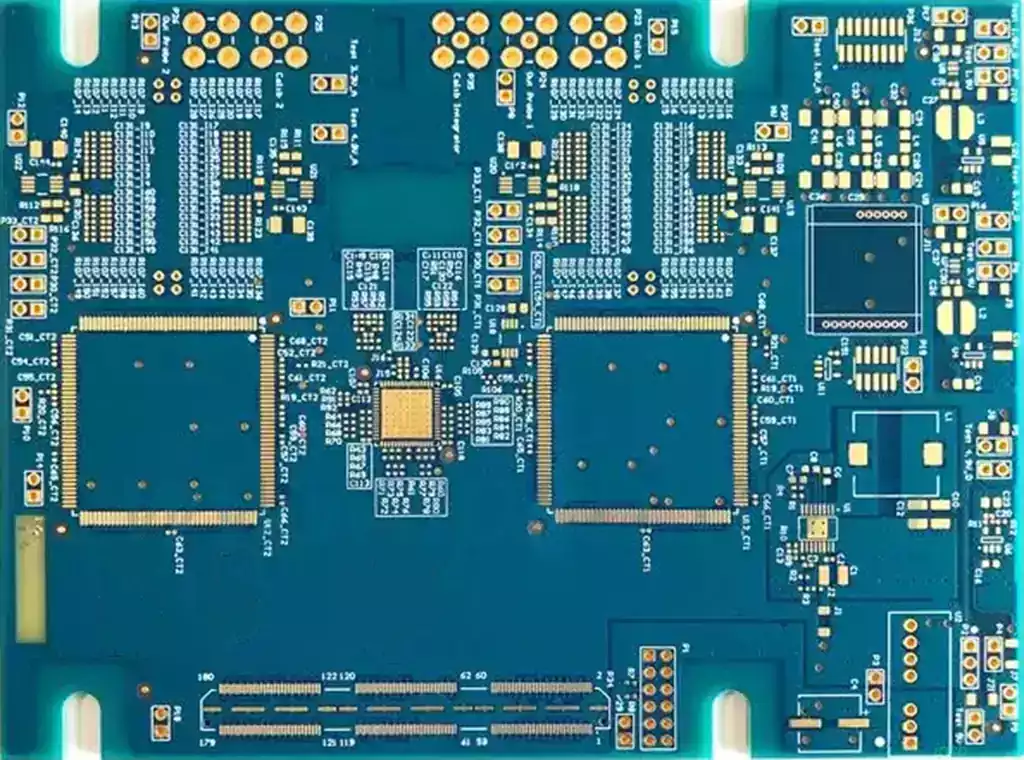

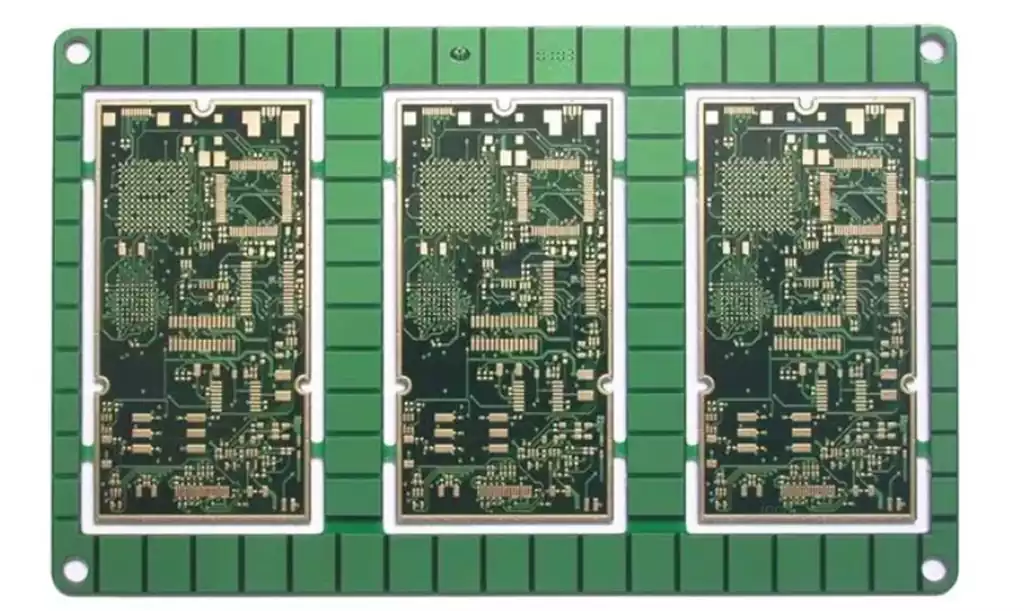

The main PCB board is the core component of electronic equipment, mainly used to carry and connect various electronic components, signal transmission, power distribution, and other functions.

Through precise line design, the main PCB board effectively connects each component to form a whole that works together. Its role in electronic equipment is crucial, not only to improve the reliability and stability of the equipment but also to simplify the production and maintenance process. It is generally made of composite epoxy resin or glass fiber and other materials, with high insulation, high-temperature resistance, corrosion resistance, and other characteristics. At the same time, the line design has been strictly calculated and optimized, which can ensure the accuracy and stability of signal transmission.In Electronic equipment, it is widely used in computers, communication equipment, aerospace, and other fields, and is an indispensable and important part of the modern electronic industry.

Advantages of the main printed circuit board:

High integration: it can realize the high integration of electronic components, reduce the volume and weight of electronic equipment, easy to carry and use.

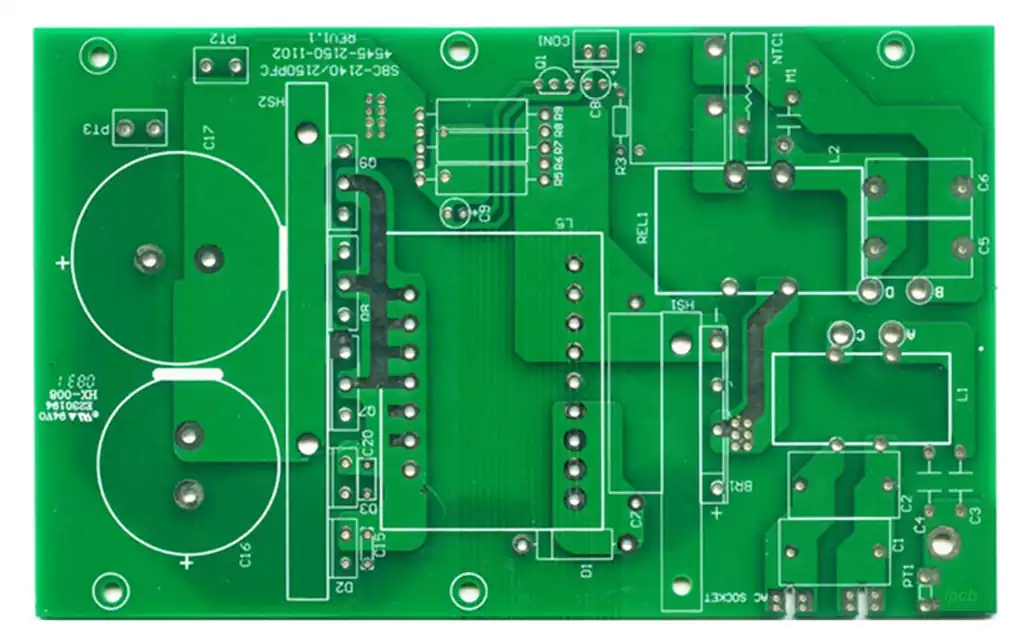

High reliability: the use of specialized manufacturing processes, with good electrical and mechanical properties, can ensure the stability and reliability of the circuit and reduce the occurrence of failures.

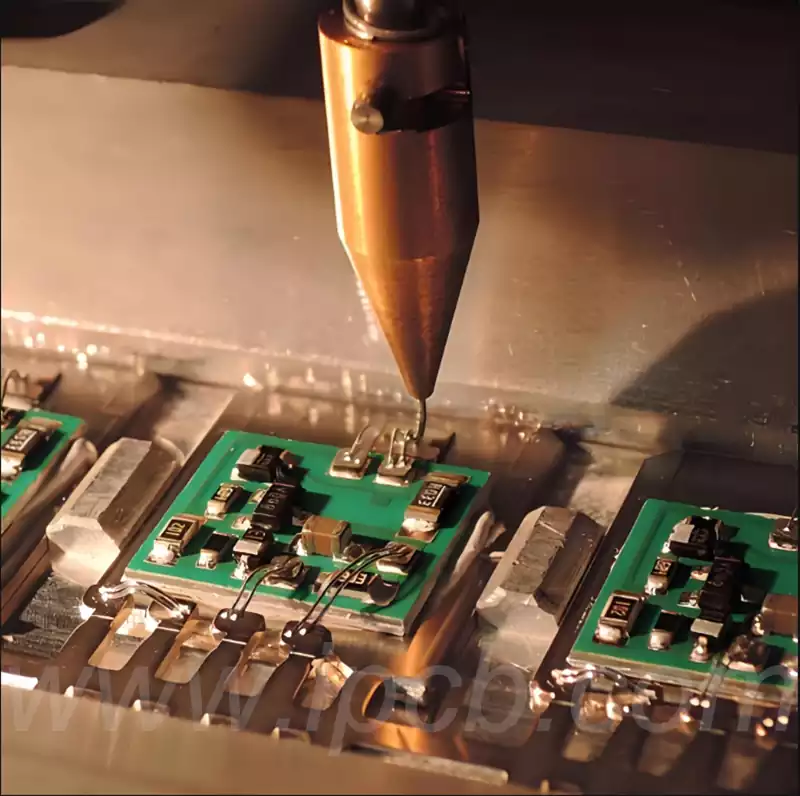

High production efficiency: the design and manufacture can realize automatic production, which improves production efficiency and reduces the error and loss of manual operation.

Easy to repair and upgrade: The circuit structure is clear and the connection between components is clear, which makes repair and upgrade easier. When an electronic product fails, the problem can be solved by replacing or repairing specific components on the PCB board.

Easy to automate production: Using computers to control the production of the PCB board allows for high-speed, high-precision mass production.

Cost-effective: relatively low production costs, high performance, and high reliability at the same time, making the whole electronic equipment more cost-effective.

The main PCB board has a wide range of applications in many fields:

Medical equipment: Many precision instruments and devices in medical equipment require main PCB board to realize their functions. For example, pH meters, heartbeat sensors, temperature measurements, electrocardiographs, electroencephalographs, MRI machines, X-ray machines, CT scanners, blood pressure machines, and blood glucose level measurement devices are all designed and manufactured based on main PCB.

Industrial equipment: The main PCB is mainly used to control and drive various mechanical devices. For example, large servo motor drivers, lead-acid battery chargers, garment cotton machines, etc. all require main PCBs to realize their functions.

Lighting: LED lights and high-intensity LEDs are important products in the field of modern lighting, and the design and manufacture of their circuit systems cannot be separated from the main PCB board. Aluminum substrate PCB has good heat dissipation and is suitable for high-power LED circuits.

Automotive and aerospace industry: In the automotive and aerospace industry, the main PCB is mainly used to control and monitor various systems. For example, sensors, control systems, and instrument panels in aircraft and automobiles require main PCBs to realize their functions.

As the core component of electronic equipment, the main PCB board has irreplaceable importance. Its high efficiency, stability, reliability, and other characteristics for the normal operation of various electronic equipment provide a solid foundation.