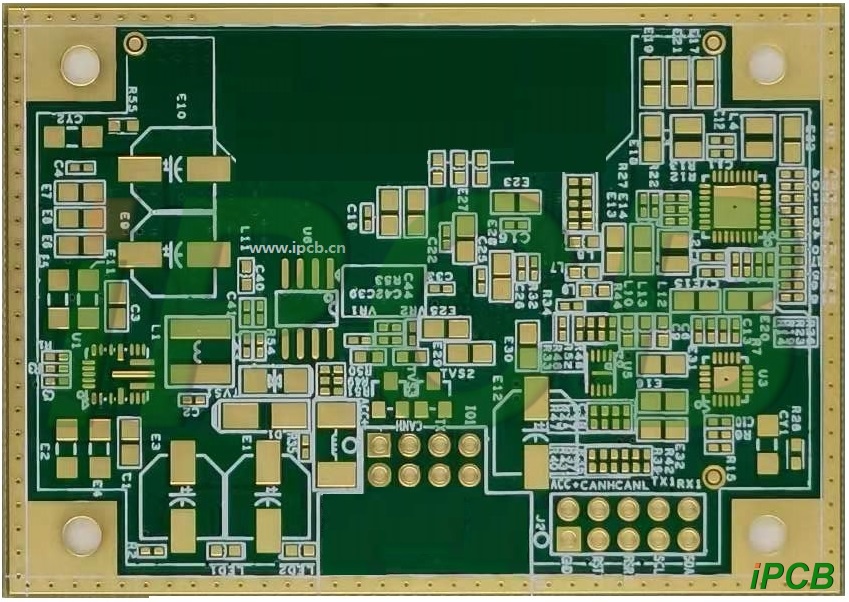

The surface treatment process of PCB circuit boards is crucial to their performance and environmental credentials. Among these, the tin-plating process is widely favoured for its cost-effectiveness and solderability. Tin-plating can be categorised into leaded and lead-free variants based on lead content, exhibiting significant differences in composition, soldering characteristics, environmental requirements, and application scenarios.

What distinguishes lead-free from leaded tin-plating for PCB circuit boards?

- Lead-free tin-plating constitutes an environmentally compliant process, free from the hazardous substance ‘lead’. Its melting point is approximately 218°C. The tin bath temperature must be maintained between 280-300°C, whilst wave soldering temperatures should be controlled around 260°C. Reflow soldering temperatures should be maintained between 260-270°C.

- Leaded solder is not an environmentally friendly process, containing the hazardous substance ‘lead’. Its melting point is approximately 183°C; the solder pot temperature must be controlled between 245-260°C; wave soldering temperatures should be maintained around 250°C; reflow soldering temperatures should be controlled between 245-255°C.

- Visually, leaded solder appears brighter on the surface, whereas lead-free solder appears duller; leadfree pcb circuit boards exhibit slightly poorer wettability than leaded boards.

- Lead content in lead-free solder does not exceed 0.5%, while leaded solder contains up to 37% lead.

- Lead enhances the reactivity of solder wire during the soldering process, making leaded solder wire relatively easier to use than lead-free solder wire. However, lead is toxic and prolonged exposure is detrimental to human health. Lead-free solder has a higher melting point than leaded solder, resulting in significantly stronger solder joints.

- In PCB circuit boards surface treatment, the cost of lead-free and leaded hot-dip tinning is typically identical, with no price distinction.

The leaded hot-dip tinning process involves immersing the pcb circuit board in molten tin-lead alloy solder, coating the exposed copper surfaces of the PCB circuit boards.

Excess solder is then removed using high-pressure hot air to achieve a smooth surface finish.

Advantages: Relatively low cost, excellent soldering performance, forming stable joints with various electronic component leads. Lead-plated boards also exhibit superior mechanical strength and surface finish.

Disadvantages: Contains lead and other heavy metals, posing significant environmental hazards and failing to meet eco-friendly standards, rendering it non-compliant with ROHS testing. Furthermore, the surface finish is suboptimal for soldering fine-pitch pins and extremely small components. Tin balls may form during PCB circuit board processing, potentially causing short circuits in fine-pitch component connections. In double-sided SMT processes, during high-temperature reflow soldering of the second side, the sprayed tin may remelt, forming solder balls or spherical solder points that further compromise surface flatness and soldering quality.

Applicable scenarios: It retains some application in products with lower environmental requirements, stringent cost control, and less demanding soldering precision, such as certain traditional consumer electronics and low-end industrial equipment. However, with increasingly stringent environmental regulations, the scope of leaded spray tinning is gradually diminishing.

The principle of lead-free spray soldering is similar to leaded spray soldering, differing only in the use of lead-free solder alloys to meet environmental standards.

Advantages: It offers excellent soldering performance and strong solderability, accommodating the soldering requirements of most electronic components. Additionally, it complies with environmental standards and passes ROHS testing without issue.

Disadvantages: The surface brightness is slightly duller compared to leaded spray soldering. It similarly suffers from poor surface flatness, rendering it unsuitable for soldering fine-pitch leads and small components. It is prone to solder balling and, in double-sided SMT processes, also faces issues with solder balls and surface irregularities. Furthermore, the lead-free spray soldering process demands higher standards of equipment and process control, resulting in relatively increased costs compared to leaded spray soldering.

Suitable applications: Widely employed in electronics with stringent environmental requirements, such as consumer electronics, automotive electronics, and medical devices. In these sectors, products must comply with relevant environmental regulations, making lead-free spray soldering a vital choice for meeting both soldering needs and eco-friendly standards.

How to distinguish between lead-free and leaded PCB circuit board surfaces

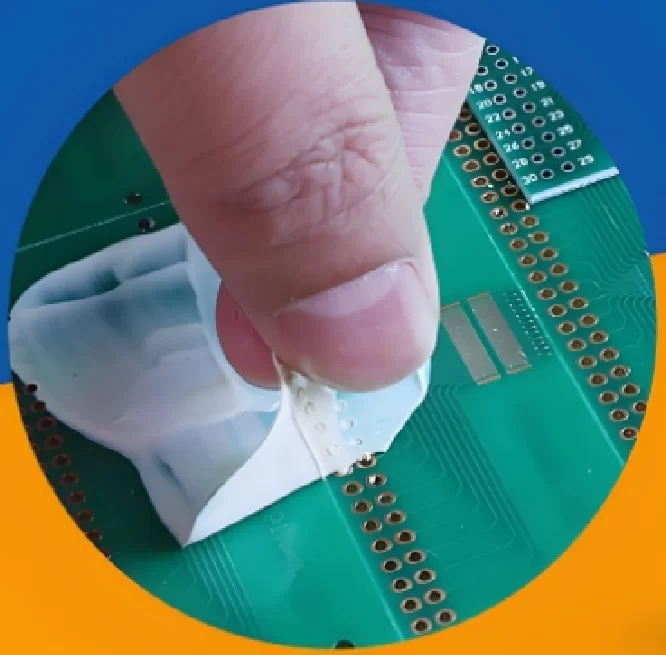

Visually, leaded surfaces appear bright white, whereas lead-free surfaces exhibit a pale yellow hue (due to copper content in the solder).

Tactilely, touching the solder reveals that lead-free paste leaves faint yellow marks on the skin, while leaded solder leaves black residue.

Compositionally, leaded solder primarily contains tin and lead, whereas lead-free solder has lead content below 500 parts per million (ppm). Lead-free variants typically incorporate tin, silver, or copper metallic elements.

Regarding application: Leaded solder is suitable for soldering leaded products, where all technical tools and components used are leaded. Lead-free solder paste is suitable for soldering products destined for export to regions such as Europe and America, where all technical tools and components used must be lead-free.

The selection of tin-plating processes for pcb circuit boards, whether lead-free or leaded, necessitates a comprehensive assessment of cost, performance, and environmental regulations. Whilst leaded tin-plating retains applications in specific scenarios, lead-free tin-plating has become the mainstream approach. This approach meets increasingly stringent environmental requirements and ensures the market competitiveness of products.