Mounting holes refers to the holes used to install the circuit board in PCB. These holes are usually located in the four corners of the PCB or along the edge, and are used to fix the position of the circuit board in the device, as well as to connect to the mechanical bracket or fixture of the device. These holes usually have standardized sizes and spacings to accommodate different types of installation requirements.

When designing PCBs, it is crucial to consider the location and size of these holes, as they directly affect the installation method and stability of the circuit board. In the production and assembly process of PCB boards, installation mounting holes are an important link. Reasonable configuration and accurate installation of mounting holes can not only improve the assembly efficiency and accuracy of PCB boards, but also help to ensure the stability and reliability of circuit boards. This article will introduce in detail the steps and techniques for installing mounting holes on PCB boards to help readers better master this technology.

Definition and function of installation mounting holes

1) Definition of mounting holes

Installation mounting holes refer to holes arranged and processed on PCB boards for positioning components, semi-finished products or tooling clamping. The location and number of mounting holes are completed in the PCB board design stage, and drilling or punching is performed during processing.

2) The role of mounting holes

The main role of installing mounting holes is to achieve precise positioning between the PCB board and the required components or tooling, ensuring the accuracy and quality of assembly. They can provide reference points so that assemblers can quickly locate the components that need to be soldered or inserted, and reduce the risk of errors and damage.

Choose the right hole type

1) Round holes and square holes

Round holes are suitable for the installation of certain components that need to be rotated or adjusted, while square holes are suitable for the installation of components that need to be fixed. According to the specific component and tooling requirements, we can choose the appropriate type of mounting holes.

2) Single hole and multiple holes

Single holes are suitable for smaller and independent components, while multiple holes are suitable for large components or tooling. The combined distribution of multiple holes can provide higher installation accuracy and stability. 3) SMD and non-SMD components

For SMD components, it is more common and convenient to use edge mounting holes than metal mounting holes. Non-SMD components need to choose the appropriate positioning hole structure according to the specific size and tooling requirements.

Determine the location and number of mounting holes

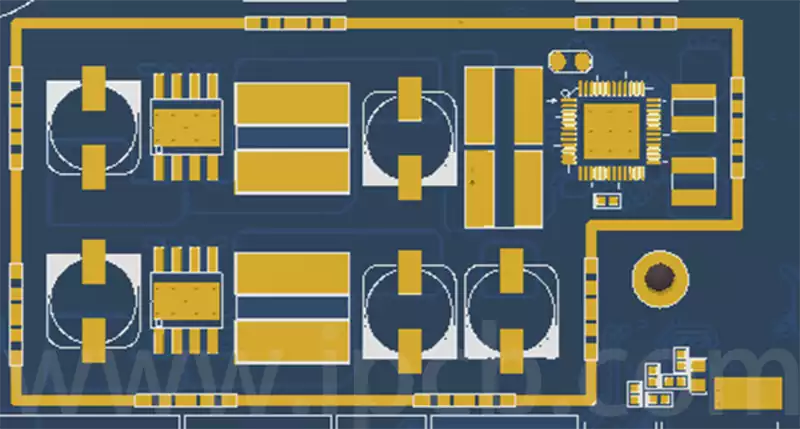

1) Layout of mounting holes

During the design stage of the PCB board, according to the requirements of the components and tooling, the design engineer needs to reasonably layout the location of the mounting holes. Generally speaking, the locating holes should be evenly distributed, covering the entire surface of the PCB board to provide multiple leads and base connections.

2) Calculate the number and spacing of holes

For each component or tooling, the number and spacing of the installation locating holes need to be determined. Usually, each component requires at least 4 locating holes to ensure accurate and stable connection. According to the size and requirements of the PCB board, the reasonable number and spacing of locating holes can be calculated and reasonably distributed.

Processing and setting of installation locating holes

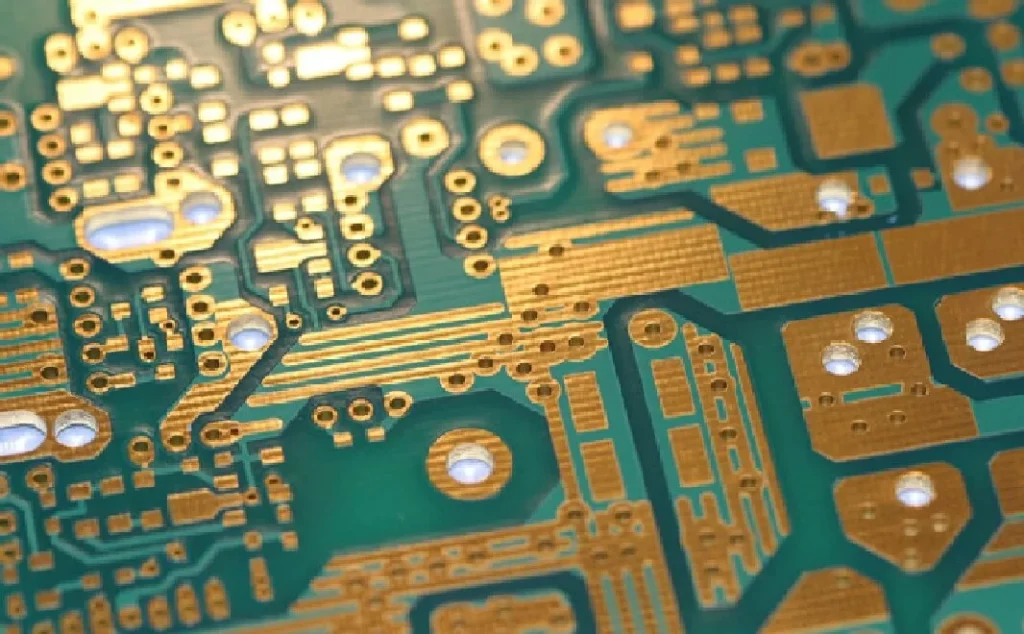

1) PCB board processing

For the processing of PCB boards, the locating holes can be processed to the specified position according to the design requirements with the help of drilling or punching technology. According to the number and size of the holes, suitable processing equipment and processes can be selected.

2) Process settings and specifications

During the processing of locating holes, the process settings and specifications need to be strictly followed. According to the pre-designed position and size, the equipment should be adjusted strictly as required to ensure the accuracy and quality of processing.

Use and maintenance of locating holes

1) Use locating pins for positioning

In the actual assembly process, workers use locating holes to match the corresponding locating pins for positioning. The position of the installation locating hole must be consistent with the position of the locating pin to ensure the correct positioning of the component.

2) Maintenance of mounting holes

In order to ensure the stability and reliability of the PCB board, the installation mounting holes need to be checked and maintained regularly. Once the hole mouth is found to be worn or deformed, it should be replaced or repaired in time. At the same time, collision and extrusion should be avoided during storage and transportation.

The installation mounting holes of the PCB board are an important part of ensuring assembly accuracy and quality. Correct selection, layout and processing of installation mounting holes can improve assembly efficiency and ensure stable connection between components and PCB boards.

Through the introduction of this article, I believe that you have a comprehensive understanding of the steps and techniques of installing mounting holes on PCB boards, and can better apply them in practice.