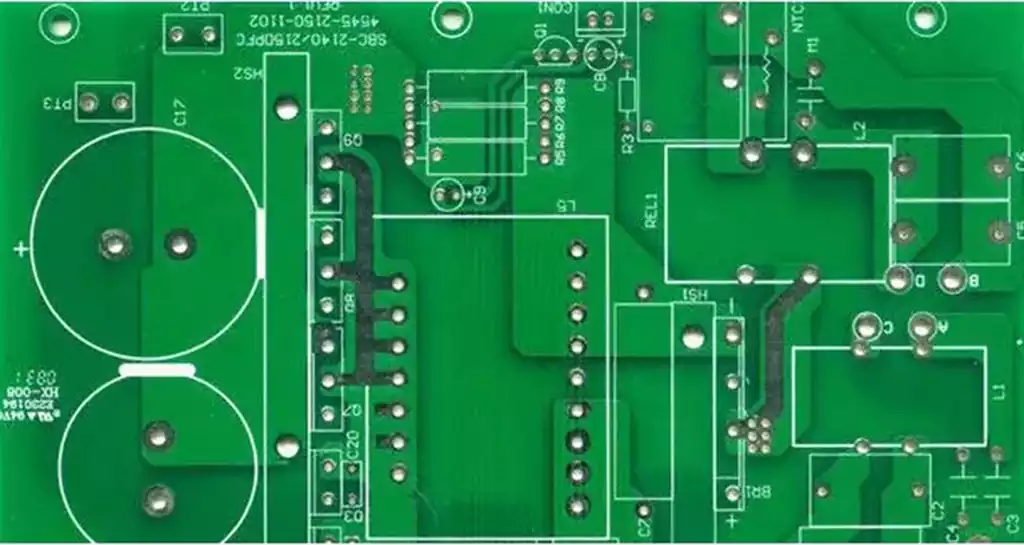

In today’s highly integrated electronic product era, circuit boards serve as core components, and pcb manufacturing costs directly impact the market competitiveness of the final product. Accurately understanding the composition of PCB expenses, mastering their calculation methods, and effectively implementing cost optimisation strategies are key to manufacturers and design engineers maintaining a competitive edge in the fiercely competitive market.

- Raw material costs:

Raw material costs constitute a significant portion of PCB manufacturing production costs. These include substrate materials, conductive copper foil, solder mask ink, drilling consumables, etc. The selection of substrate materials directly impacts PCB performance and stability, while the quality and thickness of conductive copper foil affect its price. The quality and colour of solder mask ink also influence costs. The consumption of drilling consumables is related to the number and diameter of holes in the PCB. - Equipment Depreciation and Maintenance Costs:

PCB manufacturing requires a large number of production equipment, such as photolithography machines, etching machines, and drilling machines. The purchase cost of these equipment is high, and depreciation occurs as the usage time increases. Additionally, to ensure the normal operation of the equipment, regular maintenance and servicing are required, including replacing worn parts, cleaning the equipment, and inspecting the electrical systems, which also incur certain costs. - Labour costs:

PCB manufacturing requires a large workforce, including production operators, R&D personnel, and quality control staff. Wages, benefits, and training expenses for these personnel constitute labour costs. As the labour market evolves, the proportion of labour costs in PCB manufacturing production costs is gradually increasing. - Energy and environmental protection costs:

The PCB manufacturing process consumes a large amount of energy, such as electricity and water resources. Additionally, the production process generates pollutants such as wastewater, exhaust gases, and waste residues, which require environmental protection treatment. These energy consumption and environmental protection treatment costs are also important components of PCB manufacturing production costs. - Management and R&D Costs:

To ensure the smooth operation of the PCB manufacturing process, companies must invest in management costs, including expenses related to production planning, material management, quality control, and after-sales service. Additionally, to enhance PCB performance and reduce costs, companies must engage in technological research and development and innovation, which are also important components of PCB manufacturing production costs. - Other Costs:

In addition to the above major cost components, other costs include transportation costs, warehousing costs, taxes, etc. Although these costs account for a small proportion, they should not be overlooked.

PCB expenses calculation method

- PCB expenses calculation formula and application

PCB expenses = Board cost + Process cost + Special treatment fees

Material Cost Calculation: Cost per PCB board = PCB price per square metre ÷ Number of PCBs producible per square metre

Processing Cost Factors:

Drilling Costs: Number of holes × Hole diameter coefficient (higher hole count and smaller hole diameter result in higher costs)

Line width/spacing: Precision circuits with line width/spacing less than 0.2mm/0.2mm incur a 30%-50% cost increase

Layer Cost: Each additional layer increases cost by 40%-60%

Surface Treatment: Gold plating is 20%-30% more expensive than tin plating

Special Process Surcharges:

Impedance Control: Increases cost by 10%-15%

Gold Fingers: Calculated based on gold layer area

Blind/Buried Holes: Increases cost by 25%-40%

Methods to reduce PCB expenses:

- Board material selection

The brand and performance of the PCB board material are key factors affecting cost. For example, for multilayer boards with a TG value (glass transition temperature) above 150°C, if the PP film dielectric thickness exceeds 0.2mm, using Guojì brand boards is typically more cost-effective than brands like Jiantao, Shengyi, or Nanya. However, Guojie materials are primarily suitable for single- or double-sided PCBs and are not recommended for multilayer PCBs. There are also some unknown brands of materials available on the market, which are cheaper but have relatively poorer performance and a higher likelihood of quality issues. For PCBs with eight layers or more, it is recommended to select materials with superior performance, such as Jiantao TG170, which offers a good balance between performance and cost. - Ink Characteristics

The cost of PCB ink is significantly influenced by colour and brand.

Colour: The most common solder mask ink is green, while using special colours such as blue, white, yellow, or black typically incurs additional costs.

Brand: Sun Ink is considered one of the highest-quality brands, characterised by high viscosity, stable dielectric constant, good insulation, and oxidation resistance, but it is also relatively expensive. Other brands of ink may be cheaper but may have poorer quality stability. For mass-produced products, it is recommended to use Sun Ink to ensure product stability and quality.

- Film usage

For simple batch PCBs with line widths and spacings greater than 5/5 mil, manufacturers may opt to use film to increase production capacity. The larger the PCB size, the higher the film cost, typically ranging from 100 to 200 yuan. It is worth noting that small-batch prototyping typically uses LDI exposure machines, which do not require film; however, for large-scale production aiming to maximise output, film is initially used followed by LED traditional exposure. - Line width and spacing accuracy

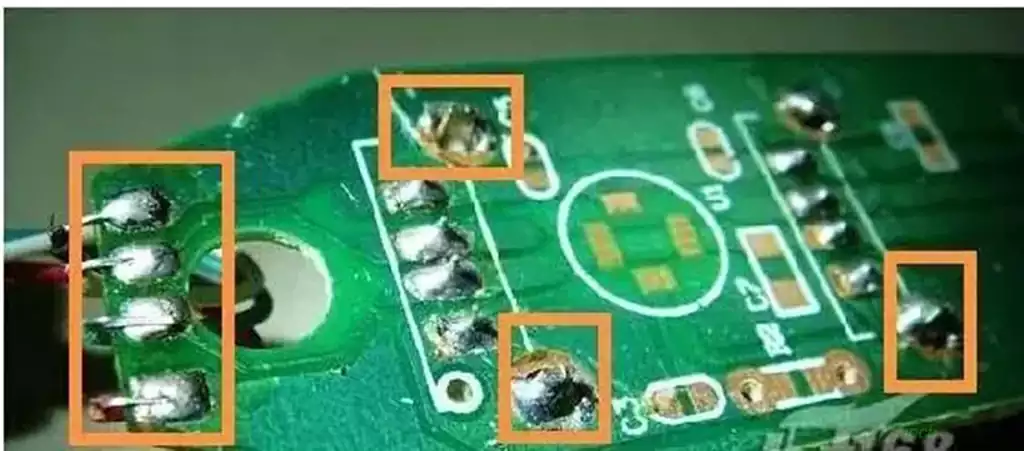

The narrower the line width, the higher the price. If the line width and spacing are below 5/5 mil, additional fees are typically incurred. This is because finer lines require higher equipment precision and chemical solution quality, and have relatively lower production yields, leading to increased costs. However, some PCB manufacturers may waive additional fees for fine lines through promotional activities. - Drilling Complexity

The size and quantity of drill holes are key factors affecting cost. Holes with diameters less than 0.3mm typically increase costs. The more holes there are, and the presence of special holes such as half-holes or PTH holes with diameters greater than 6.0mm, also increase costs. Drilling small-diameter holes in PCB materials is less efficient, as only one board can be drilled at a time, and there is a higher risk of drill bit breakage, thereby increasing production costs. - Final Copper Thickness

The final copper thickness of the PCB directly impacts cost. Boards with surface copper thickness of 2oz or higher, or hole copper thickness exceeding 25μm, will increase costs. This is because copper itself is expensive, and additional electroplating processes further increase overall costs. - Final board thickness

The final board thickness of a PCB also affects cost. For example, there is little price difference between 1.2mm and 1.6mm thick PCBs, but if the board thickness reaches 2.0mm or thicker, the cost will increase accordingly. Thicker boards require more layers of glass fibre cloth, thereby increasing costs. - Complexity of Shape

If the PCB has numerous slots (slots) with a width less than 1.0mm, this will increase costs. This is because PCBs with numerous slots are typically irregularly shaped, requiring longer processing times. Additionally, if the slot width is small, processing speeds cannot be too fast, as this may cause the milling cutter to break, reducing processing efficiency and thereby increasing production costs. - Surface Treatment Processes

Different surface treatment processes vary significantly in price. Common surface treatment processes include OSP (anti-oxidation), leaded tin plating, lead-free tin plating (environmentally friendly), gold plating, immersion gold plating, and some combination processes. The prices for these processes typically range from OSP being the lowest, followed by leaded tin plating, then lead-free tin plating, gold plating, and immersion gold plating being the most expensive. Lead-based/lead-free tin plating is widely used due to its cost-effectiveness. It is worth noting that sometimes the price of OSP may be higher than tin plating. This is because PCB manufacturers may consolidate orders from multiple customers with the same process for cost reasons, but OSP has fewer customer requests, making consolidation difficult, resulting in higher prices. - Mold fees and testing fees

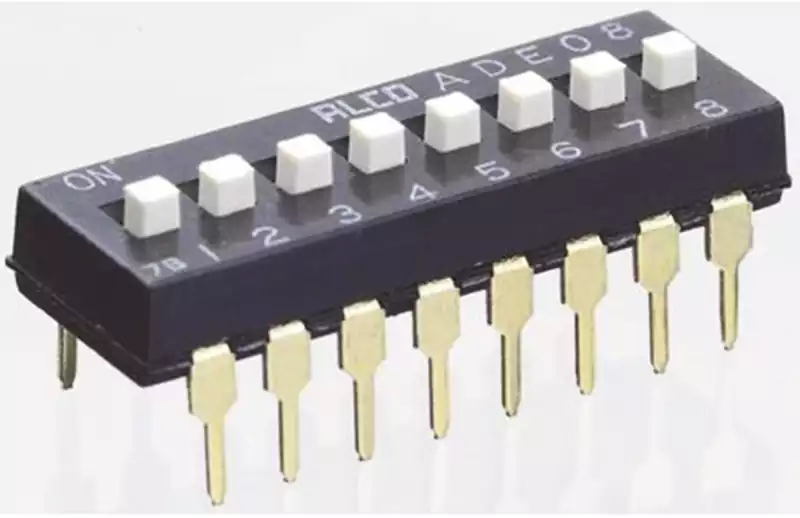

Mold fees: For prototyping or small-batch production, PCB manufacturers typically use drilling and milling for the board outline, without additional milling fees. However, for large-scale production, a mold must be created for stamping the boards, which incurs a mold fee, typically quoted at over 1,000 RMB by PCB manufacturers.

Testing Fees: For prototyping or small-batch production, flying probe testing is typically used, with costs ranging from 100 to 400 RMB, depending on the number of test points in the file. For large-scale production, test fixtures are required for testing. While the cost of the test fixture itself ranges from 1,000 to 1,500 RMB, it offers higher efficiency and lower overall costs.

PCB manufacturingcosts constitute a complex and dynamic system, encompassing every stage from raw materials to final testing. By thoroughly understanding these cost components and implementing refined strategies in design, material selection, process flows, and order management, companies can more effectively control PCB expenses, thereby enhancing overall competitiveness and profitability while ensuring product performance and quality.