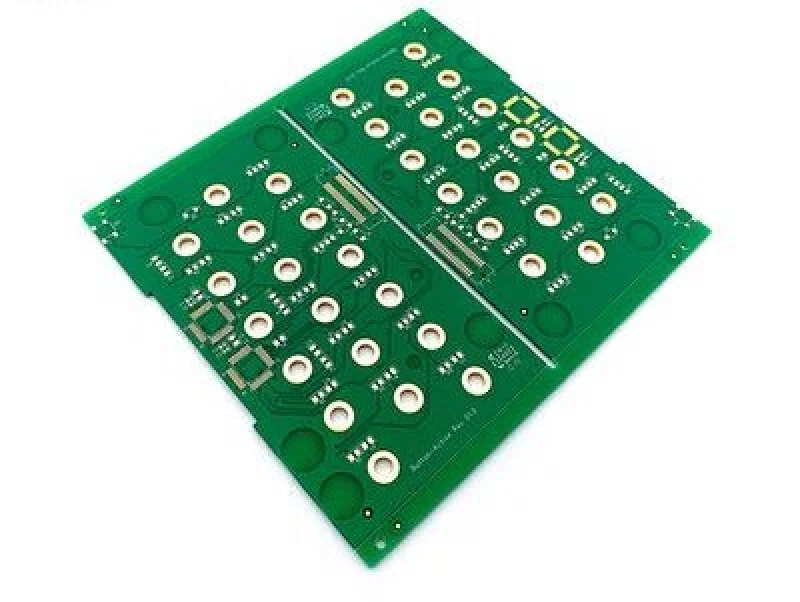

The choice of FR4 PCB color is often bound by ingrained assumptions: green is seen as the “king of cost performance,” black carries an aura of “high-end, high performance,” while red and blue are regarded as signatures of industrial equipment. In PCB selection discussions, this seems almost axiomatic. Yet few people stop to ask whether these color differences are merely aesthetic coincidences or whether they are intrinsically linked to the performance of the FR4 substrate itself. Once we look beyond the “colorful outer layer” of the solder mask and examine its true relationship with FR4 performance, several industry realities emerge: solder mask color has never been a determining factor in FR4 performance, but it can quietly influence final product reliability through process execution and application-specific suitability.

A common misconception about FR4 PCB color lies in equating the color of the solder mask with the color of the substrate. In reality, most mainstream PCB substrates, including FR4, are naturally light yellow or pale brown glass-fiber/epoxy composites. The colors we see on FR4 PCBs all come from the solder mask layer (commonly called solder mask ink) applied on top of the substrate. This layer serves essential functions—electrical insulation, prevention of solder bridging, and protection of copper traces from oxidation. Its color is determined solely by the type and ratio of pigments used, and has no direct connection to the core composition of the FR4 material.

The “color formula” of different solder masks essentially reflects pigment differences. Green solder mask became the industry standard not because it is inherently better matched to FR4, but because early PCB manufacturing found green pigments (typically chromium green or phthalocyanine green) to be low in cost, stable in processing, and well balanced in contrast against copper traces. This contrast significantly improves defect recognition efficiency in AOI (automated optical inspection) systems, making green ideal for mass production. In practice, green solder mask achieves batch production yields of up to 95%, typically 3–5% higher than black solder mask.

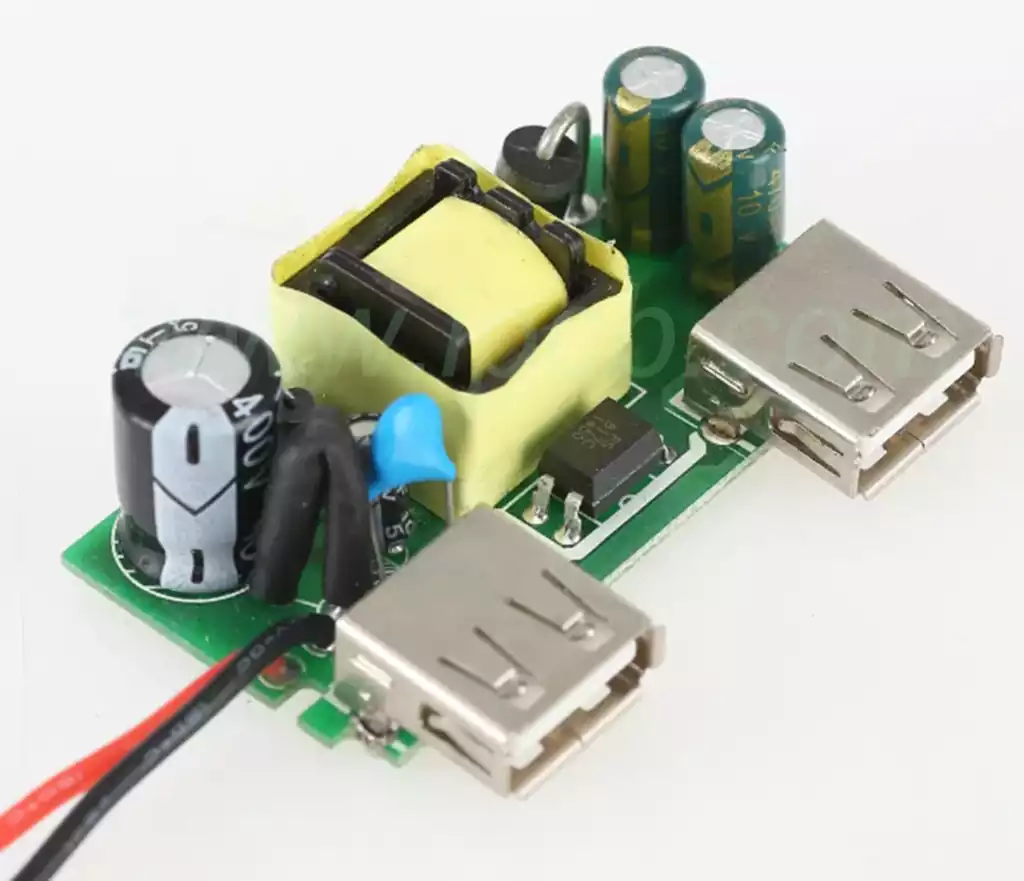

Black solder mask, by contrast, is driven largely by demand for a premium appearance. Using carbon black as the primary pigment, it offers over 95% light blocking, delivering a sleek and understated visual effect favored in high-end graphics cards and consumer electronics. However, carbon black exhibits slight electrical conductivity. If pigment concentration is not tightly controlled, the insulation performance of the solder mask can be compromised. As a result, black solder mask places stringent demands on process precision, with coating thickness variation often required to be controlled within 5 μm. Red and blue solder masks typically rely on organic dye pigments and are primarily used for functional differentiation—for example, red boards for power modules and blue boards for control modules in industrial cabinets. White solder mask, with its high reflectivity, is commonly used for LED backlight boards, but suffers from poor yellowing resistance, with discoloration rates reaching up to 20% after 1,000 hours of damp heat testing.

It is important to emphasize that regardless of color, the core composition of solder mask materials is epoxy resin; only the pigments differ. This fundamental fact means that solder mask color cannot alter the inherent properties of the FR4 substrate and therefore cannot be a decisive factor in FR4 performance.

To assess whether solder mask color affects FR4 performance, one must first clarify FR4’s key performance metrics: electrical performance (impedance control and signal integrity), mechanical performance (flexural strength and structural stability), thermal performance (glass transition temperature, Tg), and long-term reliability (resistance to heat, humidity, and aging). These attributes are determined by the FR4 substrate and the design and manufacturing process, not by solder mask color.

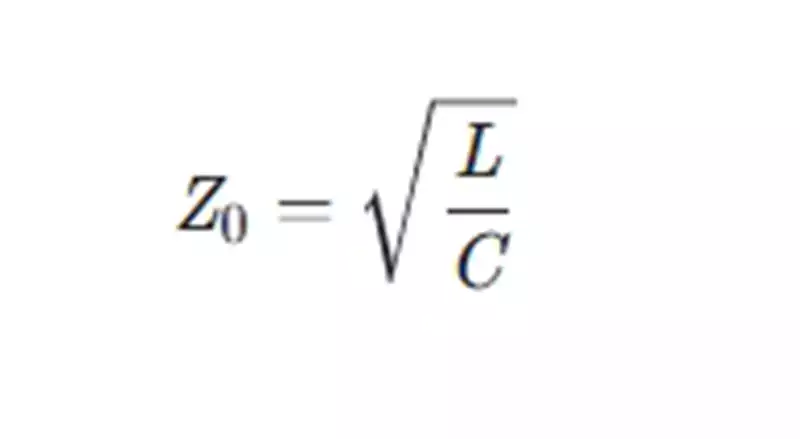

Electrical performance is the core strength of FR4. Its primary influencing factors include dielectric constant (Dk), dissipation factor (Df), copper foil quality, and trace design. Standard FR4 typically has a Dk of approximately 4.2–4.8, suitable for low- to mid-speed signal transmission. High-frequency applications require high-Tg FR4 (Tg ≥170 °C) or specialized materials to reduce signal loss. Impedance matching depends on precise control of copper thickness, trace width, and dielectric thickness—not on solder mask color. Even in high-frequency designs, the impact of solder mask on signal behavior is minimal; the dielectric constant differences among different colored solder masks appear only in the third decimal place, far smaller than the difference between standard FR4 and high-frequency substrates.

Mechanical and thermal performance are likewise governed by the substrate. FR4 typically exhibits flexural strength above 300 MPa, sufficient for most installation requirements. Thermal performance is defined by Tg: standard FR4 has a Tg around 130 °C, while high-Tg variants withstand temperatures above 170 °C, enabling them to endure SMT reflow soldering at 260 °C and long-term high-temperature operation. None of these characteristics are affected by solder mask color. Real threats to thermal stability stem from substrate aging, moisture absorption, or manufacturing defects—such as reduced insulation after moisture uptake, thermal stress cracking, or even delamination and “popcorning.”

Heat dissipation is another area often misunderstood in relation to color. While it is commonly believed that “black absorbs heat and dissipates it better,” the reality is that solder mask thickness is only 10–30 μm, with a thermal conductivity of just 0.2–0.3 W/m·K—far lower than copper (401 W/m·K) and even lower than FR4 itself. PCB thermal performance depends primarily on substrate thermal conductivity, copper distribution, and thermal design features. The temperature difference attributable to solder mask color is negligible in most applications, becoming noticeable only under extreme conditions such as prolonged outdoor exposure to intense sunlight, where differences may reach a few degrees Celsius.

Although solder mask color does not directly determine FR4 performance, it can indirectly influence final product reliability by affecting manufacturing processes and inspection accuracy—forming an implicit “color–process–reliability” chain. This indirect impact is the real basis for color selection in different application scenarios.

Process difficulty is the most significant hidden factor. Green solder mask benefits from the highest level of process maturity: uniform pigment dispersion, low risk of bubbles or pinholes, and excellent compatibility with AOI systems. This combination minimizes missed defects and results in the highest production yields and the lowest latent failure rates. Black solder mask, on the other hand, complicates AOI inspection by masking fine trace defects and requires tighter control of insulation properties. If parameters are poorly managed, insulation resistance may decrease—typically around 10¹² Ω·cm for black solder mask, compared with about 10¹³ Ω·cm for green—potentially affecting long-term stability.

In specific application environments, color choice can serve as a supplementary reliability factor. In high-voltage power electronics, blue solder mask can be advantageous, offering a volume resistivity of up to 10¹⁴ Ω·cm—an order of magnitude higher than green—allowing reduced creepage distances while maintaining insulation safety and saving board area. For high-temperature environments such as automotive engine compartments, red solder mask performs better: it can withstand short-term temperatures up to 300 °C, with a cracking rate of only 1% at 280 °C testing, compared with 3% for green and 5% for black, and shows a peel-off rate of just 0.5% during long-term operation at 150 °C. For outdoor LED applications using white solder mask, yellowing resistance must be carefully considered, as long-term discoloration affects not only appearance but also insulation performance, necessitating specialized anti-yellowing pigments.

Reminder and maintenance efficiency further illustrate the indirect impact of color on “in-use performance.” Green solder mask paired with white silkscreen offers the highest contrast, enabling rapid identification of traces and components during troubleshooting. Black solder mask can hinder visual inspection, while light-colored solder masks with similarly light silkscreen reduce readability. In complex industrial or medical systems, using different colors to distinguish functional modules—such as red for power boards and blue for control boards—can significantly shorten maintenance time and improve overall system efficiency.

In FR4 PCB selection and application, it is far more productive to focus on substrate quality, process precision, and application suitability than to dwell on perceived “performance differences” among colors. These core factors ultimately determine reliability. Thoughtful color selection merely adds a layer of application-oriented optimization. Looking ahead, advances in solder mask materials will continue to lower process barriers across colors, but their auxiliary role will remain unchanged. The true determinants of FR4 performance will always reside in the substrate and the robustness of the manufacturing process.