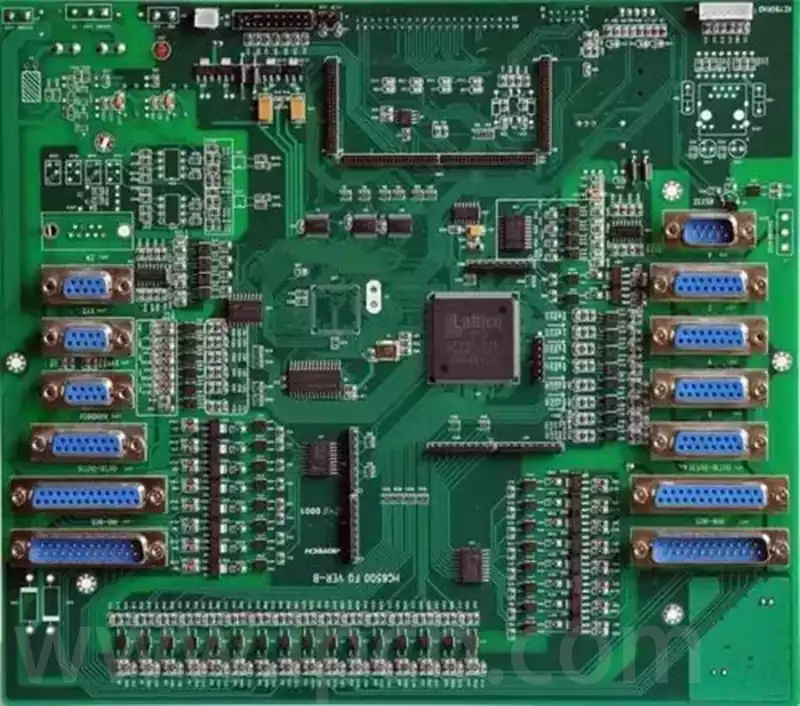

PCBA coating is the process of evenly coating the PCBA surface with a specific material,usually triple-proof paint or other protective coatings.This process is generally carried out after the PCBA has undergone placement,soldering and other processes and has completed electrical performance testing.

PCBA coating process usually includes the following core steps:

Cleaning: Remove dust,oil,flux residue and other impurities from the PCBA surface to ensure good adhesion of the coating material.Cleaning can be cleaned using a cleaning agent,and wait for the cleaning agent to evaporate completely.

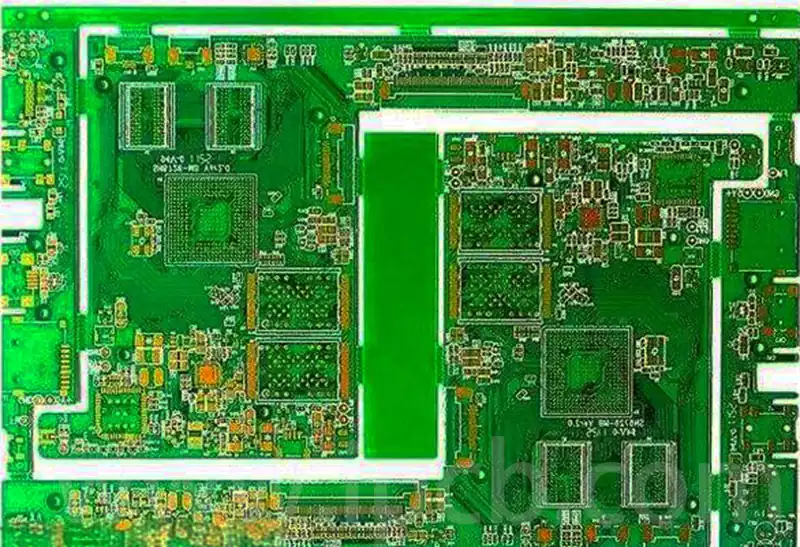

Coating: the pcba coating material (usually three-proof paint or other protective coatings) evenly applied to the PCBA surface.Coating methods include spraying, dipping, brushing,etc.The specific choice depends on the production scale,the shape of the PCBA and the coating requirements.

Curing: The coating material on the PCBA surface to form a layer of strong,stable protective film. Curing mode has room temperature curing, heating curing, UV curing, etc., heating curing can usually shorten the curing time and improve the film performance.

Inspection: check the quality of the coating to ensure that the coating is uniform, no bubbles, no leakage and other defects.

The standard thickness of the pcba coating operation is usually maintained between 0.15mm and 0.35mm, and should be carried out at a temperature of not less than 15 ℃, relative humidity of less than 70% of the environment.The application of three-proof paint is crucial for electronic products, especially in environments with large variations in temperature and humidity.It provides superior insulation protection, extends the life of circuit boards, enhances the reliability of electronic equipment, reduces maintenance costs, and effectively blocks external erosion and contamination of the product.Among them,the spraying method is a widely adopted means of coating in the industry.

Detailed steps and precautions for applying triple-proof paint:

Before painting,be sure to thoroughly remove dust,moisture and rosin and other impurities on the product surface,and keep the circuit board clean and dry to ensure that the three-proof paint can be tightly adhered to the surface of the circuit board.

When painting,the entire component and pad area should be evenly covered to avoid missing.Baking conditions are recommended to 65 ° C for 15 to 35 minutes, removed from the oven while hot paint better results.

When painting, the PCBA board should be placed smoothly on the desktop, and after painting,it should be ensured that there is no dripping phenomenon and all parts are evenly covered, and the thickness of the coating is recommended to be between 0.1mm and 0.3mm.

After painting, the PCBA board should be placed on the shelf for natural curing,or heat can be used to accelerate the curing process.

In the painting process,it should be noted that high-power components with heat-sinking surfaces or heat sinks,power resistors,power diodes,cement resistors, etc. should not be painted with triple-proof paint, and need to be covered to protect them.At the same time,the screw holes on the board should also be avoided painting.

If a thicker coating is required, two thinner coats can be applied in a stack, but the second coat should be applied after the first one is fully cured.

The operation of applying triple-proof paint should be carried out in a closed room and good ventilation should be ensured. During the operation, staff should wear protective equipment such as masks and gloves to safeguard their health.

Functions of pcba coating process

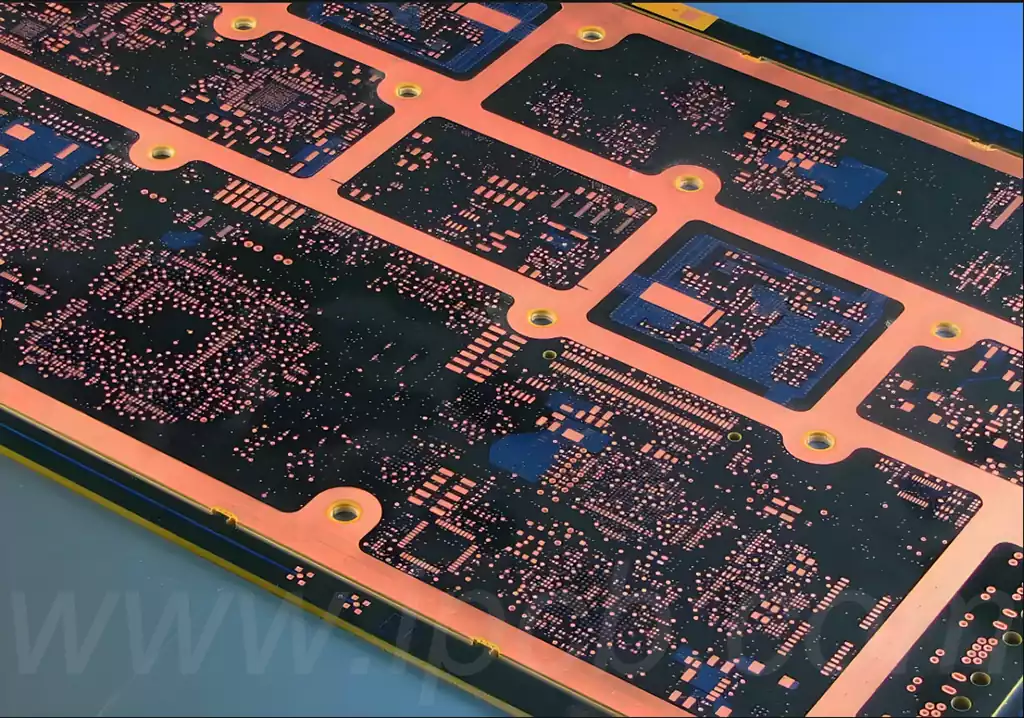

Moisture and waterproof performance enhancement:PCBAs may be challenged by humid environments during operation,and moisture infiltration may lead to short circuits or component damage.The protective layer formed by applying three-proof paint can effectively isolate moisture and ensure that PCBAs can still work stably under humid conditions.Especially in applications such as outdoor electronic equipment and bathroom appliances,the coating process can significantly enhance the moisture resistance of products.

Resistance to salt spray erosion:in the marine climate or industrial pollution is heavy in the region,the air in the salt spray component of the PCBA poses a threat, can corrode the metal components and lines,reduce electrical performance.The application of three-proof paint can block the contact between salt spray and PCBA, preventing corrosion and thus prolonging the life of the product,which is an indispensable protective measure for the coating process for marine marine electronic equipment,coastal base stations and other equipment.

Anti-dust and anti-pollution:Dust and pollutants are easy to accumulate on the surface of PCBA,which not only affects heat dissipation, but also may cause short circuit. The coating layer can effectively block dust and dirt and keep the PCBA surface clean.For electronic equipment working in harsh environments, such as industrial automation control equipment and mining electronic equipment,the coating process helps to ensure the continuous and stable operation of the equipment.

Enhance insulation safety: three-proof paint has excellent insulation properties,can prevent PCBA internal lines or components due to accidental contact and short circuit, enhance the overall safety and reliability of the circuit.In high voltage circuits,precision electronic instruments and other fields, the insulation protection function of the coating process is the key to ensure product performance.

PCBA coating process as an important link in the manufacture of electronic products,it not only significantly improves the product’s moisture-proof, waterproof, anti-salt spray erosion, dust and dirt, as well as insulation and safety performance,but also extends the service life of the circuit board,enhance the reliability of the electronic equipment, and effectively reduce the maintenance costs.With the continuous development of electronic technology,PCBA coating process will continue to optimise and innovate, to provide more efficient and environmentally friendly protection solutions for electronic products,and to promote the electronics industry to higher quality, higher reliability direction.