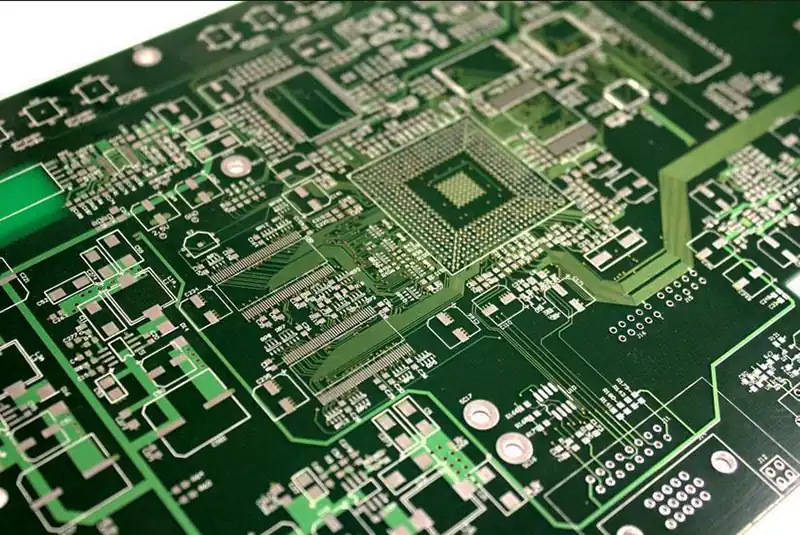

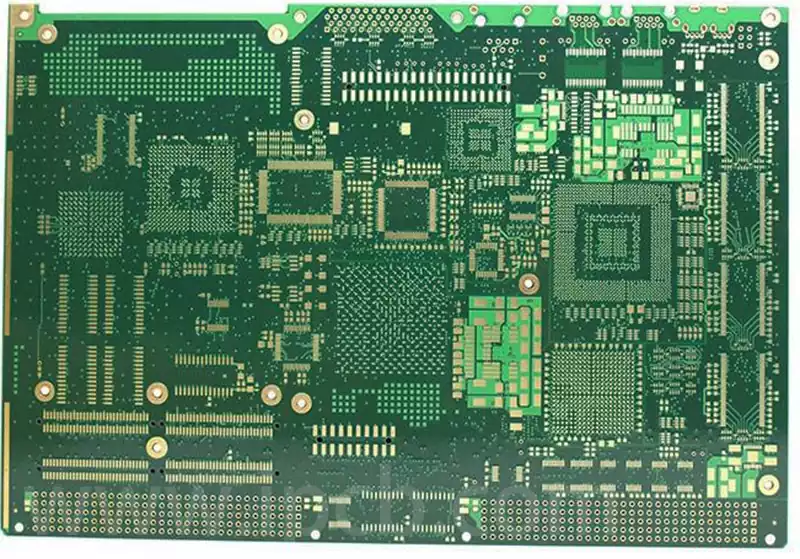

Leadless chip carrier refers to a chip substrate material that does not contain lead. Traditional chip carriers often use leaded materials because leaded materials have high plasticity and are easy to process during manufacturing, but leaded chips are harmful to the environment and the human body. Leadless chip carrier is widely used in the manufacture of various electronic devices, such as PCB boards, hard disc drives, communication devices, home appliances, and automobiles.

Leadless chip carrier has the following characteristics compared with traditional leaded chips:

- Environmental protection: the manufacturing and use of leaded chips will release harmful substances, which are harmful to the environment and human body. Leadless chip carrier does not require the use of lead in the production process, so they are more in line with environmental requirements.

- Strong resistance to cold soldering: Leadless chip carrier is connected by lead-free solder, which can avoid breakage caused by sudden cooling during the cooling process.

- High-temperature resistance: leadless chip carrier has better performance in high-temperature environments and are less likely to be affected by high temperatures, thus improving the service life of the chip.

Difference between leadless and leaded chips

- Environmental friendliness

Leadless chip carrier is more environmentally friendly than leaded chips because lead is a toxic substance that can harm the environment and human health. The non-lead solder used in Pb-free chips is not harmful to the environment and human health. - Circuit performance

Although the use of lead-free solder can achieve the purpose of environmental protection, the ratio of its alloy with lead, the soldering time and the soldering temperature will have different degrees of impact on the circuit performance. Some lead-free solder has a higher melting point, which will increase the difficulty of the soldering sequence, resulting in some solder joints are not solid, poor contact between circuit layers, affecting the durability of the chip. - Maintenance costs

Leadless chip carrier requires the use of special equipment and processes compared to leaded chips, which makes the associated equipment and processes more costly. In addition, the maintenance cost of leadless chip carrier is higher due to the relatively high cost of lead-free solder joints.

Methods of distinguishing between lead-free and leaded chips

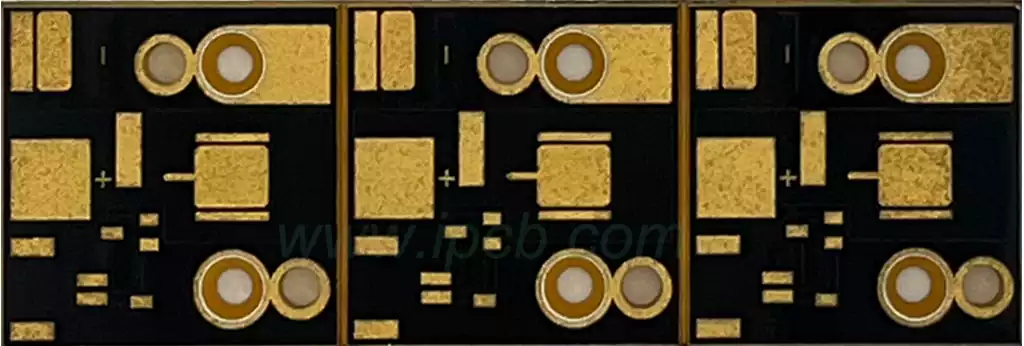

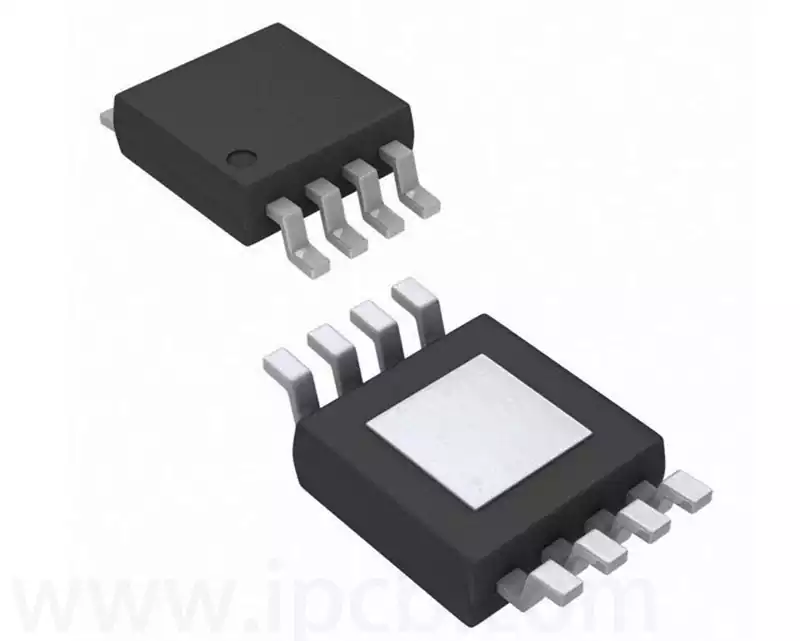

- Appearance Distinction Method

Appearance-wise, the pads of leadless chip carrier is brighter than those of leaded chips, with a more uniform colour and a smoother surface. The pads of leaded chips are rougher and the colour is not uniform. - Pattern marking method

Now many chip makers will add the word LF (Lead-free) on top of the leadless chip carrier, indicating that the chip is lead-free. If there is no such word, it is usually a leaded chip. - X-ray machine testing method

The chip will be placed under the X-ray machine scanning, leadless chip carrier and leaded chips have different pad structures, so you can distinguish them through X-ray machine testing. - Testing Instrument Method

At present, there are some instruments on the market that are specially used to test the lead content of chips, which can be tested quickly and accurately. This method requires professionals to use, the cost is also relatively high.

Leadless chip carrier as an environmentally friendly and superior performance materials, is gradually replacing the traditional leaded chips, becoming the mainstream of electronic equipment manufacturing. It is not only harmless to the environment and human health during production and use, but also shows excellent advantages in cold soldering resistance and high temperature tolerance, which significantly improves the reliability and service life of the chip. However, the promotion of leadless chip carrier also faces some challenges. Due to the characteristics of lead-free solder, it may have some impact on circuit performance and increase maintenance costs. Nevertheless, these issues are gradually being addressed as technology continues to evolve.