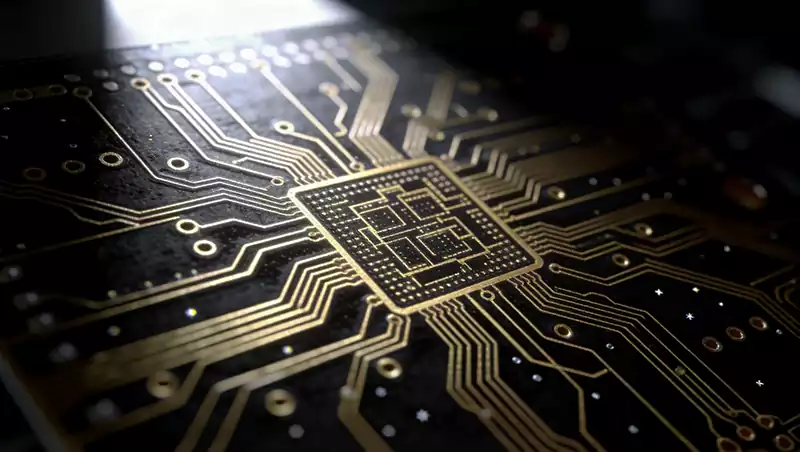

In the realm of modern electronics, the demand for efficient, compact, and versatile lighting solutions has led to the widespread adoption of LED technology. At the heart of many LED applications lies the PCB (Printed Circuit Board), a crucial component that not only supports the LEDs but also ensures their optimal performance. Among the various types of PCBs, the LED round PCB board has gained significant attention due to its unique design and application benefits. In this article, we will explore what an LED round PCB board is, its advantages, applications, and key considerations for design and manufacturing.

What is an LED Round PCB Board?

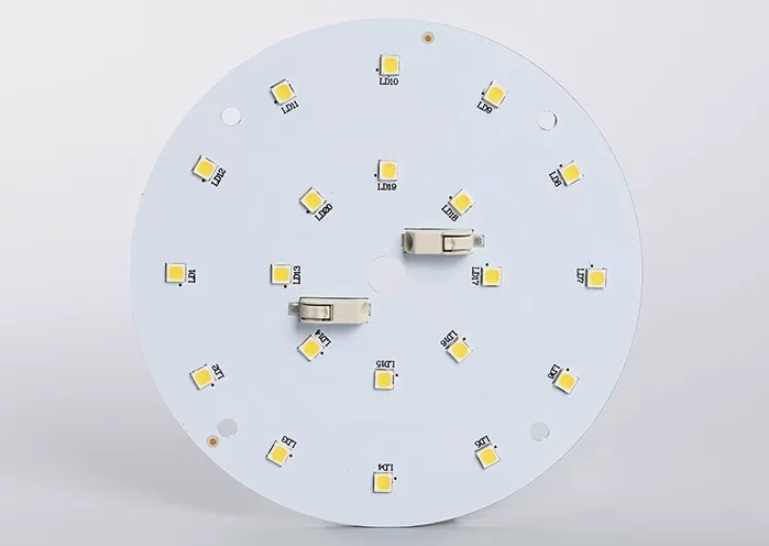

An LED round PCB board is a circular printed circuit board specifically designed to house and support LEDs (Light Emitting Diodes). Unlike traditional rectangular or square PCBs, the round shape is particularly useful in applications where space constraints and aesthetic considerations play a critical role. The board provides the mechanical support for the LEDs and serves as a platform for electrical connections, enabling the LEDs to function properly within a circuit.

Advantages of LED Round PCB Boards

- Space Efficiency: The round shape of these PCBs makes them ideal for applications where space is limited, such as in circular lighting fixtures, downlights, and automotive lighting systems. The circular design allows for more efficient use of available space, especially in devices where round or cylindrical shapes are preferred.

- Aesthetic Appeal: The round PCB’s shape often aligns better with the design requirements of modern lighting fixtures, offering a more aesthetically pleasing solution compared to traditional rectangular boards. This is particularly important in consumer electronics, where the look and feel of a product can significantly influence its market success.

- Improved Thermal Management: LEDs generate heat during operation, and managing this heat is crucial to ensure the longevity and performance of the LEDs. Round PCB boards, particularly those made from materials like aluminum, offer superior thermal management. The circular shape allows for better heat dissipation, reducing the risk of thermal hotspots that could damage the LEDs.

- Enhanced Durability: Many LED round PCBs are designed with robust materials and layouts that enhance their durability. This makes them suitable for applications in harsh environments, such as outdoor lighting and automotive applications, where exposure to moisture, dust, and vibrations is common.

- Customizability: LED round PCB boards can be customized to fit specific applications, with options for different sizes, LED arrangements, and materials. This flexibility allows designers to create tailored solutions that meet the exact needs of their projects.

Applications of LED Round PCB Boards

The versatility of LED round PCB boards makes them suitable for a wide range of applications across various industries:

- Lighting Fixtures: LED round PCBs are commonly used in various lighting fixtures, including downlights, spotlights, and ceiling lights. The circular shape of the board aligns well with the design of these fixtures, providing uniform light distribution and enhancing the overall aesthetic appeal.

- Automotive Lighting: In the automotive industry, LED round PCB boards are used in headlights, tail lights, and interior lighting systems. Their durability and efficient thermal management make them ideal for automotive applications, where reliability and performance are paramount.

- Wearable Devices: Wearable technology, such as smartwatches and fitness trackers, often incorporates LED round PCBs due to their compact size and ability to fit within the curved contours of the devices. These PCBs support LEDs that provide notifications, display information, and enhance the user experience.

- Displays and Signage: LED round PCBs are also used in digital displays and signage, where they help create bright, energy-efficient displays with minimal power consumption. The round shape of the PCB allows for creative designs, such as circular displays or logos.

- Medical Devices: In the medical field, LED round PCBs are used in diagnostic equipment, surgical lighting, and other medical devices that require precise and reliable illumination. The boards’ ability to manage heat effectively is especially important in medical applications, where equipment reliability is critical.

Key Considerations for Designing and Manufacturing LED Round PCB Boards

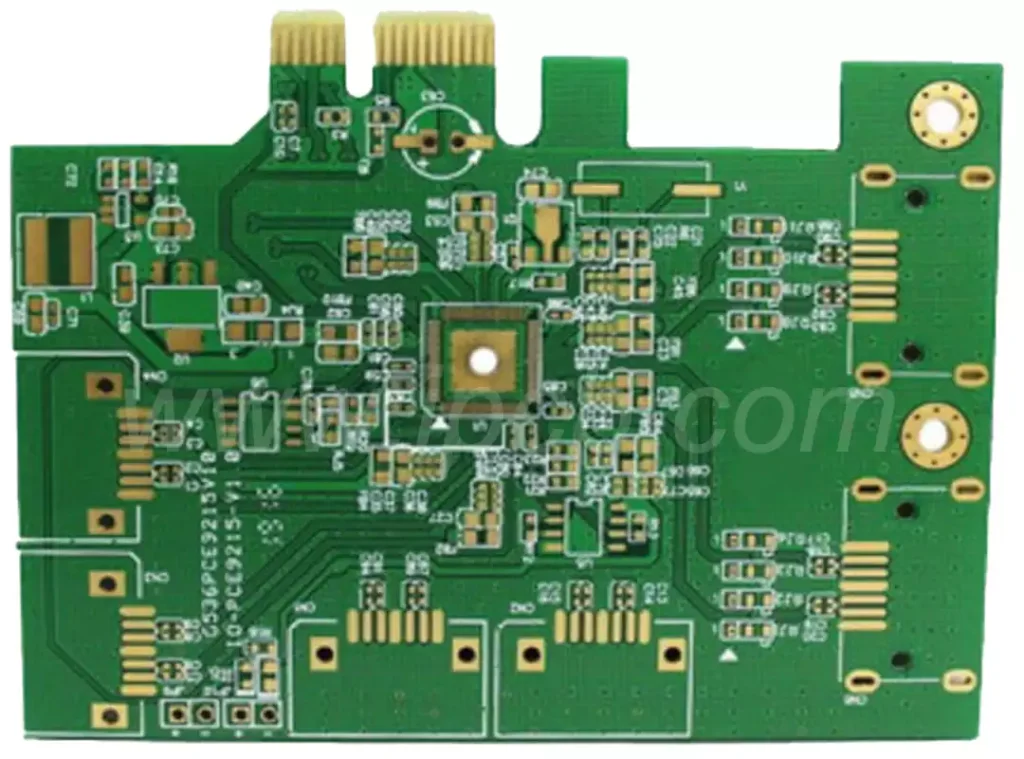

Designing and manufacturing LED round PCB boards requires careful attention to several factors to ensure optimal performance and reliability:

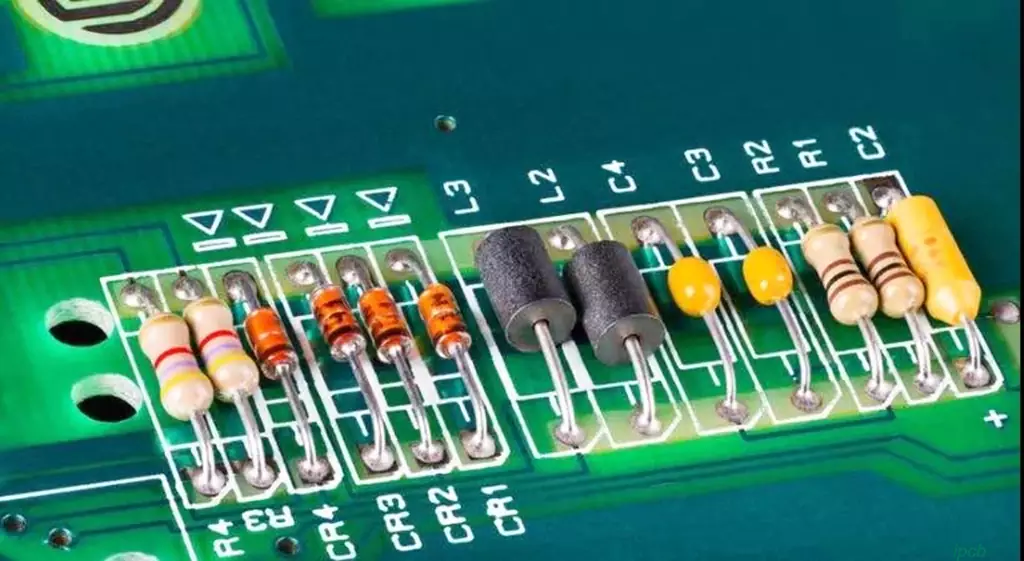

- Material Selection: The choice of materials plays a critical role in the performance of LED round PCB boards. Common materials include FR-4 (a composite material made of fiberglass and epoxy resin) for general applications and aluminum for applications requiring enhanced thermal management. The material must be chosen based on the specific requirements of the application, such as thermal conductivity, electrical performance, and mechanical strength.

- Thermal Management: Effective thermal management is essential to prevent overheating of the LEDs and extend their lifespan. This can be achieved by using materials with high thermal conductivity, designing appropriate thermal vias, and incorporating heat sinks or thermal pads into the PCB design.

- LED Placement and Density: The placement and density of LEDs on the PCB board significantly impact the performance of the lighting solution. Designers must carefully consider the spacing between LEDs to ensure uniform light distribution while avoiding excessive heat concentration. The arrangement of LEDs should also align with the intended application, whether it’s for focused lighting or wide-area illumination.

- Circuit Design: The circuit design of the LED round PCB board must be optimized to ensure efficient power delivery to the LEDs. This includes selecting the appropriate trace widths, considering voltage drops, and ensuring proper grounding. In some cases, designers may need to incorporate current-limiting resistors or drivers to regulate the LED current and prevent damage.

- Manufacturing Tolerances: During manufacturing, maintaining tight tolerances is crucial to ensure that the LEDs are positioned correctly and that the PCB performs as intended. This requires precision in drilling, routing, and solder mask application. Manufacturers must also consider the potential for warping or other deformations that could impact the PCB’s performance, especially in high-temperature environments.

- Testing and Quality Control: Rigorous testing and quality control measures are essential to ensure the reliability and performance of LED round PCB boards. This includes electrical testing to verify circuit functionality, thermal testing to assess heat dissipation, and visual inspection to identify any defects or inconsistencies.

LED round PCB boards represent a vital component in modern electronic devices, particularly in applications requiring efficient, compact, and aesthetically pleasing lighting solutions. Their unique design offers numerous advantages, including space efficiency, improved thermal management, and enhanced durability. As technology continues to advance, the demand for LED round PCBs is expected to grow, driven by the increasing need for innovative lighting solutions across various industries.

LED round PCB boards will continue to play a crucial role in shaping the future of electronic design, whether used in automotive lighting, wearable devices, or medical equipment. By understanding their benefits and the key considerations in their design and manufacturing, engineers and designers can create high-performance, reliable products that meet the evolving demands of today’s market.