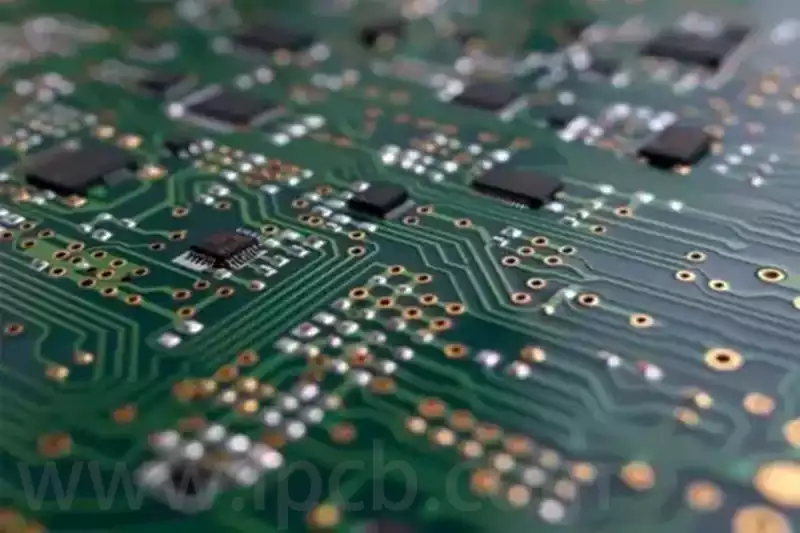

Laminate PCB board is a composite material consisting of multiple layers of thin plates stacked on top of each other with good electrical conductivity, insulation, and mechanical strength. In the manufacturing process of printed circuit boards, laminate is used as a substrate to carry the functions of wiring and soldering electronic components. Its quality directly affects the performance and reliability of the PCB.

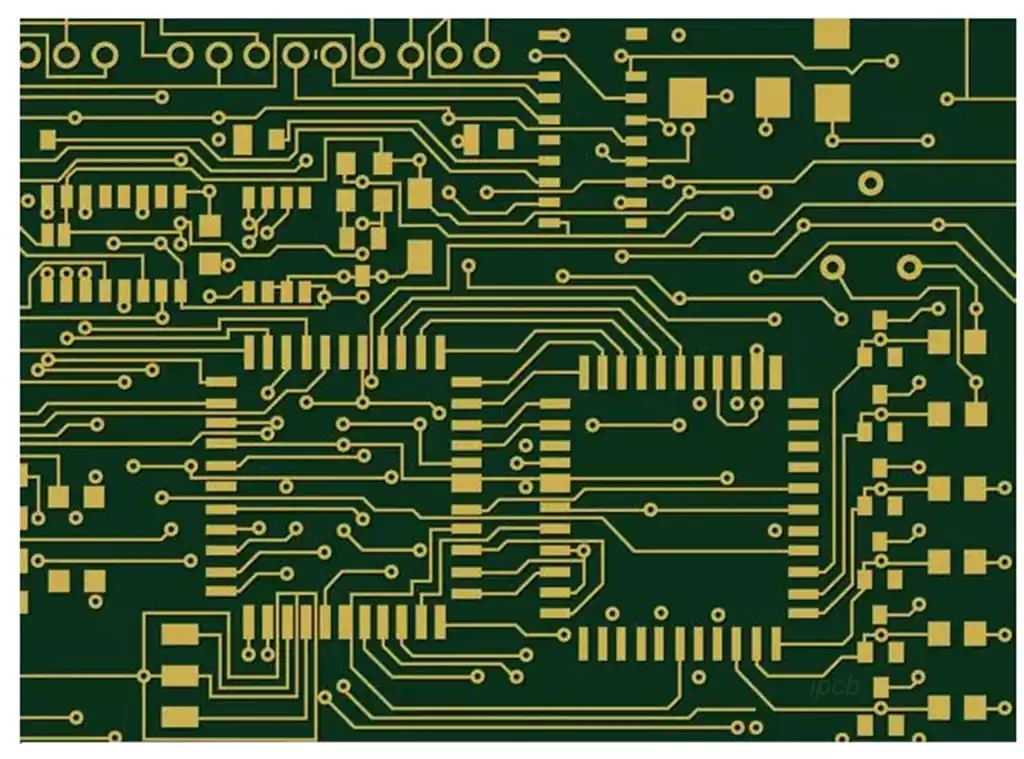

Typically, PCB substrate has four layers: a silkscreen layer, a soldermask layer, a copper layer, and a substrate. Therefore, these layers must be combined together to become the functional structure of the PCB. Therefore, the purpose of a PCB laminate is to hold the PCB layers of a printed circuit board together. Laminates are usually copper-clad and often consist of resin sheets.

Classification:

Depending on the material composition and application, they can be categorized as follows:

Phenolic resin laminates: characterized by heat resistance, corrosion resistance, and high mechanical strength, commonly used in the production of electronic parts, insulating materials, and mechanical parts.

Epoxy resin laminate: good abrasion resistance, corrosion resistance, high strength, and high stability, commonly used in the production of high-strength parts and highly durable molds.

Fiberglass laminate: with high strength and stiffness, it is one of the most widely used laminate PCB board materials, commonly used in the production of ship hulls, aircraft parts, construction materials, etc…

Carbon fiber laminate: with excellent mechanical properties and stiffness, lightweight and high-temperature resistance, corrosion resistance, etc., commonly used in the aerospace field, racing car bodies, and other high-end fields.

According to the production process and form, it can be divided into the following types:

Resistant laminates: produced by bonding laminate layers to a substrate under high pressure, they are considered to be one of the durable laminates and are therefore ideal for horizontal surfaces, including floors and countertops.

Low-Pressure Laminate: In low-pressure laminates, the laminate layers are bonded to the substrate under low pressure. These laminates are relatively cheaper than rebates.

Laminate pcb is a composite material consisting of multiple layers of thin sheets stacked on top of each other, providing good electrical conductivity, insulation, and mechanical strength. Its properties include:

High specific strength and modulus: with high specific strength and modulus, it can withstand large loads and is not easily deformed.

Light specific gravity: Smaller specific gravity reduces the weight of the overall structure, which is conducive to lightweight design.

Easy molding and manufacturing: It can be processed by hot pressing or adhesive and other processes, making it easy to produce parts of various shapes and sizes.

Excellent corrosion resistance: good corrosion resistance, able to withstand a variety of chemical substances.

Ideal Thermal Expansion Characteristics and Economic Efficiency: With a low coefficient of thermal expansion, it is possible to maintain dimensional stability during temperature changes. At the same time, its relatively low manufacturing cost is conducive to economic efficiency.

In addition, phenolic resin laminates are also characterized by high heat resistance, corrosion resistance, and mechanical strength, and are commonly used for making electronic parts, insulating materials, and mechanical parts; the epoxy resin is characterized by good abrasion resistance, strong corrosion resistance, and high strength, and is commonly used for making high-strength parts and highly durable molds; fiberglass, with its advantages of high strength and high stiffness, is one of the most widely-used laminating materials, and is commonly used for The production of ship hulls, aircraft parts, building materials, etc.; carbon fiber has excellent mechanical properties and stiffness, lightweight and high-temperature resistance, corrosion resistance, and other characteristics, commonly used in aerospace, racing car body and other high-end areas.

When selecting laminates, the following factors need to be considered:

Performance requirements: Select the right material according to the application scenario and performance requirements. For example, laminates used in high-temperature, high-pressure, or corrosive environments need to have characteristics such as high-temperature resistance and corrosion resistance.

Size and shape: According to the actual needs, select the appropriate size and shape to ensure that it can meet the requirements of use.

Processing: Different laminate materials have different processing requirements, such as hot pressing, adhesives and so on. Choosing the right material can ensure the smoothness of the processing.

Cost: The price of laminates varies depending on the material, specification, and quality. When selecting laminates, it is necessary to consider the cost and performance requirements to choose the most cost-effective solution.

As the core material of the electronics industry, laminate PCB board plays a pivotal role in promoting the development of the electronics industry. In the face of future market challenges and opportunities, the laminate industry needs to continue to innovate and improve to meet the changing market demand.