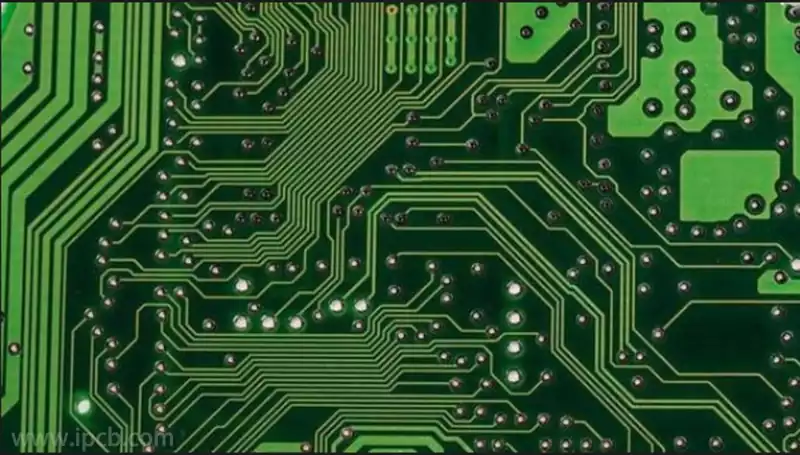

Heavy copper pcb is a printed circuit board (PCB) with a layer of copper foil bonded to its glass epoxy substrate, and when the thickness of the copper foil is greater than or equal to 2 ounces (i.e., ≥ 2oz), it is referred to as a PCB thick copper board.

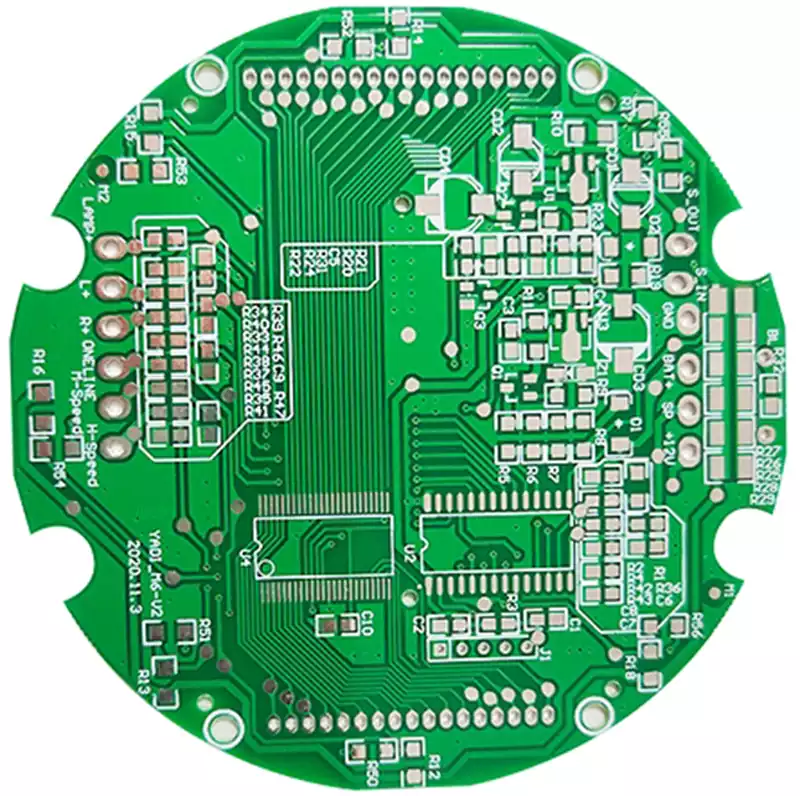

PCBs are widely used in power electronics, automotive electronics, communication equipment and aerospace with their outstanding performance. Its excellent heat dissipation, high current transfer capability and stability make it an indispensable cornerstone of the modern electronics industry. With the continuous innovation of technology and the expansion of application areas, it will continue to play a central role in promoting the development and innovation of electronic equipment.

Power electronics applications

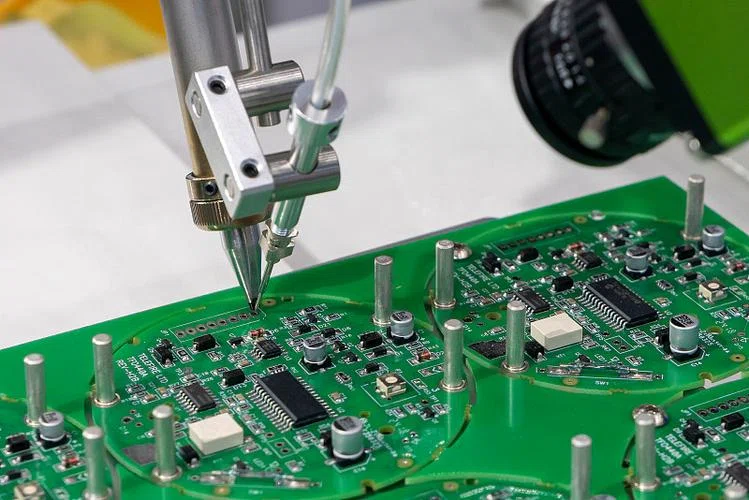

In the field of power electronics, PCBs play a pivotal role. In high-power devices such as power amplifiers, inverters and rectifiers, PCBs can significantly improve the heat dissipation effect to ensure stable operation under high loads. Their excellent heat dissipation characteristics make these boards widely used in various industrial power supplies, UPS and transformers. In power electronic equipment, PCB thick copper board can not only realize efficient heat dissipation, but also improve the current carrying capacity, reduce resistance and loss, thus improving the performance and reliability of the equipment. Therefore, PCB has become an indispensable key material for the power electronics industry.

Automotive electronics

With the rapid development of automotive electronics technology, heavy copper pcb board in the field of automotive electronics has also shown great potential for application. In the field of electric vehicles, intelligent driving and in-vehicle entertainment systems, PCB boards can provide stable and reliable electrical connections to meet the needs of high-power and high-frequency electronic devices. In addition, automotive electronic equipment is often required to operate in harsh operating environments, such as high temperature, high humidity and vibration, etc. PCB thick copper boards are ideal for the automotive electronics industry because of their high strength, high reliability and stable performance.

Communication Equipment Applications

In the field of communication equipment, such as base stations, satellite communications and wireless networks and other equipment, PCB thick copper also plays a key role. As communication equipment needs to carry high-power, high-frequency signals, PCB thick copper board’s low resistance, high thermal conductivity and stability make it the preferred material in this field.PCB thick copper board in communication equipment can not only enhance the stability and speed of signal transmission, but also reduce the size of the circuit board, improve the integration of equipment and performance. As a result, communication equipment manufacturers are increasingly adopting PCBs to meet the needs of high-power, high-frequency equipment.

Aerospace Applications

In the aerospace field, the requirements for electronic equipment are more stringent, the application of PCB thick copper boards is particularly important. Aerospace equipment needs to be both lightweight, highly reliable and high temperature resistant, and printed circuit board can fully meet these needs. In aerospace equipment, circuit boards can withstand high temperatures, high pressures and strong vibration and other harsh operating environments to ensure the normal operation of electronic equipment. At the same time, it can also meet the needs of aerospace equipment for high-power, high-frequency electronic devices, to protect the performance and safety of the equipment.

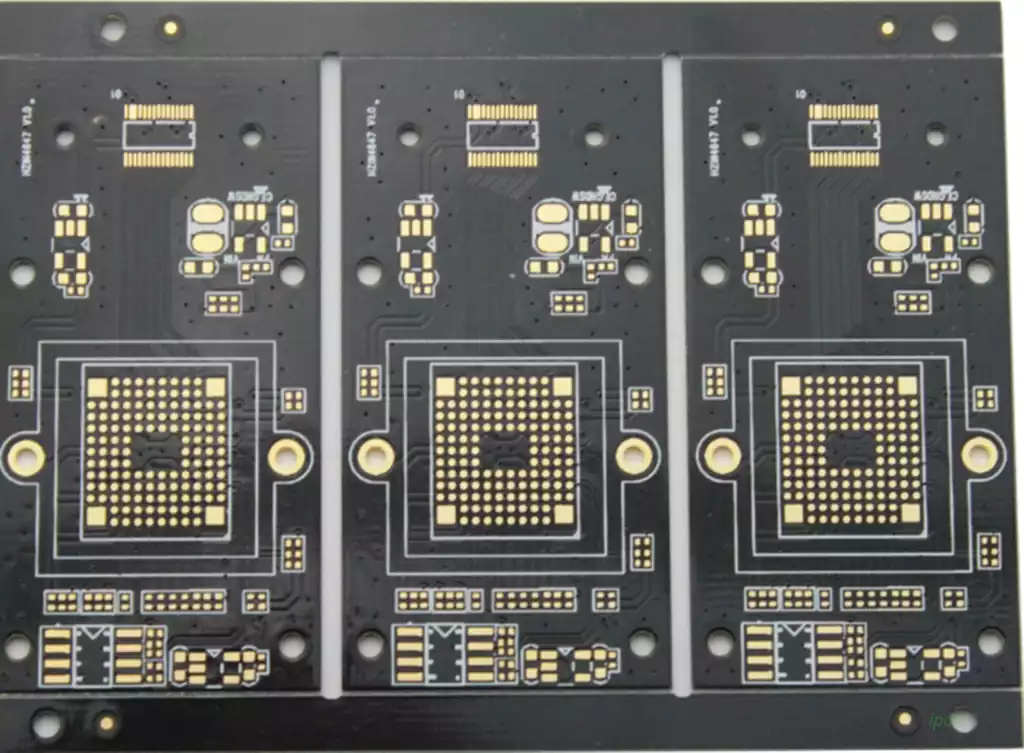

The price of thick copper plate is affected by a variety of factors, such as material quality, specifications, market conditions and so on. Generally speaking, the price of thick copper plate will gradually increase with the increase of plate thickness. At the same time, there are some differences in price between different manufacturers. Therefore, when choosing a supplier of thick copper plate, besides focusing on the price, you also need to consider other factors, such as product quality and after-sales service.

Selecting the most cost-effective and suitable supplier requires comprehensive consideration of a number of factors, such as focusing on the supplier’s reputation and word of mouth. Information can be obtained by checking relevant evaluations, consulting the opinions of other enterprises and so on. Secondly, it is important to understand the production capacity and delivery lead time of the supplier. This is very important for the production plan and schedule of the enterprise. In addition, it is also necessary to pay attention to the supplier’s after-sales service, including aspects such as product quality assurance and problem solving ability.

With its excellent heat dissipation effect, high current transfer capability and stability performance, heavy copper pcb plays an indispensable role in power electronics, automotive electronics, communication equipment and aerospace. Its strong application potential and broad market prospects make it a key force in promoting the development and innovation of the electronics industry. However, when choosing a thick copper plate supplier, companies need to consider price, product quality, after-sales service and many other factors to ensure that they find the most cost-effective and appropriate partner.