Military circuit board, is specially designed circuit boards that are widely used in military applications. These circuit boards undergo rigorous testing and certification programs to ensure that they can continue to operate under extreme conditions. They have higher resistance to corrosion and protection and meet higher reliability and durability requirements.

Key features of military circuit board:

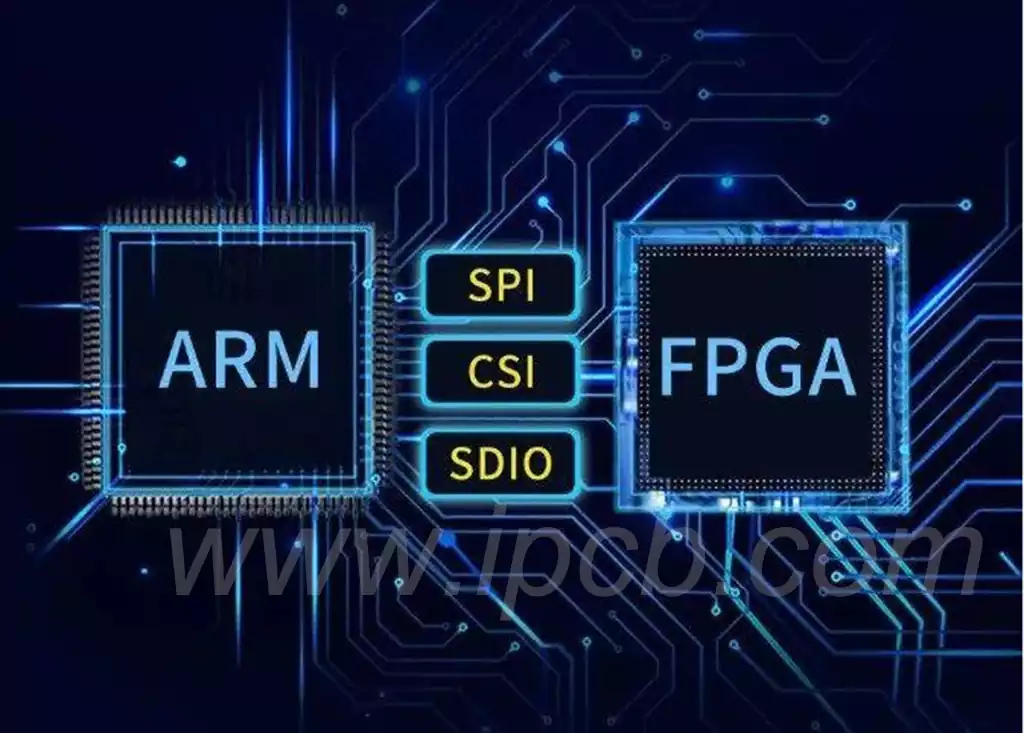

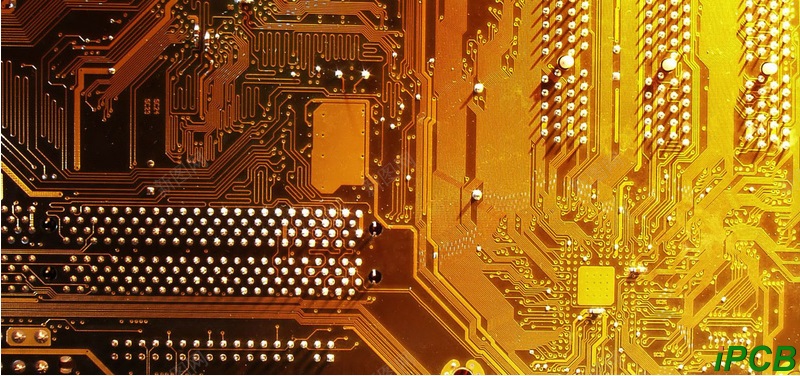

High Density: a multi-layer design is usually used, allowing more circuit components and signal transmission lines to be realized in a limited area. This high-density design improves the integration and performance of the circuit, thus meeting the needs of military systems for high-speed data transmission and complex signal processing.

High Reliability: They undergo rigorous testing and quality control during production to ensure stable operation for long periods of time in harsh environments (e.g., high temperature, low temperature, high humidity, strong vibration, etc.). In addition, they use high-quality materials and advanced production processes to improve product reliability and stability.

High-speed transmission: In order to meet the high-speed requirements of military communications and data processing, high-speed signal transmission technology and high-frequency circuit design are used. This enables the military circuit boards to realize high-speed data transmission and signal processing, adapting to the needs of modern military communication and data processing fields.

Excellent electrical performance: Compared with commercial PCBs, they have lower resistance and higher capacitance, which improves the speed and stability of signal transmission. They also have lower signal loss and electromagnetic interference, ensuring stable operation of electronic equipment in complex environments.

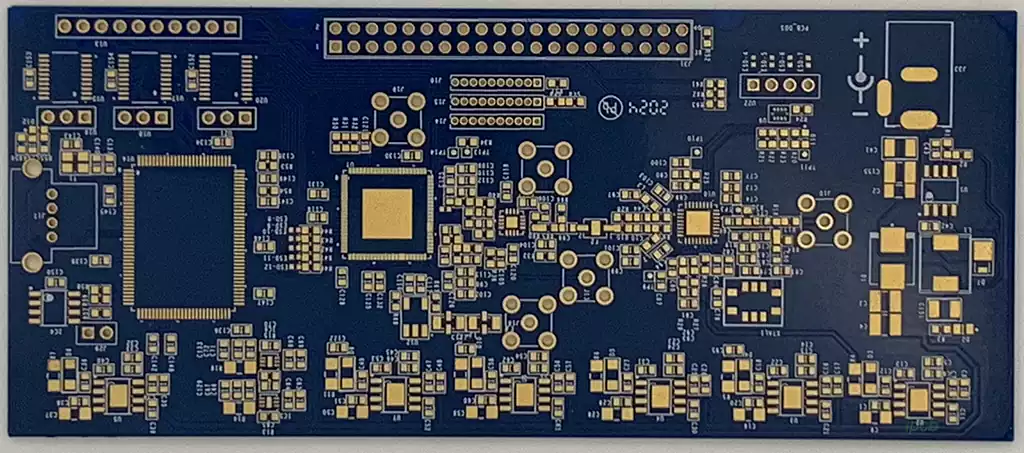

Customized design: Due to the special nature of military applications, customized designs are often required to meet specific needs. This includes special dimensions, shapes, connections, etc. to meet the specific requirements of military equipment for electronic systems.

Long service life: It is usually necessary to have a long service life in order to adapt to the long service life of military equipment. Therefore, the durability and long-term stability of the product are taken into account in the design and manufacturing process.

In the field of military industry, PCB circuit boards, as the core component of electronic equipment, have a significant impact on the reliability and stability of the entire system in terms of quality and performance. However, with the intensification of market competition, cost control and price competitiveness have become challenges for military circuit board manufacturers.

First of all, material cost is one of the important factors affecting the total cost.

Due to the high demand for product quality in the military field, manufacturers must select high-quality materials and ensure that they meet military standards. However, these high-quality materials are usually expensive, so manufacturers need to control material costs by optimizing procurement channels and reducing procurement costs.

Secondly, the production process is also one of the key factors affecting costs.

In the manufacturing process, the use of advanced production equipment and technology can improve production efficiency, reduce scrap rate, and reduce production costs. In addition, fine management of the production process, improve the stability and flexibility of the production line, can also effectively reduce costs.

In addition, the design of military circuit board also has an impact on cost control and price competitiveness.

Reasonable design can reduce material waste and cost, and improve product integration and performance. By optimizing the design and reducing the number of layers, area and weight of the circuit board, the manufacturing cost can be reduced and the competitiveness of the product can be improved.

In the face of fierce market competition, military circuit board manufacturers also need to enhance price competitiveness by improving production efficiency and reducing operating costs. By introducing automated equipment, optimizing processes, and improving employee skills, production efficiency can be improved, labor costs can be reduced, and production lead times can be reduced.

The cost and expense structure of military PCB is complex and diverse, and these costs not only affect production efficiency and product quality, but also directly relate to the performance and stability of military equipment. Therefore, the balance and optimization of costs and expenses need to be fully considered in the production and use process to ensure the efficient operation of military equipment and the security and stability of the country.