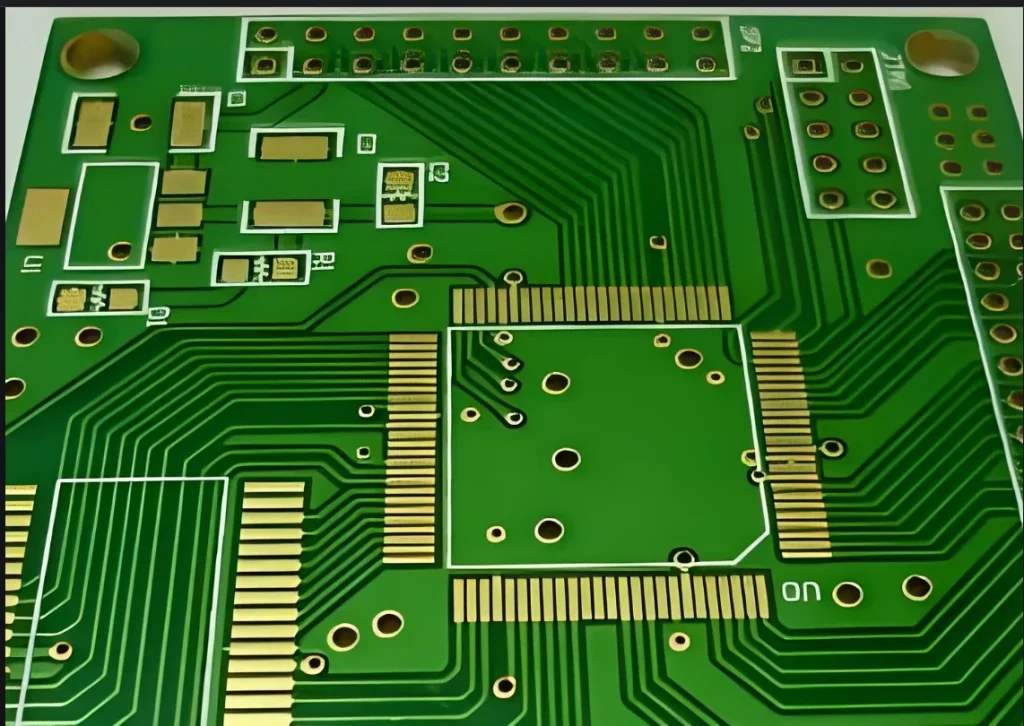

Ceramic printed circuit board, which is manufactured on the basis of ceramic materials such as high-purity alumina ceramics, have become one of the highlights of modern electronics manufacturing. Compared to conventional plexiglass fiber circuit boards, ceramic circuit boards exhibit higher mechanical strength, excellent temperature resistance and thermal conductivity, as well as outstanding dimensional and chemical stability.

Advantages:

The first thing that must be mentioned is their outstanding high-temperature efficiency. Ceramic circuit boards are able to operate stably at temperatures of up to 1,000°C, far exceeding the 100-200°C range that conventional PCBs can withstand. In addition, its thermal conductivity is usually 3-5 times that of conventional PCBs, for example, the thermal conductivity of alumina ceramics is as high as 30W/mK, which is much better than that of glass fiber boards at 0.2W/mK.

The dielectric constant of ceramic pcb is also a major advantage, usually between 5-10, compared to the 4-6 range of traditional PCB, providing a better quality of signal transmission. At the same time, due to the characteristics of ceramic materials, they have higher strength and hardness. Aluminum oxide ceramics are more than 10 times stronger and more than twice as hard as ordinary glass, which makes it more durable.

Corrosion resistance is also a major feature of ceramic circuit boards, it can be in the strong acid and alkali environment stable operation, while the traditional PCB is prone to corrosion. In addition, it can also be made into ultra-thin, ultra-small size, to achieve a higher degree of integration and smaller size, and compared to traditional PCB, ceramic circuit boards are more lightweight.

Ceramic circuit boards are widely used in many fields due to their unique properties. In the aerospace industry, they are able to withstand extreme temperatures and high radiation environments, making them ideal for equipment such as satellites, missiles and airplanes. In the military field, they are also favored for their resistance to high temperature, high pressure and high radiation. In the medical device field, the antimicrobial, high-temperature and corrosion-resistant properties of it makes them key components in medical devices such as pacemakers and prostheses. In addition, they are widely used in electronic products, new energy sources and other industrial fields.

With their unique material properties, the pcb boards not only exhibit excellent resistance to abrasion, oxidation, and high temperatures, but also provide a larger capacity to accommodate more components under the same surface area. This makes it ideal for the high-precision equipment industry, promoting the continuous innovation and development of electronic manufacturing technology.

In summary, Ceramic printed circuit boards, as a high-performance material, are leading a new round of innovation in the electronics manufacturing industry with their excellent performance and wide range of applications.