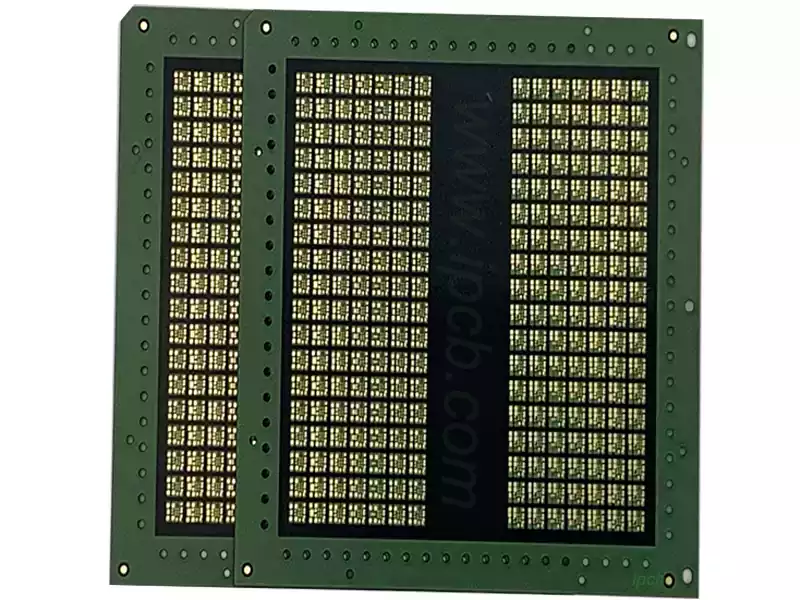

Metal pcb board is the basic material for manufacturing electronic and opto-electronic devices, and it is an indispensable and important part of circuit boards and chip packages and other fields.

Metal substrates are mainly used to solve the problems of thermal conductivity and load-bearing, and are often used in the manufacture of fused capacitors, power modules, LEDs, etc. in electronic devices. This substrate has good thermal conductivity, high stability and reliability, and can meet the requirements of high-performance electronic devices. By the metal substrate (such as aluminum, copper, iron, silicon steel plate), high thermal conductivity insulating medium layer and copper foil composition. Insulating medium layer is generally used in high thermal conductivity epoxy glass fiber cloth bonding sheet or high thermal conductivity epoxy resin, the thickness of the insulating medium layer is 80 μm-100 μm, the thickness of the metal plate specifications for 0.5 mm, 1.0 mm, 1.5 mm, 2.0 ma, 3.0 mm.

According to the structure of the metal pcb, there are three common types: metal substrate, coated substrate and metal core substrate. Metal substrate made of metal plate (aluminum, copper, iron, molybdenum, etc.), the surface is covered with an insulating dielectric layer and a conductive layer (copper foil); coated metal substrate is covered with a layer of glaze on six surfaces of the metal plate and sintered into a whole substrate, on the substrate through the leakage, sintering, silk screen, etc. to make the conductor circuit diagram; metal core substrate is generally copper, aluminum as the core material, the surface plated with organic polymer insulating dielectric layer, or Composite in the semi-cured sheet or PET film, and plated with a conductive foil (some direct addition to form a conductive pattern). Among them, the metal substrate is the most common and most used one.

Metal clad pcb can be divided into:

Aluminum-based copper-clad laminates;

Copper-based copper-clad laminates;

Iron-based copper-clad laminates;

Molybdenum-based copper-clad laminates.

Characteristics and applications of various metal substrates:

Iron-based copper-clad laminates and silicon steel copper-clad laminates have excellent electrical properties, magnetic conductivity, voltage resistance, and high substrate strength. Mainly used for brushless DC motors, tape recorders, recording machines with spindle motors and intelligent drives. However, the magnetic properties of silicon steel copper-clad plate are better than those of iron-based copper-clad plate; copper-based copper-clad plate has the basic properties of aluminum-based copper-clad plate, and its heat dissipation is better than that of aluminum-based copper-clad plate; this kind of substrate can carry high current, and is used for manufacturing power electronics and automotive electronics and other high-power circuits with PCB, but the copper substrate has high density, high value, and is easy to be oxidized, which makes its application limited, and its dosage is far lower than that of aluminum-based copper-clad plate.

Aluminum-based copper-clad laminates have excellent electrical properties, heat dissipation, electromagnetic shielding, high voltage and bending plus q-, ah energy, mainly used in automobiles, motorcycles, computers, home appliances, communications electronics, power electronics. Metal PCB substrate to aluminum-based copper-clad laminate market with the largest amount.

Copper substrate is the most expensive type of metal substrate, its thermal conductivity is many times better than the aluminum substrate and iron substrate. Copper substrate is divided into gold-immersed copper substrate, silver-plated copper substrate, tin-sprayed copper substrate, oxidation-resistant copper substrate and so on.

Advantages:

Thermal expansion

The metal substrate can effectively solve the heat dissipation problem, so that the thermal expansion and contraction of different substances of the components on the circuit board can be alleviated, and the durability and reliability of the electronic equipment can be improved.

Heat Dissipation

At present, many double-sided boards and multilayer boards have high density and high power, and it is difficult to emit heat; and metal-based printed circuit boards can solve this heat dissipation problem.

Dimensional stability

Metal substrate size is much more stable than the insulating material of the board.

Metal pcb board with its excellent thermal conductivity, carrying capacity and stability, in the electronics industry occupies a pivotal position. Whether it is power electronics, automotive electronics or communication electronics, it plays an indispensable role.