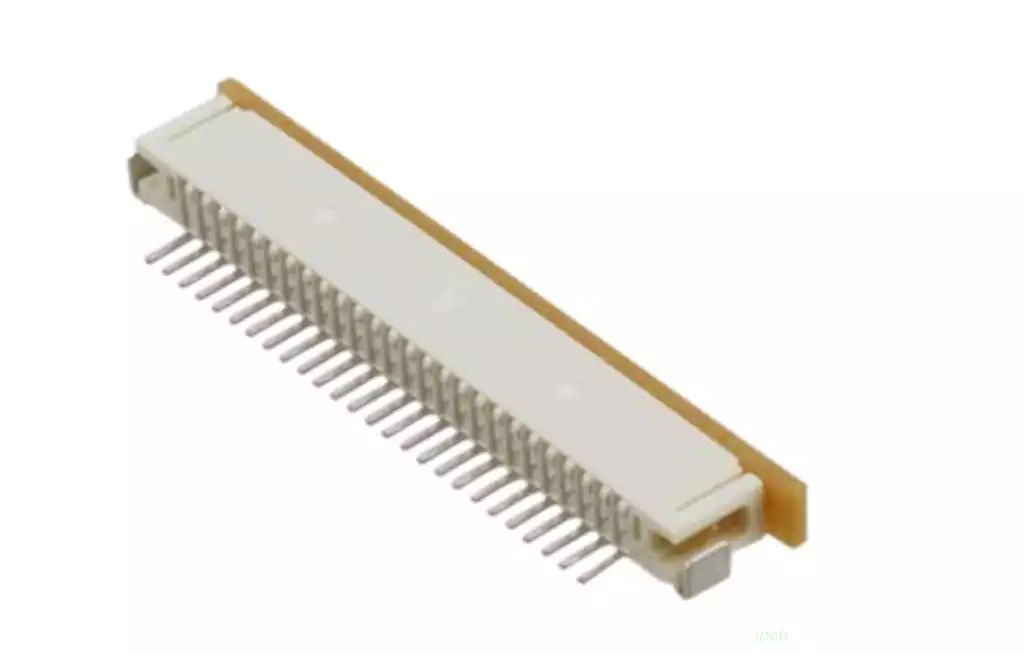

FFC connectors and FPC connectors are often confused. Although both are flexible cable connectors, but FFC connectors and FPC connectors are still a certain degree of difference. FFC is a flexible flat cable (Flexible Flat Cable) connectors, FPC is a flexible printed circuit (Flexible Print Circuit). In terms of the manufacturing of the two, the way they line formation is different.

ffc connector and fpc connector difference

- Definition of different. FPC connector (Flexible Printed Circuit board) is a flexible printed circuit board, FFC connector (Flexible Flat Cable) is a flexible flat cable connector, one is a circuit board, the other is a flat cable.

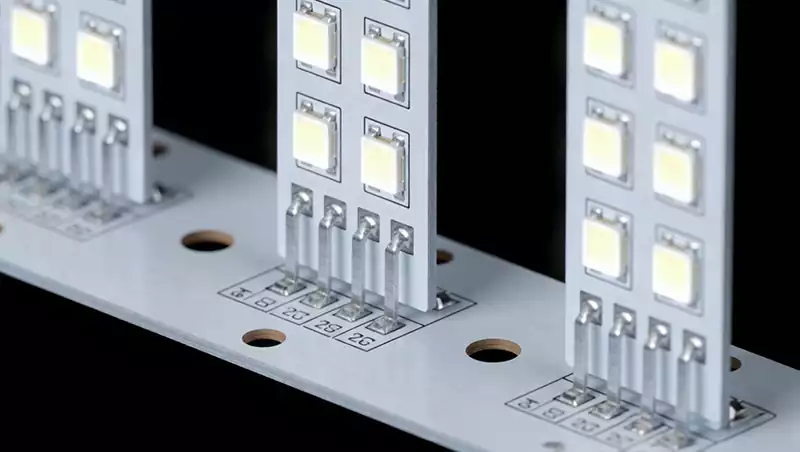

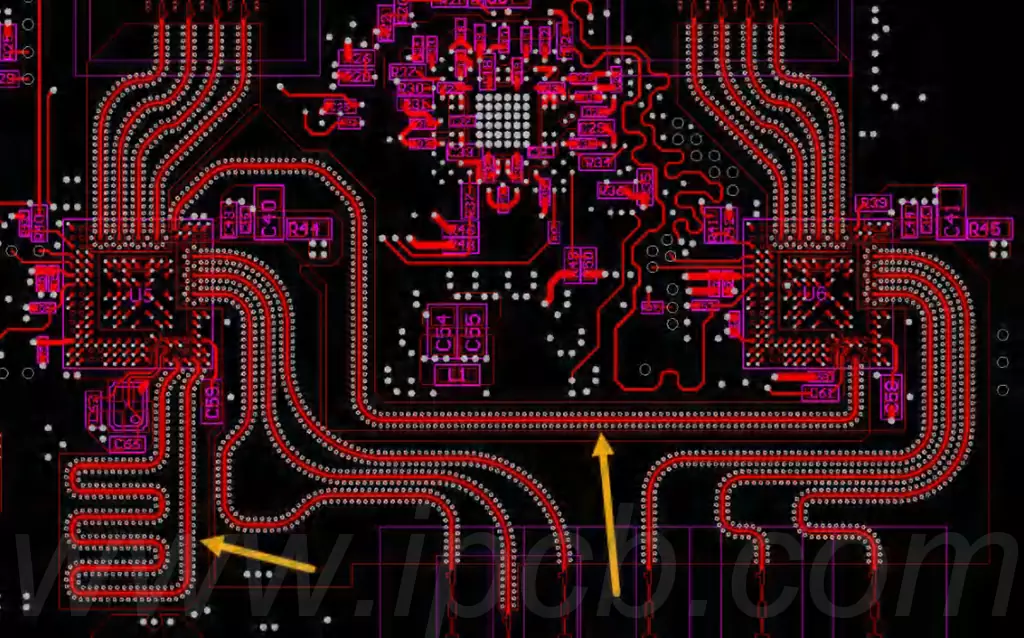

- Line formation is different. fpc is a chemical etching way to FCCL (Flexible Copper Clad Laminate) processing to get the line away from the different single-sided and double-sided and multi-layer structure of the flexible circuit board; FFC is the upper and lower two layers of insulating foil film in the middle of the flat copper foil, the finished product is simpler, the thickness of thicker.

- Price difference. Due to the nature and design of the product, so the ffc connector price is much lower than the fpc connector. But thanks to lower production costs, more companies prefer ffc related designs.

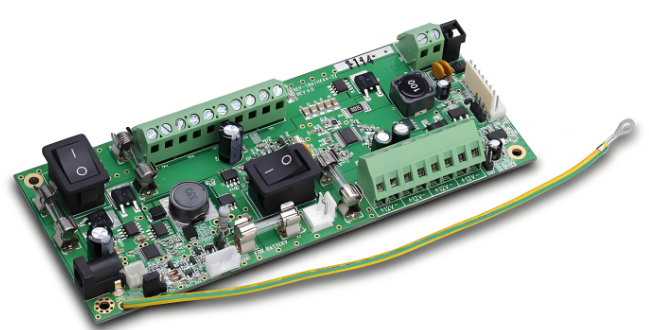

- Application differences. Due to the differences in performance and structure, FFC and FPC are different in application. ffc is mainly used to connect circuit boards between electronic devices, such as computers, communication equipment, medical equipment, industrial control equipment, etc. FFC is mainly used to connect circuit boards between electronic devices, such as computers, communication equipment, medical equipment, industrial control equipment. Due to its high degree of flexibility and folding resistance, it can be adapted to a variety of complex equipment layouts and space constraints.

FPC, on the other hand, is mainly used in the manufacture of flexible circuit boards in various electronic devices, such as cell phones, tablet PCs, wearable devices, and so on. Due to its multi-layer circuitry and complex circuit layout capabilities, it can realize higher circuit integration and more complex circuit functions, making electronic devices thinner, lighter, more efficient, and more multi-functional.

The similarities between ffc connectors and fpc connectors

- The same application areas. ffc connectors and fpc connectors are widely used in liquid crystal displays, scanners, plotters, scanners, copiers, stereos, fax machines and other electronic equipment.

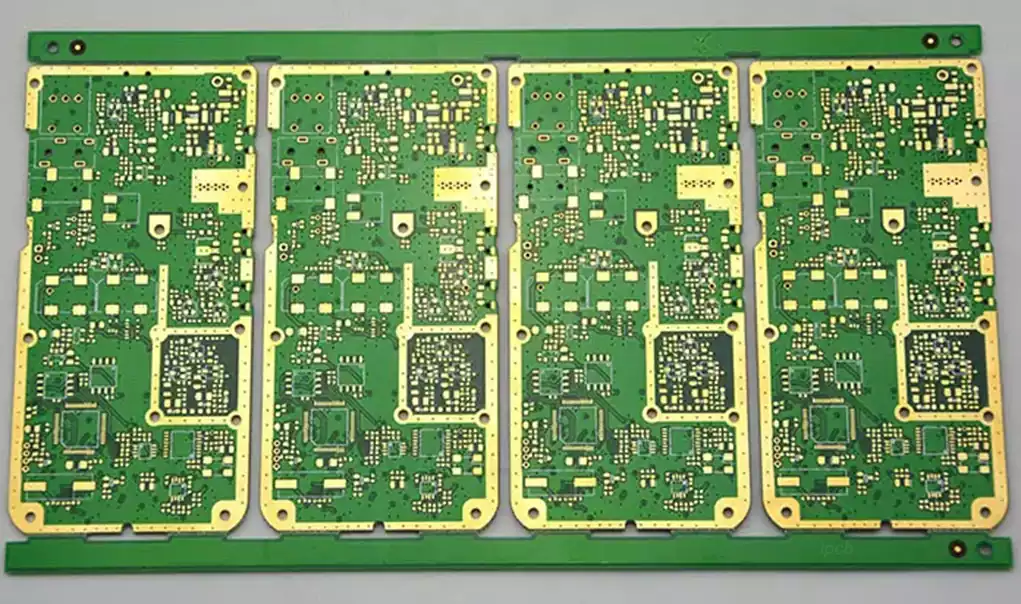

- The same characteristics. ffc connectors and fpc connectors have excellent flexibility, application flexibility, folding, manufacturing miniaturization, compact, high density integration, space saving, simple wiring and other characteristics.

Overall, FFC and FPC have significant differences in structure, performance and application. As a professional electronic connector manufacturer, we suggest that when choosing to use FFC or FPC, the decision should be based on specific equipment requirements and application scenarios. Factors to be considered in the selection include the complexity of the device, space constraints, circuit integration and signal transmission quality.