical tin plating.

Characteristics:

Rogers 5880 sheet has excellent high frequency performance with good dielectric constant stability. Low loss. Good impedance matching. Fast signal transmission speed. At the same time, the mechanical properties of the plate is also very good, with high strength. High stiffness. Good heat resistance. Chemical corrosion resistance and other characteristics.

Communication field: Rogers RT/duroid 5880 high-frequency circuit board has excellent communication performance, which is suitable for manufacturing all kinds of communication equipment, such as mobile phones, computers, TVs, stereos and so on.

Automotive: Rogers RT/duroid 5880 high-frequency circuit board has high heat resistance and weather resistance, which is suitable for high-frequency circuit design in automotive electronics.

Aerospace: Rogers RT/duroid 5880 HF circuit boards are used for high frequency circuit design in aerospace applications due to their excellent high temperature resistance and mechanical strength.

Medical: Rogers RT/duroid 5880 HF circuit boards are biocompatible and corrosion-resistant, making them suitable for high-frequency circuit design in medical equipment.

Key benefits of Rogers RT/duroid 5880 high-frequency circuit board include:

Extremely low dielectric constant: The dielectric constant is 2.20 ± 0.02 as measured at 10 GHz IPC-TM 2.5.5.5. This characteristic safeguards the strength of the board as required for circuit application processes and manufacturing.

Extremely low dielectric loss: dielectric loss factor of 0.0009 measured at 10 GHz IPC-TM 2.5.5.5 makes it ideal for high frequency applications.

Supports highest application signal frequencies up to Ku-band and beyond.

Moisture absorption as low as 0.02%, making it ideal for applications in high humidity environments.

Satisfies lead-free process standards and meets modern environmental requirements.

Rogers RO5870/5880 Differences and Connections:

RO5870 features a ceramic-filled polytetrafluoroethylene (PTFE) composite material with a dielectric constant of 2.33 ± 0.02 at 10 GHz and a loss factor of no more than 0.0012 for high-frequency applications ranging from 8-40 GHz. RO5880, on the other hand, is a glass-fibre-reinforced PTFE structure. With a dielectric constant of 2.20±0.02 and a loss factor of less than 0.0009, RO5880 is optimised for millimetre-wave and ultra-low-loss requirements, and is also suitable for the 8-40 GHz frequency range. Both aim to ensure good electrical performance to support high frequency and microwave communications.

The RO5870 exhibits a thermal stability of -115 ppm/°C (-50 to 150°C), while the RO5880 has a thermal stability of -125 ppm/°C. Both have a moisture absorption rate of less than 0.02%, which meets the requirements of the MIL-PRF-55110G military standard. In terms of thermal conductivity, RO5870 has a thermal conductivity of 0.22 W/m/K, while RO5880 has a slightly lower thermal conductivity of 0.20 W/m/K, which is suitable for high power density design environments.

RO5870 is mainly used in high-frequency communication and radar systems, such as the 28 GHz band antenna feeder for 5G millimetre-wave base stations, with an insertion loss of less than 0.3 dB/cm at a line width of 0.25 mm to improve the energy efficiency of base stations. In addition, its X-band radar in the range of 8-12 GHz has excellent phase stability (dielectric constant change of less than 0.02 when the temperature changes by 100°C), which is suitable for high-precision antenna applications such as airborne fire control radar.

The RO5880, on the other hand, is suitable for millimetre-wave applications and high-speed digital circuits such as vehicle-mounted 77 GHz radars, where its low loss factor supports four-channel FMCW radar modules with detection errors of less than 0.1 metres. In 20-40 GHz satellite Ka-band transponders, the RO5880’s dielectric constant consistency is controlled within ±1%, reducing signal cluster delay fluctuations and improving interplanetary communication speed. The RO5880 also meets the performance requirements of 112 Gbps high-speed backplanes with PCB alignment loss of less than 0.8 dB/inch (@56 GHz), complying with PCIe 6.0 standards.

In terms of processing technology, RO5870 is recommended to use tungsten carbide drills with 24,000 RPM and 3 m/min receding rate to avoid interlayer stripping of PTFE material, while Rogers 5880 often adopts UV laser cutting technology with a wavelength of 355 nm, power of 8 W, and aperture machining accuracy control within ±25 μm. For surface treatment, both use a chemical nickel gold plating (ENEPIG) process with a thickness of 0.15 to 0.3 μm to reduce the skin effect in the millimetre wave band. For soldering, the peak temperature is 260°C for RO5870 and 245°C for RO5880 to prevent thermal deformation of the PTFE material.

Specification standards include sizes of 12 x 18 inches and 18 x 24 inches, with a wide selection of thicknesses from 0.127 mm to 3.175 mm, and standard copper thicknesses are generally available in 0.5 ounce and 1 ounce grades to meet different application requirements.

Compared with RO5870, Rogers 5880 has superior performance in dielectric constant, loss factor and applicable millimetre-wave frequency bands, which is especially suitable for application scenarios that require very high signal quality and transmission speed. Reasonable processing technology and diversified specification options further guarantee its stability and reliability in high-frequency circuit design.