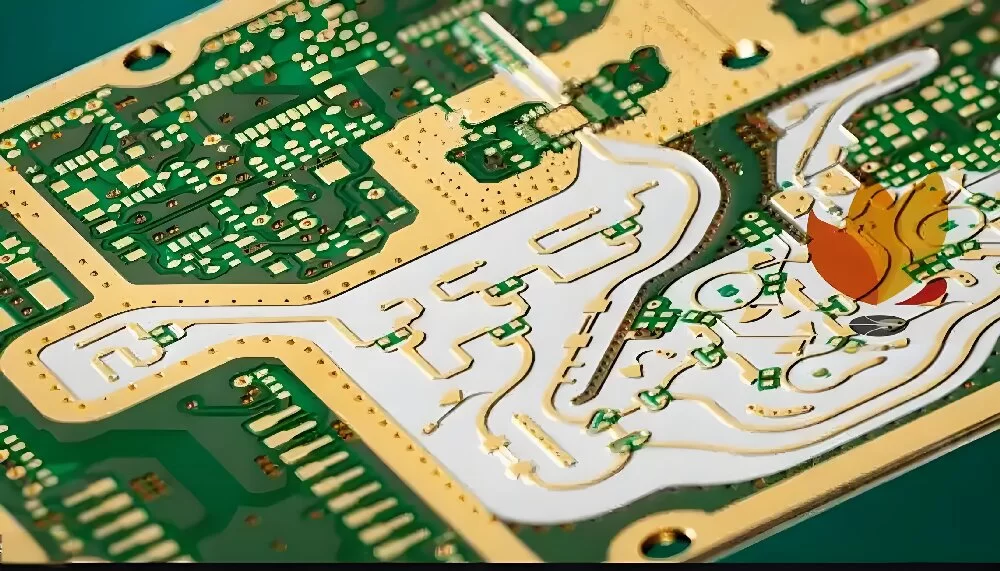

What is a Gerber file?Gerber, also known as “light drawing”, serves as an intermediate medium for converting designed graphic data into PCB or FPC manufacturing, i.e., a CAD-CAM data conversion format standard, the main purpose of which is PCB or FPC board drawing, which is ultimately used by FPC manufacturers to complete PCB production. The main use is PCB or FPC board drawing, and ultimately by the FPC manufacturer to complete the production of PCB.Gerber file is the most common and most widely used file format in the electronic assembly industry.Gerber file is the standard format of EIA, divided into RS274-D and RS274-X two kinds of RS274-X is the extension of the RS274-D. Gerber file is a series of ASCII files, which is the most common and most widely used format in the electronic assembly industry.

Gerber files are a series of ASCII vector format files used to define PCB design specifications. They are generated using electronic design automation (EDA) or computer-aided design (CAD) tools and provide information such as board configuration parameters, aperture descriptions, XY coordinate positions, and drawing instructions. Configuration details include the size and shape of the PCB to be fabricated.

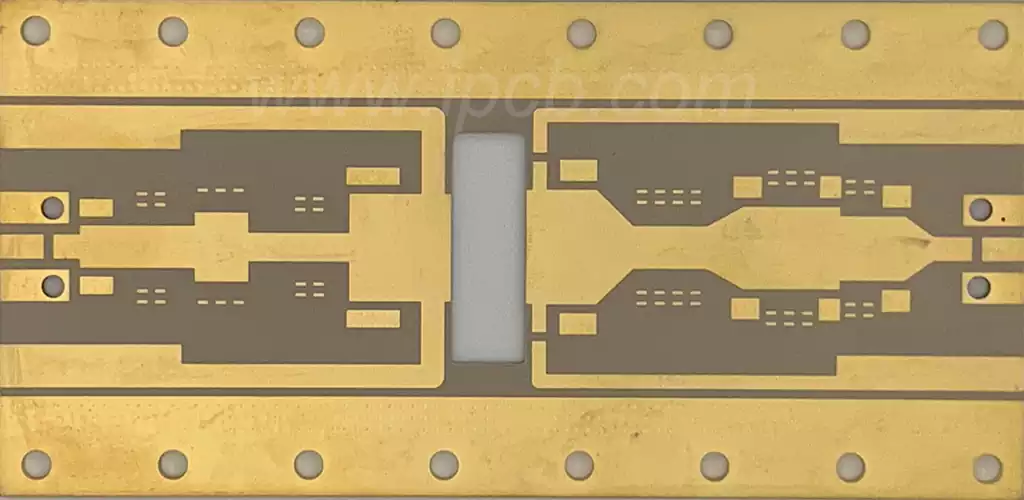

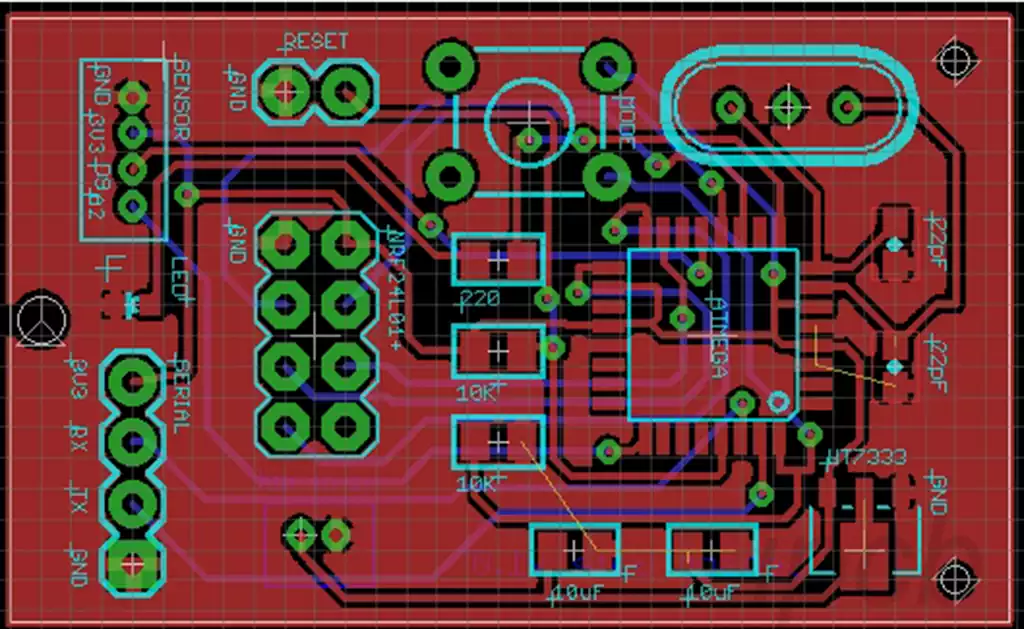

Each layer of board information is recorded in separate files for defining components such as copper traces, pads, vias, soldermasks, silkscreens, logos, etc. The Gerber file indicates the XY coordinate location of each geometric shape, and instructions are used to draw these shapes on the solid board.

The basic components of a Gerber file include: board dimensions, shape,top assembly,top silkscreen,top soldermask,top paste,top copper,internal signals, inner layer, bottom copper, bottom paste, bottom soldermask,bottom silkscreen,bottom assembly,and fabrication information (to provide information on stackups, drilling details, cutouts, etc.).

How to verify the error of Gerber file

- Manual verification: micro-view scrutiny

Visual verification: Use a professional Gerber viewer to display the design at 1:1 scale to simulate the actual effect.

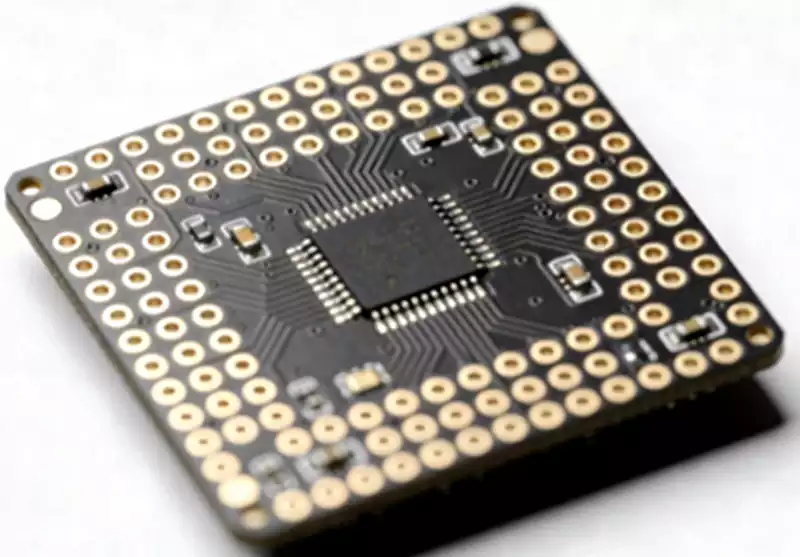

Physical comparison: print a reduced version of the PCB layout, direct placement of components, to check the suitability, especially for high pin-count packages such as QFP.

- Automated inspection: the power of DFM software

Intelligent analysis: DFM tools can automatically scan Gerber files to detect potential manufacturing challenges such as alignment spacing, pad size, etc. to improve manufacturability.

3.Design and Capacity Matching

Prior communication: Communicate with the manufacturer at the early stage of design to ensure that the design solution matches its production capacity and avoid design changes at a later stage.

Gap Issues

Reserve space: Ensure that there is sufficient electrical clearance between all pcb components, alignments and pads to prevent short circuits.

- Document format standardization

Format Uniformity: Adopt the widely accepted RS-274X format for export, or pre-confirm with the manufacturer for a compatible format version. - Drill file accuracy

Accuracy guidelines: Generate the correct drill file (e.g. .xln, .drl, .ile) to ensure accurate drill locations and dimensions.

Provide complete information

Additional drawings: Submit detailed fabrication drawings to supplement details not covered in the Gerber file,such as special cuts and board edge information.

- Other Key Points

Clear file naming: Use consistent and meaningful naming conventions for quick identification and sequencing by the manufacturer.

Complete board outline:Ensure that Gerber files contain a clear board outline to avoid production pauses.

Check document completeness: Avoid empty documents or missing important information by verifying the validity of each document individually.

Consistent design files: Ensure file versions are synchronized across all design phases to avoid production delays caused by inconsistent information.

Optimized CAD Settings: Properly configure CAD software to avoid unnecessary layer splitting or composite layer mapping errors.

Pad Handling: Adjust software settings to prioritize the generation of solid pads over vector pads to reduce manufacturing complexity.

Single Aperture List: Maintain a single and accurate list of apertures to simplify the manufacturing process and reduce confusion.

Importance of Gerber files in PCB manufacturing:

PCB designers need to create Gerber files using EDA tools that are compatible with the PCB manufacturer’s system.Mismatches in formats or tool versions can cause delays in the manufacturing process.The primary goal of Gerber files is to deliver reliable PCB orders within the expected time frame.

There are many benefits to using Gerber files in PCB manufacturing, including:

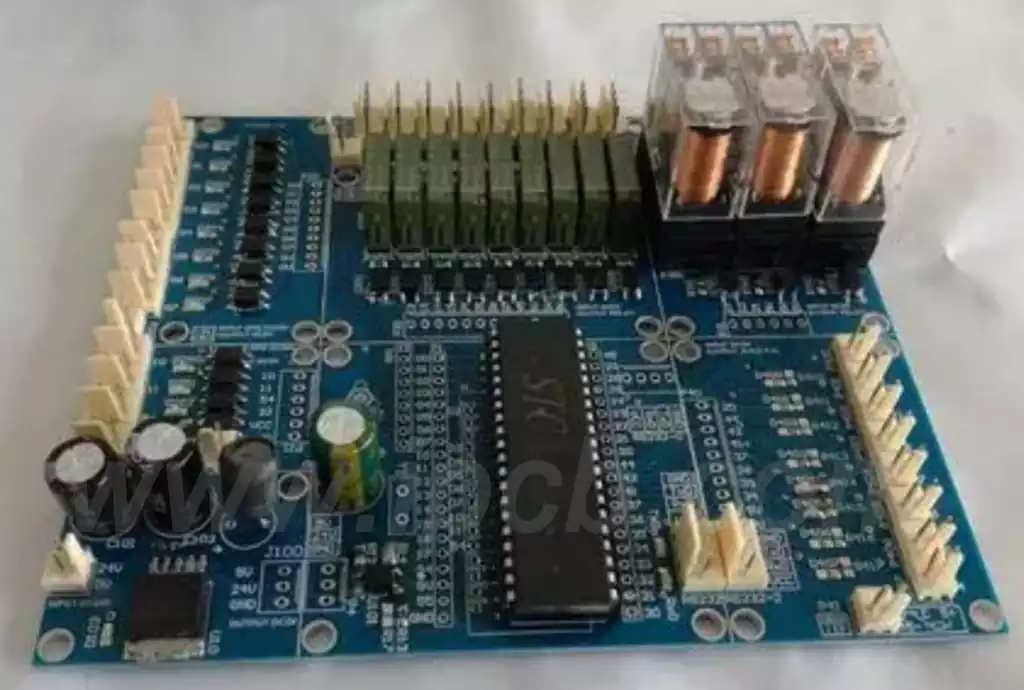

Gerber files provide intricately detailed designs that help PCB manufacturers build high-quality boards.Contract manufacturers can rely on these files to determine the accuracy of board dimensions, pad locations, alignment widths, and silkscreen legends. The accurate data provided by Gerber files significantly reduces the potential for manufacturing errors.

They are compatible with a wide range of CAM tools used by PCB manufacturers,and Gerber files can be easily exported from most EDA tools,ensuring a smooth transition from design to the production phase of the PCB development cycle.In addition,the flexibility of the data format allows contract manufacturers to employ different manufacturing and assembly techniques to support advanced technologies.

The standardized format of Gerber files is critical to establishing a flawless PCB manufacturing process. These files are easy to read and easy to use for design engineers, layout specialists, and assembly line technicians to reduce confusion and minimize rework throughout the manufacturing process.

Typically, contract manufacturers use Gerber files to perform design for manufacturability (DFM) checks and evaluate production yields. Similarly, these files are used to create fixtures for board inspection and test, contributing to quality control of PCB production.

Gerber files play a critical role in PCB manufacturing, not only as a bridge between design engineers and manufacturers, but also as the cornerstone of accurate, efficient, and reliable board production. With the continuous development of electronic technology, the importance of Gerber files will be more and more prominent, it will continue to play an irreplaceable role in the field of PCB manufacturing.