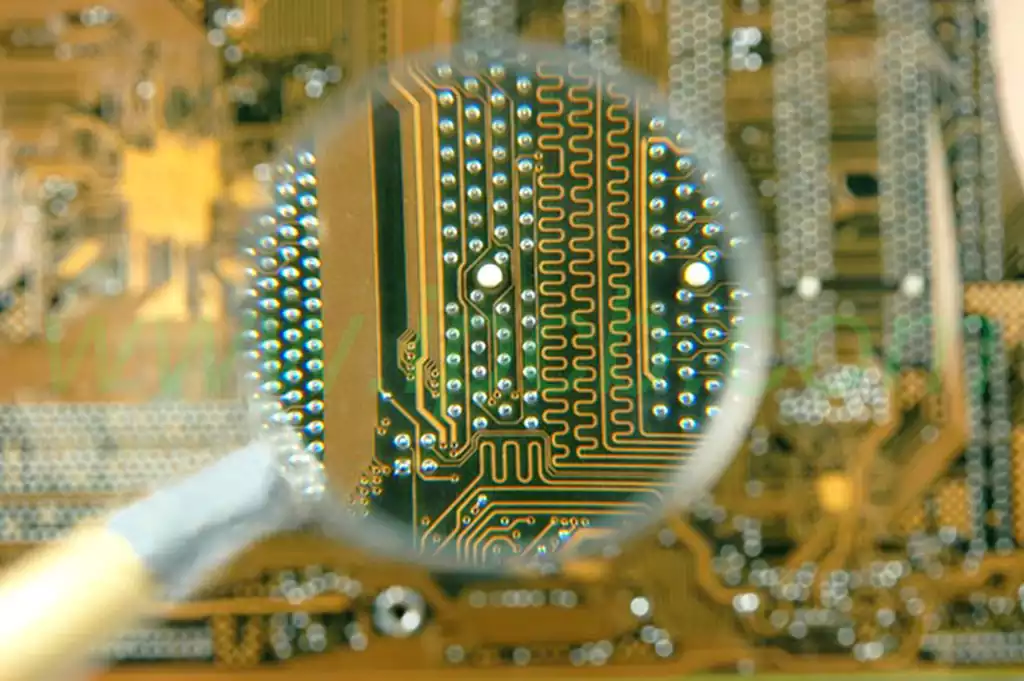

What is Flex PCB? A Flex PCB is a printed circuit board that can be bent and folded to accommodate different shapes of materials, and it can be bent and twisted without easily breaking the material. Flex PCBs are usually made of elastic materials such as polyurethane and rubber. These materials are used in a wide variety of products, such as electronic devices, automotive parts, and medical equipment. Because flexible boards can be bent into different shapes, it is easier to use them for manufacturing products that require bending.

Flexible circuit board production process

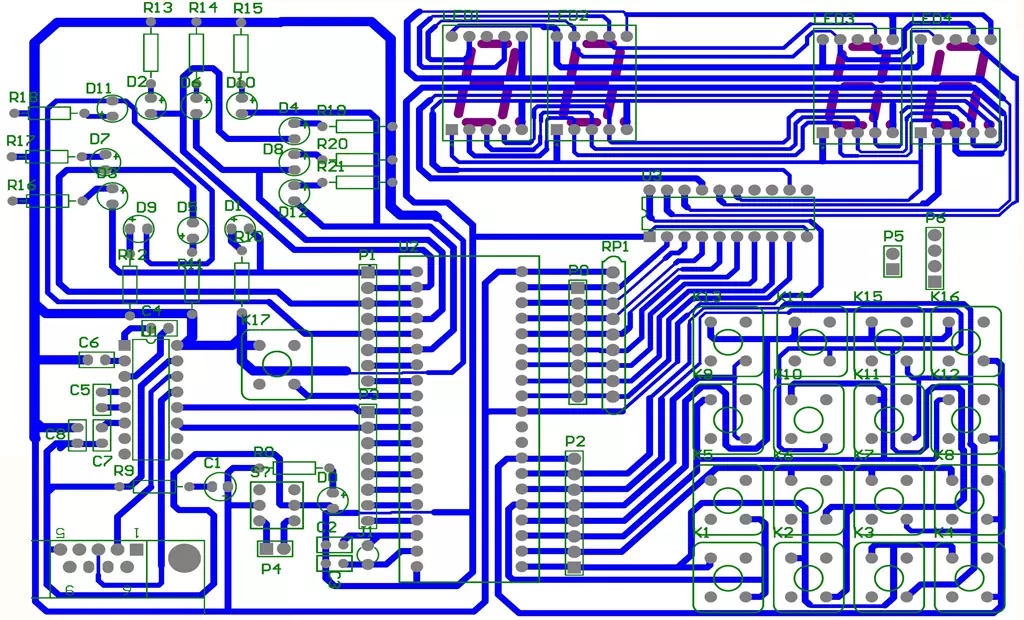

1.Design Drawing Production

Flex pcb is flexible, bendable circuit boards that require design drawings to be made. Design drawings are usually produced using electronic design automation (EDA) software, including circuit layout, wiring paths, component mounting locations and dimensions. Design drawings to meet the functional requirements of the circuit board, but also consider the limitations of materials and production processes.

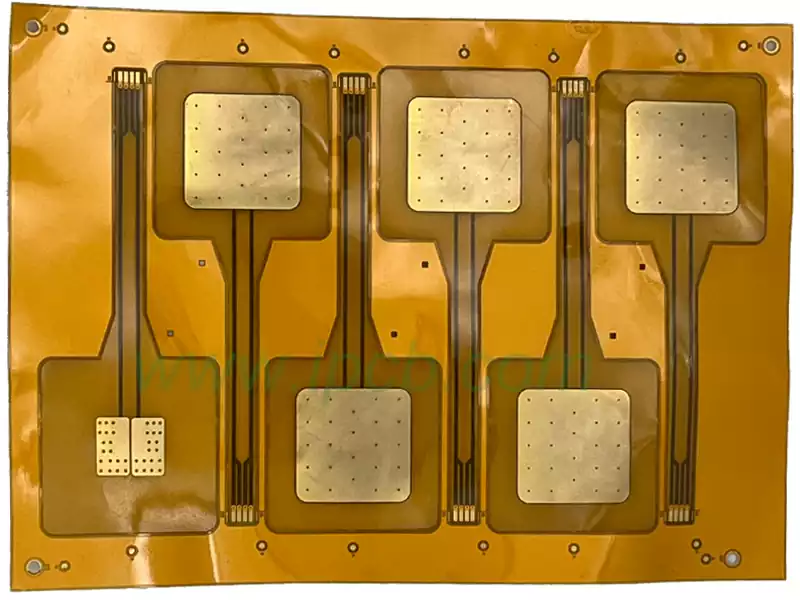

- Material Preparation

Flexible circuit board materials generally include conductive coating film, insulating film, adhesives and cover layers. These materials should be selected and purchased in accordance with the design requirements to ensure the quality and performance of the circuit board. Conductive coating film and insulating film should be cut, adhesive and cover layer should also be cut according to the design size. - Printing

The conductive coating film through the printing technology to the insulating film to produce circuit patterns, the general choice of screen printing and compression printing. Coated film through the printing production of wires, and in the insulating film above the perpendicular to the circuit layout arrangement. After the completion of printing the circuit needs to be exposed to ensure that the circuit can meet the specifications of the product. - Cutting and molding

After the completion of printing, the circuit board also needs to be cut and molded, generally using laser cutting technology. In the cutting and molding, pay attention to the size and shape of the precision, to ensure the stability and reliability of the circuit board. - Quality Inspection

Production process, the need for electrical and mechanical testing of circuit boards to ensure that the quality of circuit boards to meet the requirements, mainly in the production of circuit boards to see whether there are short circuits, open circuits and other problems and the voltage of the conductor to reduce the situation. - Assembly test

After testing the qualified flexible circuit boards also need to be assembled, mainly circuit boards and components, plugs and other assembly, and testing. Tests mainly include electrical performance tests, reliability tests and so on.

What is a rigid board?

A rigid board is a material, usually referred to as a hard material, that cannot be bent or twisted. This material is usually more suitable for applications that require strong support, such as machine parts, building materials, etc. Rigid boards are usually made of metals or plastics that are very hard and durable in nature, providing stability and strong support for the object they are supporting.

Difference between flexible PCB and rigid board:

- Wire carrying capacity: Compared with rigid circuit boards, flexible circuit boards have relatively poor heat dissipation performance. Because the heat dissipation of flexible circuit boards is taken into account, it is necessary to allow extra width or spacing for the wires.

- Shape. Often, choosing a rectangular shape can be a good way to save substrate and there should be enough available margins near the edges. Sharp inside corners may cause the board to tear. Therefore, FPC lead width and spacing should be minimized and transitions must be as smooth as possible. Sharp corners naturally concentrate stress and lead to lead failure.

- Flexibility: The flexibility of a rigid board cannot be compared to that of a flexible board. For a large number of bending cycles, flexible circuit boards have better performance.

Flex PCB and rigid boards have their own characteristics, the former is known for its flexibility and the latter is known for its robustness. They play an important role in different areas, and jointly promote the booming development of the electronics manufacturing industry.