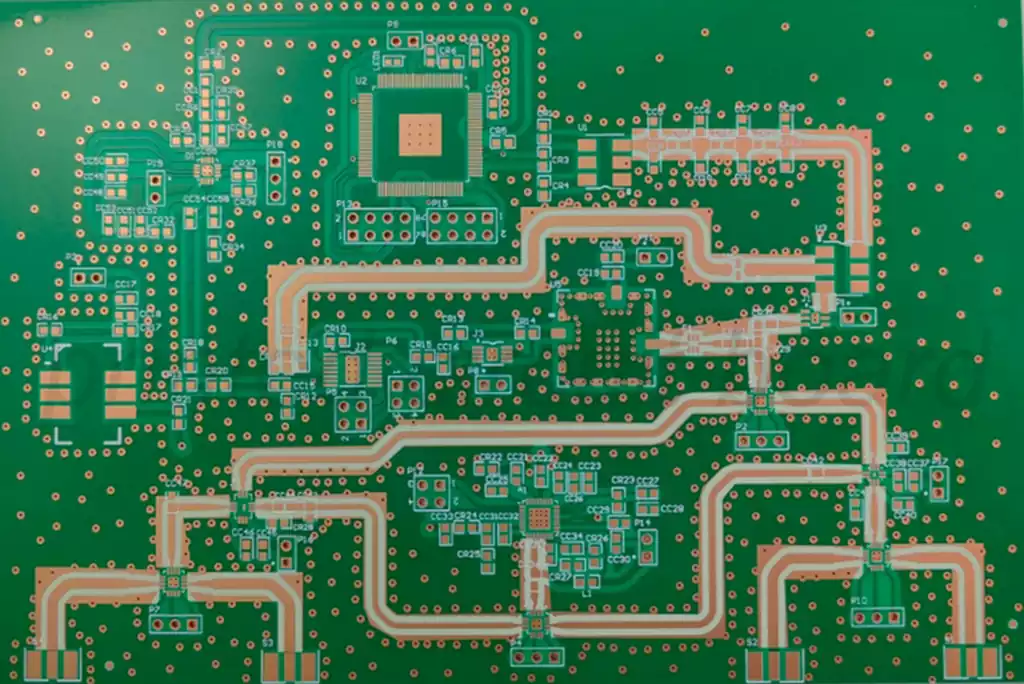

Turnkey PCB assembly is a service approach in which the supplier takes full responsibility for all processes of the PCB project, including the procurement of electronic components, the manufacture of printed circuit boards, PCBA assembly services, PCBA testing, final assembly and testing, and shipping. This service model aims to provide customers with a “plug and play” product, ensuring that the product is complete and ready to use at the time of delivery. In the PCB assembly industry, Jingbang is one of the well-known companies providing such services. By utilizing this type of service, customers can shorten the product development cycle, reduce production costs, and ensure the high quality and reliability of their products.

PCB assembly Advantages

Save Time: By having a turnkey manufacturer handle the entire PCB assembly, customers can save valuable time and focus on other aspects of their business.

Reduced Costs: Turnkey services are priced far more efficiently than bundled services, thus helping customers reduce costs.

Proof of Concept: Turnkey PCB assembly providers ensure that customers get high-quality boards without having to assemble them themselves, saving them valuable time.

Early detection of problems: The main advantage that arises when using turnkey PCB assembly at the prototype stage is also the early detection of any problems, reducing the cost and hassle of making design changes later in production.

Better management: A significant advantage of turnkey assembly is that the customer does not have to deal with multiple suppliers, making it less difficult to manage.

PCB assembly Disadvantage

Dependency: The customer may be overly dependent on the turnkey supplier, resulting in problems with the supplier that the customer may not be able to respond to quickly.

Communication problems: Inadequate communication between the customer and the supplier may lead to project schedule delays or product quality issues.

Quality control: Although turnkey PCB assembly suppliers usually provide high-quality products, if there are problems with the supplier’s quality control, the performance of the product may be affected.

Intellectual property issues: In the turnkey PCB assembly process, the customer’s intellectual property rights may be involved, requiring the customer and the supplier to agree on the ownership and protection of intellectual property rights.

Therefore, when choosing whether or not to adopt the turnkey PCB assembly model, customers need to consider these factors comprehensively and make decisions based on their own needs and goals.

Technical requirements for turnkey PCB assembly

Manufacturing processes: PCB assembly requires advanced manufacturing processes to ensure product quality and reliability. These processes include circuit board design,circuit board manufacturing, surface mounting, soldering, and so on.

Assembly technology: According to different product requirements, different assembly technologies are required. For example, SMT (Surface Mount Technology) is a technology that mounts electronic components on the surface of a PWB, while DIP (Dual In-line Package Technology) is a technology that inserts electronic components into the jacks of a PCB board.

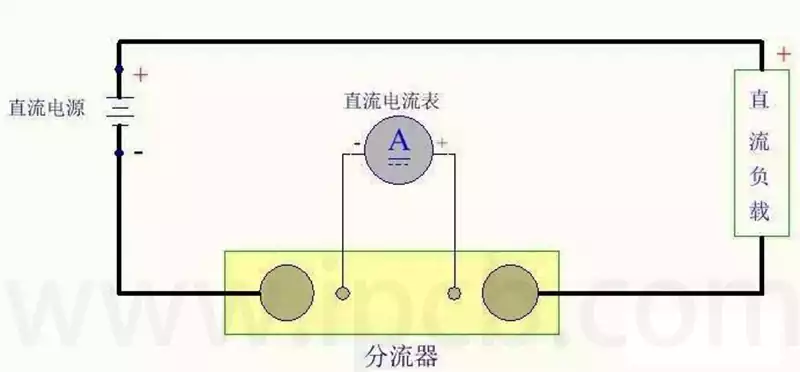

Testing and Verification: After the assembly is completed, the product needs to undergo rigorous testing and verification to ensure its performance and reliability. These tests include functional tests, performance tests, environmental adaptability tests, etc.

Quality Control: In the turnkey PCB assembly process, a strict quality control system needs to be adopted to ensure that the quality of each link meets the requirements. This includes the inspection of raw materials, quality checks during production, finished product inspection, etc.

Document management: it involves several links and processes, so you need to establish a comprehensive document management system to ensure that each link has the corresponding document records and traceability.

Supply Chain Management: it requires cooperation with multiple suppliers, so it is necessary to establish a perfect supply chain management system to ensure the supply and quality of raw materials.

Technical support and services: After the delivery of the product, the supplier needs to provide the necessary technical support and services to ensure the normal operation and use of the product.

Turnkey PCB assembly is an efficient and professional service model that provides customers with full support from PCB design to PCBA assembly.