A pcb battery is a small battery on a circuit board that is used to store the board’s setup or calibration data to ensure that the board can be restored to its original operating state after a long period of inactivity. In some special cases, such as temperature sensors,the pcb battery can also provide power for the sensor.

How pcb battery works

During the discharge of a pcb battery, an electrochemical reaction takes place between the positive and negative electrodes:

Reaction at the negative electrode: During charging and discharging, the negative electrode material releases electrons to produce negative ions (usually lithium ions, depending on the type of battery). This process causes a chemical reaction between the negative electrode and the electrolyte to produce electrical energy.

Electron Flow: The released electrons flow through an external circuit to the positive electrode. At this point, the electrical energy is efficiently utilised to power external loads.

Positive Reaction: As electrons flow to the positive electrode,positive ions migrate through the electrolyte to the positive electrode,eventually combining with the electrons arriving at the positive electrode to form new compounds and complete the electrochemical reaction.

In the charging of a pcb battery, the process is the opposite of discharging:

External Power Connection: The battery is connected to an external power source and electrical energy is fed into the battery through the charging device.

Reversal of electron flow:During charging,the current from the external power source causes electrons to flow from the positive terminal to the negative terminal,during which positive ions move through the electrolyte and into the negative terminal.

Regeneration of Chemistry:As current flows,the negative electrode material re-stores electrons and the positive electrode generates the corresponding positive ions. This process allows the battery to store energy again in preparation for subsequent discharges.

Advantages of PCB Battery

Space-saving: Integrated design allows devices to provide the power they need without increasing their size. The advantages of board batteries are becoming more apparent, especially as modern electronics tend to be thinner and lighter.

Improved Performance: Board-integrated batteries can improve the overall performance and energy efficiency of a device by optimising the circuit design, reducing the number of wires and connectors, and lowering energy loss.

Flexibility: The design of pcb battery can be flexibly adapted to the needs of different applications, providing a customised power solution for a wide range of uses. Whether it’s a high power or low power application, pcb battery can be adapted to suit a wide range of needs.

Simplified Manufacturing Process: Due to the embedded circuit board design of the battery, the manufacturing process is simplified by reducing the number of additional assembly steps, which improves productivity and reduces costs.

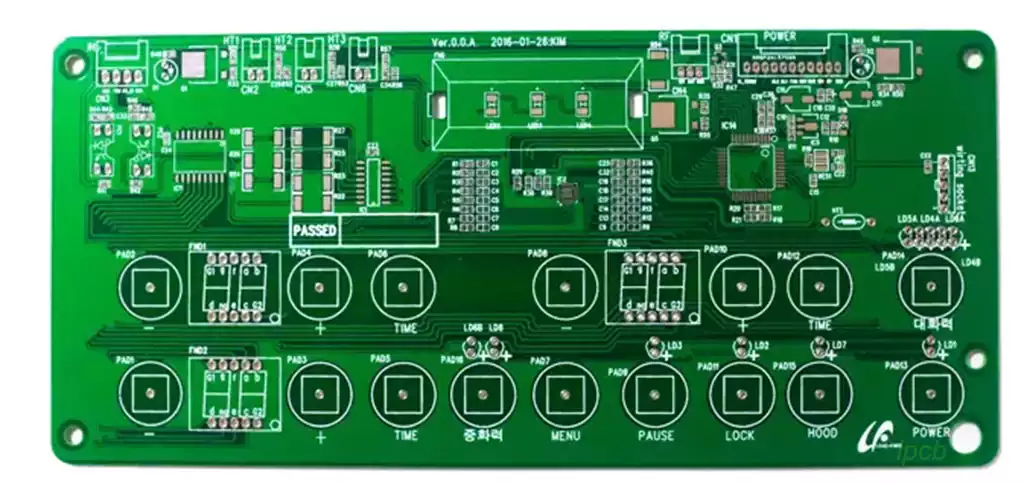

PCB battery has a wide range of applications, especially in the following areas:

Smart Wearable Devices: With the popularity of products such as smart bracelets and smartwatches, there is an increasing demand for high energy density and low volume power supplies, and circuit board batteries are able to meet the specific needs of such products.

Internet of Things (IoT) Devices: Low power consumption and long-life power supplies are important considerations in the widespread use of Internet of Things (IoT) devices.PCB battery provides long-lasting and stable power in such devices to ensure their normal operation.

Medical Devices:In medical instruments and sensors,the high integration of board batteries can effectively improve the portability and performance of the equipment,enabling patient monitoring and surgical instruments to better meet the needs of real-time data transmission and wireless operation.

Consumer electronics: Modern mobile phones, tablets and other consumer electronics require high energy density and safety performance from batteries, and board batteries are well suited as an integrated solution.

Impact of a Dead PCB Battery

When the battery on a circuit board runs out of power, the settings and calibration information stored on it are lost, causing the board to deviate. This deviation may be reflected in the accuracy of the measurement results or may cause abnormalities in the operation of the device. Failure to replace the circuit board batteries in a timely manner can cause the deviation to increase over time and,in extreme cases,can even lead to equipment damage.

When replacing pcb battery, the following key points should be noted:

It is important to ensure that the positive and negative terminals of the circuit board battery are installed correctly, otherwise the circuit board may be damaged as a result;

When carrying out pcb battery replacement, clean hands and anti-static gloves should be observed to prevent static interference or contamination;

Before replacing the pcb battery, it must be ensured that the circuit board has been disconnected from the power supply, otherwise damage may be caused to the circuit board.

PCB battery plays a pivotal role in the operation of modern electronic equipment.With the rapid development of science and technology, the performance and application areas of circuit board batteries will continue to expand. We have reason to believe that this small component will continue to bring more surprises and convenience to our life and work with its unique charm and unlimited potential.