A stencil printing is an important tool used in the PCB manufacturing process. stencils used in electronics factories are mainly used in the manufacture of parts of printed circuit boards. They are an integral part of modern electronics, and it can not be made without the use of stencils in electronics factories. A stencil is a customized grid structure tool, usually made up of metal wires, that is mounted on a printing press for printing and curing the boards.

The main function of an electronics factory stencil is to print and cure circuits while formulating circuit boards for the electronic manufacturing process. Specifically, electronic factory stencils can fulfill the following roles:

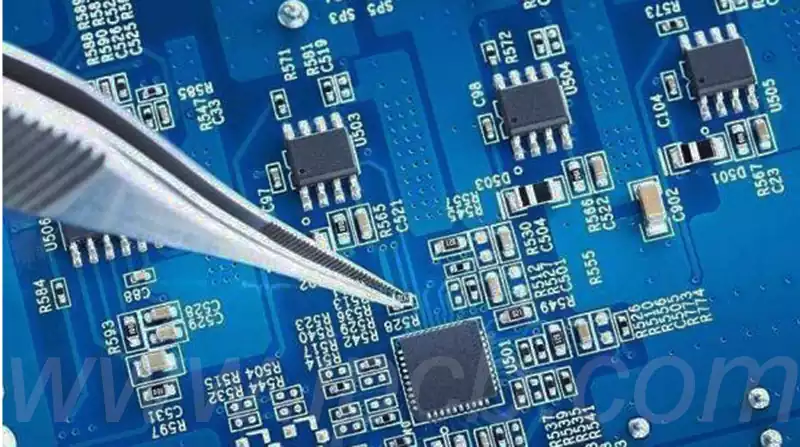

- Printing of circuit patterns: The necessary patterns are made on the stencil according to the design and printed on the pcb substrate by means of a printing machine.

- On-demand selection: The electronic factory stencil can be used to develop circuit patterns and structures according to specific needs, which ensures that the produced pcb boards meet the standards and quality requirements.

- Ensure circuit connectivity: Stencils ensure proper connectivity between each component on the board and create stable circuit connections throughout the board.

Types of Electronic Factory Stencils printing

According to different functions and printing requirements, electronic factory stencils are usually categorized into several types, including:

- diameter stencils: also known as single-layer stencils, they are usually used for printing single-sided pcb or double-sided pcb substrate that require only single-sided patching.

- double layer stencils: used for making double-sided pcb boards, two layers of stencils are printed on each side.

- Multi-layer stencils: can print multiple layers of pcb substrate, often used for complex multi-layer pcb.

SMT stencil production materials

- Mesh frame

Mesh frame is divided into movable and fixed mesh frame, movable mesh frame directly mounted on the frame, a mesh frame can be used repeatedly; fixed mesh frame is glued to the screen yarn overlaying the mesh frame, the latter is fixed by glue. Fixed mesh frame is easier to obtain uniform tension of the steel sheet, the tension size is generally 35 ~ 48N/cm2. (Normal fixed mesh frame of the allowable tension of 35 Newton-42 Newton)

2.Mesh yarn

Mesh yarn is used to fix the steel sheet and frame, which can be divided into stainless steel wire mesh and polymer polyester mesh. Stainless steel wire mesh commonly used 100 mesh or so,can provide more stable enough tension, only after a long time, stainless steel wire mesh is easy to deform the loss of tension; polyester mesh mesh fly organics is often used 100 mesh, it is not easy to deform, long service life.

- Sheet

That is, used to open the hole of copper, stainless steel, nickel alloy, polyester, etc..Templates generally use foreign high-quality 301/304 stainless steel sheet, foreign steel sheet with its excellent mechanical properties greatly improve the service life of the template.

4.Glue

Used to paste the mesh frame and steel glue in the template in the role of the larger, can be used for the use of different customers, specialized glue, this glue can maintain a strong adhesion, and can resist a variety of template cleaning agent complex cleaning.

Manufacturing method of smt stencil

Chemical Etching Stencil

The use of corrosive chemical solution corrosion elimination of stainless steel sheet needs to open the location of the metal, and PCB pads corresponding to the openings, chemical etching stencil manufacturing process: cutting the appropriate size of the steel sheet → cleaning → coating photoresist material → UV exposure → developing, drying → chemical etching → stripping photoresist material → cleaning, drying → inspection → taut mesh → packaging.

Laser cutting stencil

Cutting and punching holes in stainless steel sheets with a high-energy laser beam to obtain the desired stencil technology. Laser cutting stencil manufacturing process: data processing → laser perforation → grinding, electropolishing → inspection → taut mesh → packaging.

Electroforming Stencil

Inside the stencil manufacturing belongs to one of the most complex technology, using electroplating into the process, electroforming stencil manufacturing process: coated photographic film on the substrate → production of the mandrel → electroplating nickel in the mandrel around the generation of steel → stripping cleaning → inspection → tensile mesh → packaging.

Mixed process stencil

Step stencil production process technology, that is, in a stencil to retain more than two kinds of thickness, to meet the different components on the board of different requirements for the amount of tin. Ladder stencil manufacturing process: the combination of the previous three stencil processing technology in one or two to jointly produce a completed stencil.

PCB stencil printing, as a key part of PCB manufacturing, its design and production technology continues to improve, not only to enhance the circuit board manufacturing accuracy and quality, but also to promote the rapid development of the entire electronics industry. Looking ahead, it will continue to play a central role in the electronics manufacturing industry, leading a new chapter of technological innovation.