The LG Microwave PCB Board is a key component in a microwave oven that is responsible for controlling the functions and operating status of the microwave oven. Often referred to as the control circuit board, this circuit board is capable of processing input signals and executing preset programs.

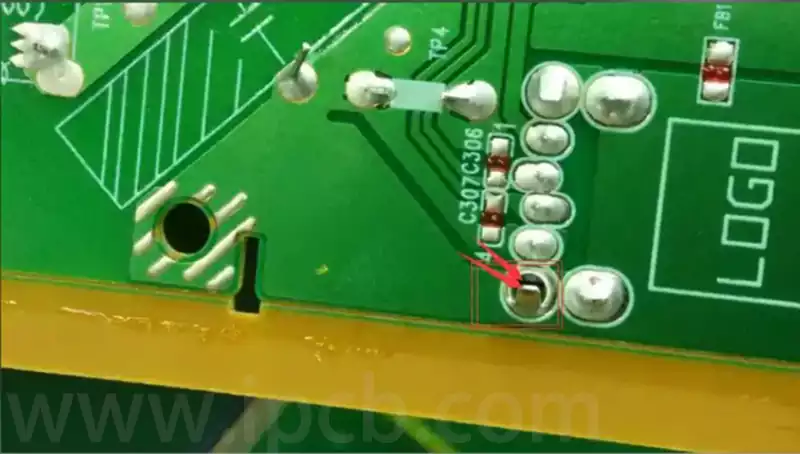

LG microwave circuit boards usually contain control circuits, power modules and input/output interfaces. The control circuit board is the core of the microwave oven to realize various functions, including temperature control, timer and power regulation, etc. LG microwave ovens have relatively complex secondary circuits that are capable of handling many different programs and input signals. The main components on the circuit board include thyristors, transformers and control buttons. Among them, the thyristor is used to regulate the on/off of the current to achieve precise control of the heating power. The transformer is responsible for converting the supply voltage into a voltage suitable for microwave ovens to ensure a safe and efficient circuit. In addition, key inputs are used for user interaction with the device, making operation more flexible and user-friendly.

Functions of LG Microwave PCB Board

- Control Signal Input

Instead of triggering the thyristor directly,the key input signal on the LG Microwave PCB Board feeds the signal into the control circuit,which in turn controls the operation of the microwave oven.This design allows the board to handle a wide range of complex operating commands and automatically adjusts the microwave output according to the user’s settings. - Functional Versatility

The complexity of the control circuit board allows the LG microwave oven to perform a variety of programs.For example,it supports different heating modes, timer settings, and pre-processing programs for specific foods.These diverse functions allow users to make flexible choices based on different cooking needs. - Heating Control

The secondary circuit on the circuit board is the key part to realize the heating function,which enables the food to be heated evenly by precisely controlling the emission of microwaves.This control mechanism ensures the stability and safety of the microwave oven at different power settings,preventing overheating or under-heating problems. - Safety Protection Mechanism

LG microwave pcb board also incorporates a variety of safety protection features. For example,the microwave oven will not start when the door is open to prevent the user from being exposed to dangerous microwave energy.This design is intended to safeguard the user and reduce potential risks during use. - Maintenance and Cleaning

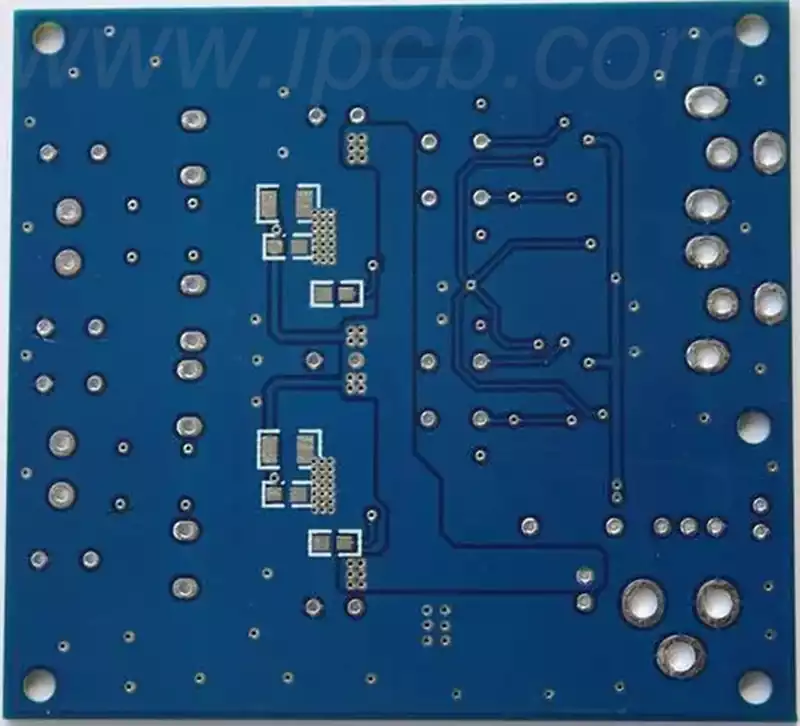

Regular cleaning is necessary to keep the circuit board functioning properly. Users should regularly remove food residue and dust from the pcb substrate to ensure the accuracy of signaling and long life of the circuit.A well-maintained circuit board not only improves the performance of the microwave oven,but also extends the life of the unit.

Considerations needed when designing LG microwave pcb board:

1.Material Selection

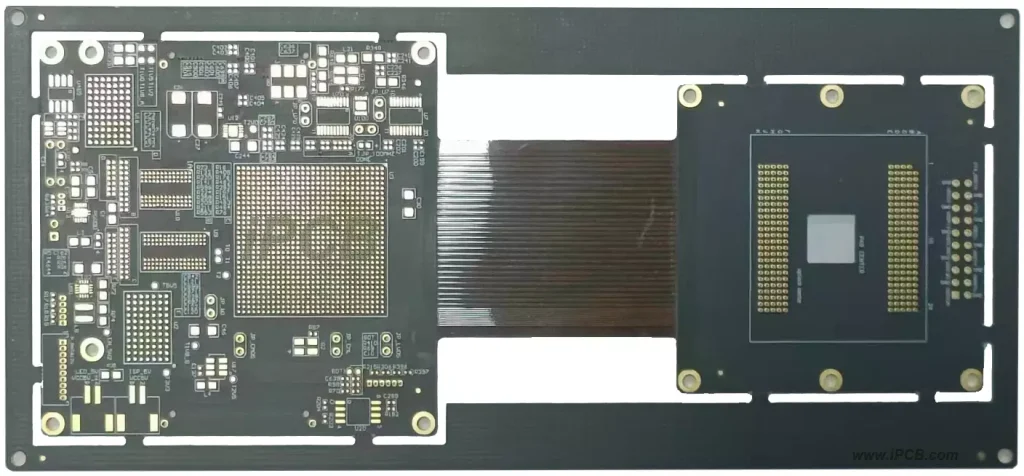

The choice of material for the circuit board is critical to its performance.Materials with the appropriate dielectric constant (Dk), dielectric loss and coefficient of thermal expansion (CTE) should be selected to ensure that the board can operate stably at a specific frequency. High-frequency materials such as the ROGERS series of plates are often used in microwave circuit design to improve the efficiency and reliability of signal transmission.

2.Layout and Wiring

The layout and routing design of electronic components should be carefully considered in the design. Components should be as close as possible to reduce signal delay and reduce inductance. For high-frequency signals, sharp turns should be avoided and 45-degree bends or arcs should be selected to reduce signal reflection and impedance mismatch.

3.Thermal Management

The heat generated by high-frequency components in microwave circuit boards needs to be managed effectively to prevent performance degradation and failure. The design should include materials with good heat conduction, heat sinks and holes to ensure that heat can be effectively dissipated.

4.Electromagnetic compatibility (EMC)

Electromagnetic compatibility also needs to be considered during the design process to minimize electromagnetic interference between equipment. Appropriate shielding and layout measures should be taken, such as the use of grounding layers and isolation of different signal channels to prevent signal crosstalk and ensure normal functional operation.

5.Signal Integrity

Signal integrity is critical to the performance of microwave boards. Issues such as signal distortion, timing errors and crosstalk should be considered in the design to ensure that the signal quality is maintained throughout the transmission process. In addition, proper impedance matching should be achieved to minimize reflections and losses.

6.Reliability Testing

Upon completion of the design, adequate testing must be performed to verify the functionality and stability of the board. This includes both functional and environmental stress tests to ensure that the board will operate reliably for long periods of time under predetermined operating conditions.

Effective implementation of thermal management is a key factor in ensuring stable performance of microwave boards:

1.The importance of material selection for thermal management

In microwave circuit design, the choice of PCB material has a significant impact on overall thermal management. The right material can improve the power handling capability of the circuit and effectively control the temperature rise to prevent failures due to overheating. The thermal conductivity, coefficient of thermal expansion, and power carrying capacity of the material are all key considerations that need to be carefully selected during the design process.

2.Thermal Structure Design

A good thermal structure helps to reduce the operating temperature of the board and keep its performance stable.In the design,the use of heat sinks, chassis design and air circulation with the external environment are the basic elements. Reasonable configuration of these heat dissipation components can effectively emit heat in different power and operating conditions to prevent heat concentration.

3.Environmental management and working conditions

External ambient temperature also has a significant impact on the thermal management of the PCB. In a high-temperature environment,the thermal efficiency of microwave circuit boards may be reduced, so it is necessary to provide appropriate cooling measures.Methods such as using fans or gas-liquid heat exchangers can be considered to optimize the cooling effect and ensure that the circuit remains stable in high-temperature areas or extreme conditions.

4.Application of heat flow modeling

The implementation of effective thermal management also requires the establishment of an accurate heat flow model to analyze the distribution of heat sources and heat transfer path. Through simulation and testing,potential thermal problems can be predicted in advance,and improvements can be made at the design stage to ensure the reliability and long-term stability of the circuit function.

5.Regular monitoring and maintenance

During the operation of microwave circuit boards, it is crucial to regularly monitor their operating temperatures and the performance of the thermal management system. This helps to identify problems and take appropriate maintenance measures in a timely manner to ensure that the equipment operates at its optimum condition and to prevent performance degradation due to excessive temperatures.

LG microwave pcb board is an important part of the microwave oven,responsible for realizing a number of core functions to ensure the efficiency and safety of the equipment. Through proper material selection, layout design,thermal management and EMC considerations,designers are able to optimize board performance for signal integrity and reliability. The need for regular monitoring and maintenance should not be overlooked,as this will help extend the life of the microwave oven and keep it running efficiently.