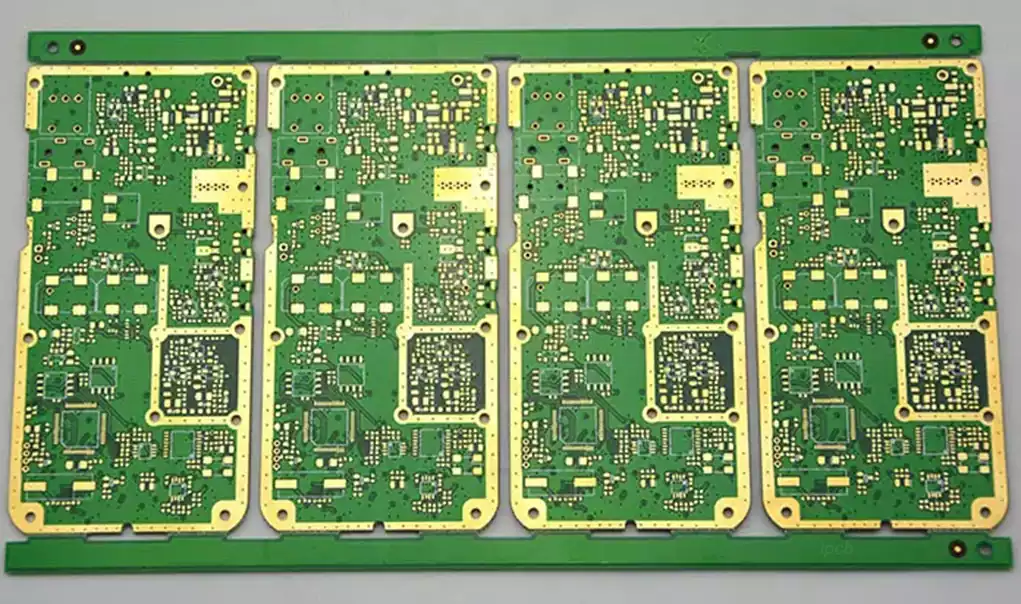

In the electronics industry, the surface treatment of printed circuit boards (PCBs) is a critical step in ensuring stable connections between components, improving corrosion resistance, and enhancing electrical conductivity. Immersion gold and gold plating are two commonly used surface treatment methods, each of which has its own advantages and is suitable for different application scenarios.

Process Overview

Immersion gold, also known as chemically nickeled gold or autocatalyzed gold, is a process that deposits a thin film of metal on the surface of a PCB through a chemical reduction reaction. In this process, the PCB is immersed in a solution containing metal ions, which are reduced and deposited on the board under the action of a catalyst.

Gold plating, on the other hand, is an electrochemical deposition process in which metal ions are deposited onto the surface of the PCB by applying a voltage to an electrolyte in the presence of an electric field. In the gold plating process, the thickness and nature of the metal layer can be precisely controlled by adjusting the plating parameters.

Performance Comparison

Corrosion resistance: The metal layer formed by the gold deposition process has excellent corrosion resistance and can protect the PCB from oxidation and corrosion for a long time. The corrosion resistance of gold-plated layers depends on their thickness and the type of metal, and thicker gold-plated layers usually have better corrosion resistance.

Conductivity: immersion gold and gold-plated have good conductivity, but the immersion gold layer is usually thinner than the gold-plated layer, so in some of the very high conductivity requirements of the application, you may need to choose the gold-plated process in order to obtain lower resistance.

Solderability: Immersion gold layers have a flat surface and good wettability, making the soldering process more reliable. Gold-plated layers may require additional treatment before soldering, such as the removal of oxidized layers or the addition of wetting agents, to ensure good soldering results.

Application Scenarios

Due to its excellent corrosion resistance and solderability, the immersion gold process is often used in areas with high-reliability requirements, such as aerospace, military, and medical equipment. These applications require a high level of performance and stability of the PCBs, which the immersion gold process is able to meet.

Gold plating is more suitable for general electronics and consumer electronics. In these applications, the balance between cost and performance is more critical, gold plating process by adjusting the thickness and nature of the metal layer, can meet the performance requirements while reducing costs.

As two important processes for PCB surface treatment, gold immersion, and gold plating each has its own unique advantages and application scenarios. When choosing the right process, you need to consider factors such as product performance requirements, cost budget, and production environment. A deeper understanding of the characteristics and differences between these two processes can provide strong support for the design and manufacture of electronic products.