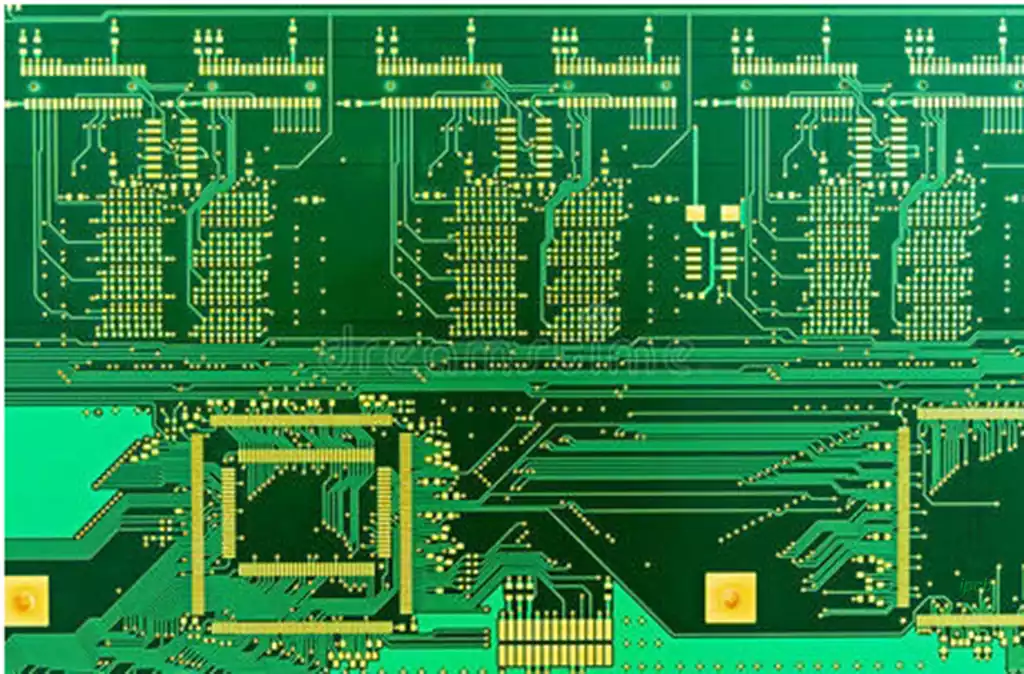

Flux is a chemical substance that removes oxides or other contaminants from the surface of the PCB, the solder itself, wets the metal surface to be soldered, protects the metal surface from re-oxidizing while soldering, reduces the surface tension of the molten solder, and facilitates the expansion and flow of the solder. However, once the soldering is complete, the presence of flux residues can become a potential problem. These residues may not only affect the electrical performance of the solder joint, but may also cause damage to other components on the board. Therefore, how to remove flux residues becomes a critical step in ensuring soldering quality.

Cleaning agent selection and steps

- Cleaning agent selection

Ethanol: ethanol is a commonly used cleaning agent, can effectively remove flux residues. However, ethanol is volatile and flammable and explosive, the use of safety issues should be noted.

Descaling agent: descaling agent is an efficient cleaning agent, can quickly remove welding residues. However, care should be taken when using it, do not let the descaling agent touch the skin to avoid causing irritation and injury.

Solvents: Chlorinated hydrocarbons, aromatic hydrocarbons and other solvents are also commonly used cleaning agents to quickly clean flux residues. However, these solvents are toxic and should be used safely.

How to clean flux residue

Use a specialized cleaner: Choose a cleaner specifically designed to remove flux residue. These usually contain powerful surfactants that effectively break down the flux residue.

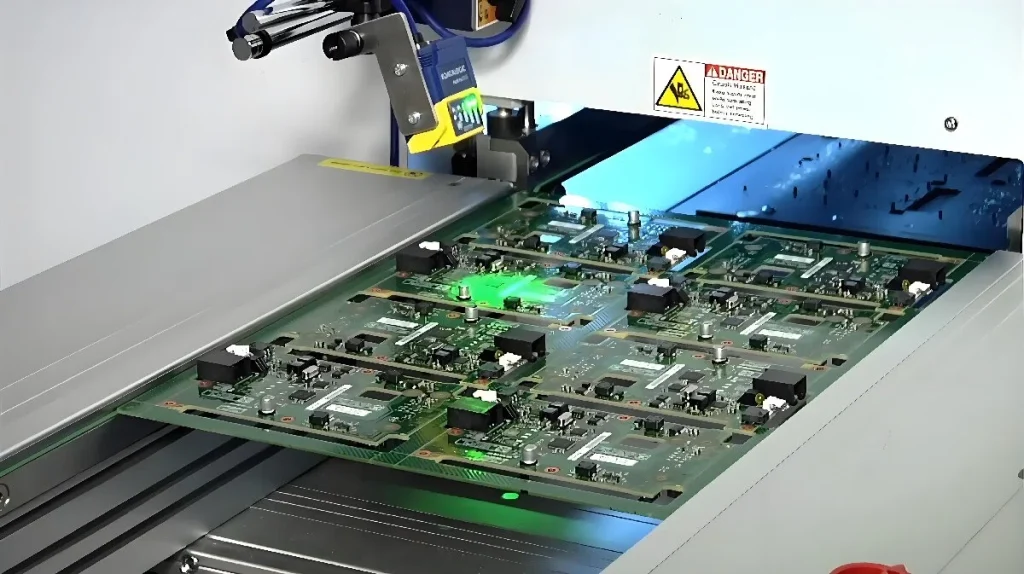

Ultrasonic Cleaning: Ultrasonic cleaning cleans the board surface by bursting tiny bubbles created by high-frequency vibrations. This method can penetrate deep into the tiny cracks and pores to improve the cleaning effect.

Steam Cleaning: Steam cleaning equipment is used to soften and easily remove flux residues through high temperature steam. Steam cleaning usually does not require the use of chemical cleaning agents.

Aerosol Cleaning: A method that employs a high-speed airflow and tiny droplets to form an aerosol that carries flux residues away from the board surface. This method is suitable for applications that are sensitive to cleaning agents.

Solvent Cleaning: The use of organic solvents, such as isopropyl alcohol, acetone or chlorinated hydrocarbons, can quickly dissolve flux residues. This is a fast and effective cleaning method, but careful consideration needs to be given to the environmental friendliness of the solvent and its impact on the board.

Dry Ice Cleaning: A new, efficient and environmentally friendly method that cools and removes flux residues by blasting dry ice particles at high speeds. This method does not require the use of liquid cleaning agents, and will not leave residues in the cleaning process, flexible particles on the electronic components without damage, effective protection of electronic components.

Precautions for flux residue cleaning

The following points need to be noted when cleaning:

Choose a suitable cleaning method to avoid damage to the components

Set appropriate cleaning parameters, such as temperature, time, etc.

Ensure the purity and quality of the cleaning solution

Observe the cleaning safety operation specification to avoid causing accidents.

In the electronics manufacturing industry, flux is a key factor to ensure the quality of welding, however, cleaning flux residue should not be ignored. Flux residue may not only affect the electrical performance of the product, but also cause long-term damage to the components on the circuit board. Therefore, it is crucial to choose the right cleaning method and strictly follow the cleaning safety practices.