What are microchips?Microchips are small, highly integrated electronic components, usually incorporating a processor, memory, input/output interfaces, and other functions. These chips are widely used in various fields, such as computers, cell phones, and home appliances, because of their small form factor and powerful functions. The design and manufacture of microchips relies on advanced semiconductor technology that allows them to contain a large number of electronic components in a very small space.

Microchips have penetrated into many fields and become one of the basic components in the development of modern science and technology, and are widely used in consumer electronics, communications, computers, medical and other industries.

- Consumer electronics

In the field of consumer electronics, microchips are widely used in products such as smartphones, tablets and home appliances. These chips provide computing power, storage function and data transmission capability for the devices, which enhance user experience and device performance. - Communication technology

The application of microchips in the field of communication is particularly important, especially in mobile communication, wireless communication and satellite communication. Cell phone chips and baseband chips are indispensable parts of modern communication devices, which promote the development of global communication technologies. - Medical devices

Microchips are increasingly used in medical devices, especially in portable and smart medical devices. They are able to monitor health data in real time and improve the accuracy and efficiency of medical services. - Industrial Automation

In the industrial field, microchips are commonly used in automation equipment and robots. They enable efficient control and processing functions to improve productivity and automation. - Internet of Things (IoT)

Microchips are at the heart of IoT devices, facilitating the development of smart homes, smart transportation and smart cities. These chips provide the technical foundation for interconnectivity between devices. - New energy

In the field of new energy, microchips are used for energy management and monitoring, facilitating the implementation of sustainable energy solutions. This includes the application of solar and wind power to improve energy efficiency and reduce energy costs.

Steps in the microchip process

The working process of microchips can be understood in the following steps:

Power access: When the chip is powered up, it first generates a startup instruction to initialize its internal operations.

Information Processing: The chip is able to receive and process input commands and data from external sources. These input data are converted into binary signals that are processed through the switching states of the transistors.

Logic operations: The microchip performs specific operations and data processing according to set programs and logic rules. These operations can be arithmetic operations, data storage or logic judgment.

Output signals: After processing, the chip outputs the results in the form of electrical signals for use by other devices or systems.

Microchip storage

Inside a microchip, information is stored in binary form, and all data is converted into 0s and 1s. Transistors program the combination of these binary data to memorize and process complex information. For example, the microchip inside a bank card contains important information about the cardholder, all in binary form.

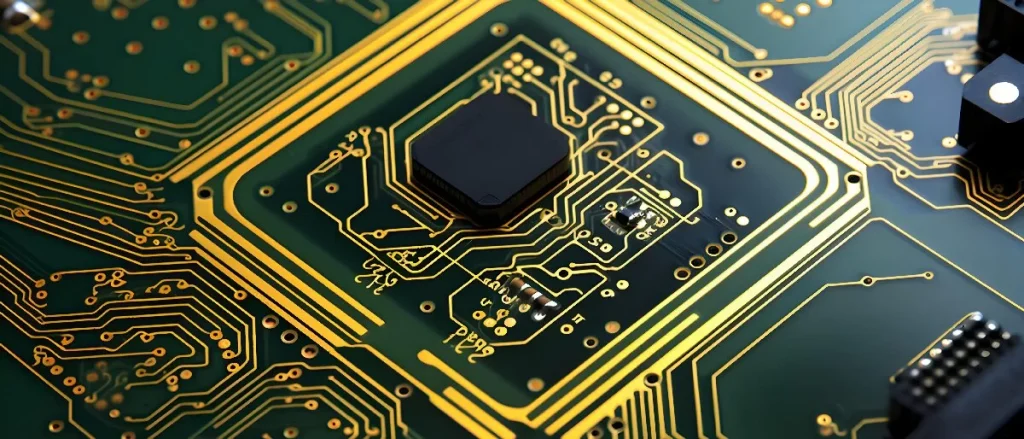

Microchip manufacturing process

- Design stage

The microchip manufacturing process begins with the design phase, which involves defining the purpose, specifications and performance of the chip. The design is divided into several parts, including specification definition, system-level design, front-end design and back-end design. These design steps help to ensure that the chip will meet the performance and functionality requirements during the subsequent manufacturing process. - Material Preparation

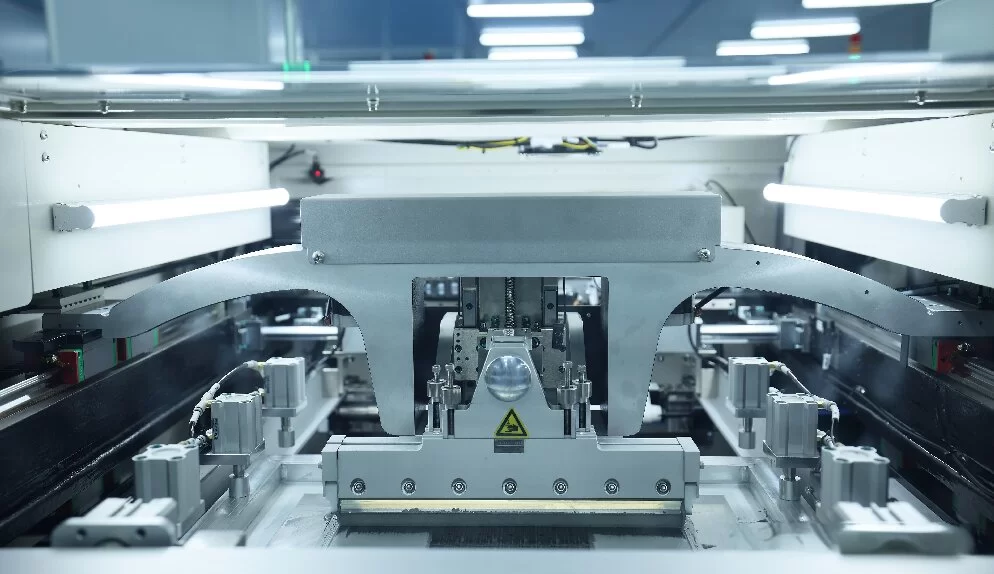

In the material preparation stage, silicon wafers are mainly used as the substrate of the chip, while various chemicals are required for processes such as deposition, etching and doping. The preparation of wafers is an important part of this stage, by processing high-purity silicon materials into thin sheets suitable for manufacturing. This step ensures the quality and purity of the materials required in the chip manufacturing process. - Photolithography

The photolithography process is an important step in the chip manufacturing process, including wafer cleaning, photoresist coating, soft drying, exposure and development. The photoresist will form patterns on the wafer, which will be used as masks for subsequent etching processes. Through these steps, the designed circuit pattern can be transferred to the wafer surface. - Etching Process

The etching process is used to remove the chip material to form the desired microstructure. Dry etching and wet etching are the main methods used in chip manufacturing. Dry etching typically uses an ion beam for material removal, which is highly accurate and capable of forming complex structures. The etching step allows the interconnection of circuit layers within the chip and also provides the necessary channels and contact holes for subsequent processes. - Ion Implantation

Ion implantation is the process of injecting dopants into the semiconductor material by means of an accelerated ion beam, which is a key step in modulating the electrical properties. After ion implantation, the wafer is typically subjected to a high temperature annealing process to repair lattice damage caused by the implantation and to activate the dopants. This step is critical to ensure the electrical properties of the chip. - Metallization Process

In the metallization process, contact holes are created in the surface layer of the chip and metals are deposited by vacuum evaporation or sputtering. These metals are typically used for electrical connections, forming interconnections between components within the chip. The metallization process emphasizes the selection of appropriate metal materials to ensure good electrical conductivity and reliability. - Packaging and Testing

Packaging is the final step in chip manufacturing and involves protecting, encapsulating and connecting the manufactured chip to external circuitry. This stage also includes performance testing of the chip to ensure its reliability and stability in practical applications. The choice of packaging depends on the specific application and requirements of the chip.

Microchips play an irreplaceable role in modern science and technology, and their applications will become more and more widespread in the future with the development of artificial intelligence, the Internet of Things and new energy technologies.