While it is true that there are some generally applicable basic processes in the PCB board industry, it is even more critical to carefully select and determine the appropriate production processes and equipment based on the thickness and material of the substrate, the precise standard of line width and spacing, the design architecture,the scale of production, and the specific requirements put forward by the customer.This characteristic also directly leads to a large difference in the cost of PCB production. But how much does a pcb board cost?

PCB board price components:

1.PCB material differences lead to significant price diversity

Take the common common double sided pcb board as an example, its board material variety,mainly including FR4 material (according to the brand,such as raw benefit,build the Tao,the national discipline,the price from high to low arrangement),a wide range of board thickness,from 0.2mm to 3.0mm ranging from copper thickness is also a variety of choices, from 0.5oz to 3oz each. These differences in board parameters lead to significant price differences at the base material level.In addition,the use of solder resist ink,ordinary thermosetting oil and photopolymerised green oil,there is also a certain price gap between.

- The diversity of surface treatment technology leads to price differences

Common surface treatment technologies include:OSP (for antioxidant treatment),leaded tin spraying,lead free tin spraying (in line with environmental requirements),gold plating,gold sinking and a variety of combination of processes. These technologies, with the technical complexity and environmental protection requirements,the price has gradually increased, showing a clear price gradient.

3.PCB production difficulty differences lead to price diversity

When the two pcb boards are distributed on the 1000 holes, if a board of holes larger than 0.2mm, and another smaller than 0.2mm,which will directly lead to differences in drilling costs.Similarly, if two boards have different line widths and spacings, all other things being equal – one with line widths and spacings greater than 4 mils and the other with less than 4 mils this will also result in a difference in production costs. In addition, some special designs, such as half-hole, buried blind holes, holes in the disc and the keypad printing carbon oil, etc.,these do not follow the conventional board process design, will also increase the additional production costs.

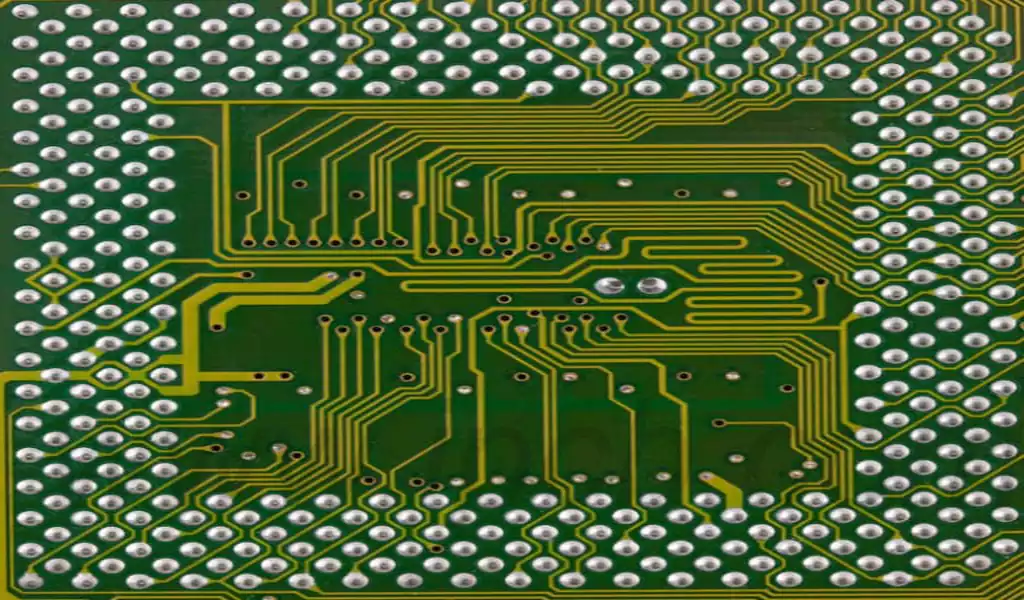

4.Differences in the thickness of copper foil lead to price diversity

Common thickness specifications for copper foil include: 18um (equivalent to 1/2OZ),35um (1OZ), 70um (2OZ), 105um (3OZ) and 140um (4OZ). In these specifications, the greater the thickness of the copper foil, the higher its price, showing a clear trend of increasing prices.

5.Customer’s quality acceptance criteria

Common quality acceptance criteria include: IPC2 grade, IPC3 grade, enterprise standard,military standard,etc.The higher the acceptance standard, the corresponding price will be increased.

6.Mould cost and test stand cost

(1) Mould cost:For prototype and small batch production, the pcb board factory usually adopts the way of drilling and milling the shape,so it will not charge extra milling cost.However,for mass production, in order to increase productivity and reduce production cost, it is usually necessary to make moulds for punching boards.The cost of a set of moulds is around $800.

(2) test costs: for the prototype,the pcb board factory generally use flying probe test,and most of the board factory has been exempted from this cost.But in mass production,in order to improve test efficiency and reduce production costs,the need to make test racks for testing.The general offer of the test frame is about 1200 yuan.

7.Differences in payment methods will also affect the price

The use of payment methods with a shorter arrival time (such as cash payment), you can usually enjoy a relatively low price.

8.Order size and delivery period

(1) Order size: Generally speaking, the smaller the order size, the higher the unit price will be. This is because even to produce a product, the board factory also needs to complete the preparation of engineering information, film output and all the necessary processes.

(2) Delivery time: If the factory is required to complete the production in a short period of time, this often leads to a rise in production costs.

(3) production information submitted to the PCB board factory must be detailed (including GERBER documents, the number of layers of the board, the use of boards, board thickness, the selected surface treatment process,ink colour,character colour and a clear description of all special requirements).

How much does a pcb board cost is the result of a comprehensive consideration of various factors, including materials, technology, production difficulty, customer demand, etc.,which together determine its final price. Therefore, it is not possible to simply give a fixed cost figure, but need to be accurately calculated according to the specific order.