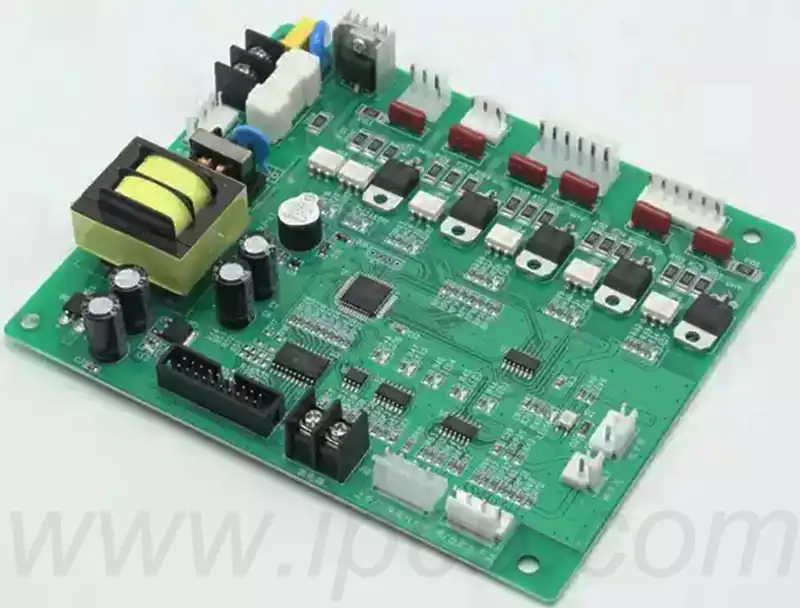

A power module PCB is a special type of circuit board whose main function is to integrate a power supply into a printed circuit board to provide a stable and reliable DC power supply for electronic devices. This kind of circuit board usually includes parts such as a power converter, control circuit, and protection circuit to realize the functions of power input, conversion, output, and protection.

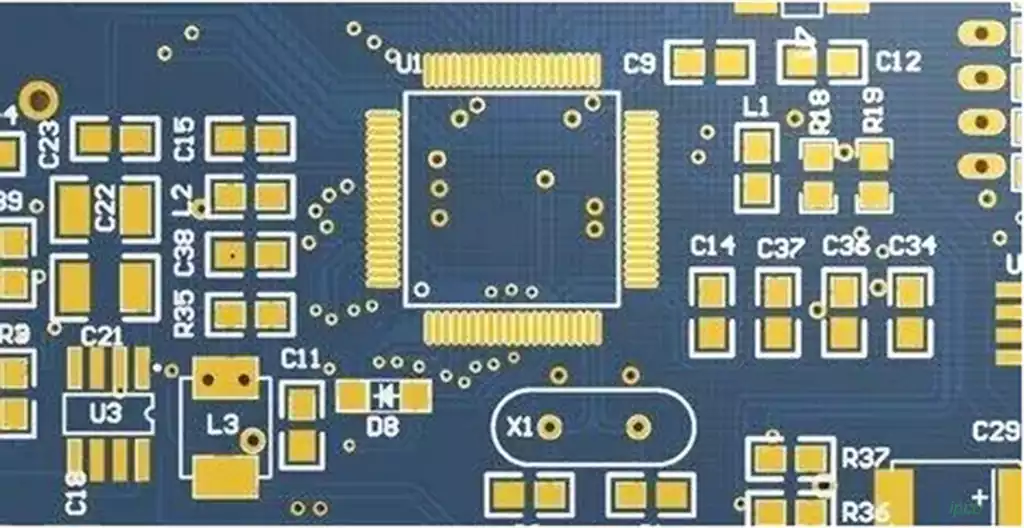

ipcb offers power module pcb process capability:

Material: High TG FR4

Layer:12Layers

Color: Green/white

Finished Thickness:1.0mm

Copper Thickness:2-3oz

Surface Treatment:immersion Gold

Min Trace : 8mil(0.2mm)

Min Space : 8mil(0.4mm)

Principle of Operation

Power module PCB is an important part of electronic equipment, and their main function is to convert the input power into a stable voltage suitable for the operation of the equipment. Power supply circuit boards are usually composed of transformers, rectifier circuits, filter circuits and voltage regulator circuits. The transformer converts the voltage of the input power supply into a voltage suitable for the equipment, the rectifier circuit converts the alternating current into direct current, the filter circuit eliminates the ripple in the power supply, and the voltage regulator circuit maintains the stability of the output voltage.

Component Structure

A power module pcb is usually composed of several electronic components, including capacitors, inductors, diodes, transistors, and so on. These components are connected together through a circuit to form a complete power supply circuit. Power supply circuit boards also include auxiliary components such as connectors, relays, fuses, etc., which are used to connect the power supply to the equipment and provide functions such as overload protection and short circuit protection.

The layout principle of the power module PCB is to comprehensively consider many aspects such as power conversion efficiency, heat dissipation performance, electromagnetic compatibility, safety and maintainability, etc., to ensure that the electronic equipment can operate stably and reliably. The main principles of power circuit board layout:

Power conversion efficiency: the first task of the layout is to ensure that the power supply can be efficiently converted from input to output to meet the needs of the device. This involves choosing the right power management chip and optimizing circuit layout and wiring to reduce energy loss and improve conversion efficiency.

Heat dissipation performance: The power supply circuit board generates heat when converting power, which, if not dissipated in a timely manner, can lead to degradation of device performance or even damage. Therefore, the layout should be considered when the heat dissipation problems, such as increasing the heat sink, optimizing air flow paths, and reasonable arrangement of components to reduce the temperature.

Electromagnetic compatibility: The power module pcb will generate electromagnetic interference during operation, which may affect the normal operation of other circuits or components. Therefore, the layout should take measures to reduce electromagnetic interference, such as reasonable wiring, and the use of filter capacitors.

Safety: The layout should ensure the safety of the power supply circuit to prevent short circuits, over-voltage, over-current, and other abnormalities. Suitable protection circuits should be set up, such as over-current protection, over-voltage protection, and so on.

Maintainability: The layout should take into account the maintainability of the equipment, such as convenient replacement of components, easy debugging and maintenance. Therefore, the layout should be clear and neat, and the identification of components should be clearly visible.

With its advantages of stability, reliability, energy saving, and compatibility, power module pcb plays a vital role in electronic equipment, providing solid support for the development of modern technology and people’s lives.