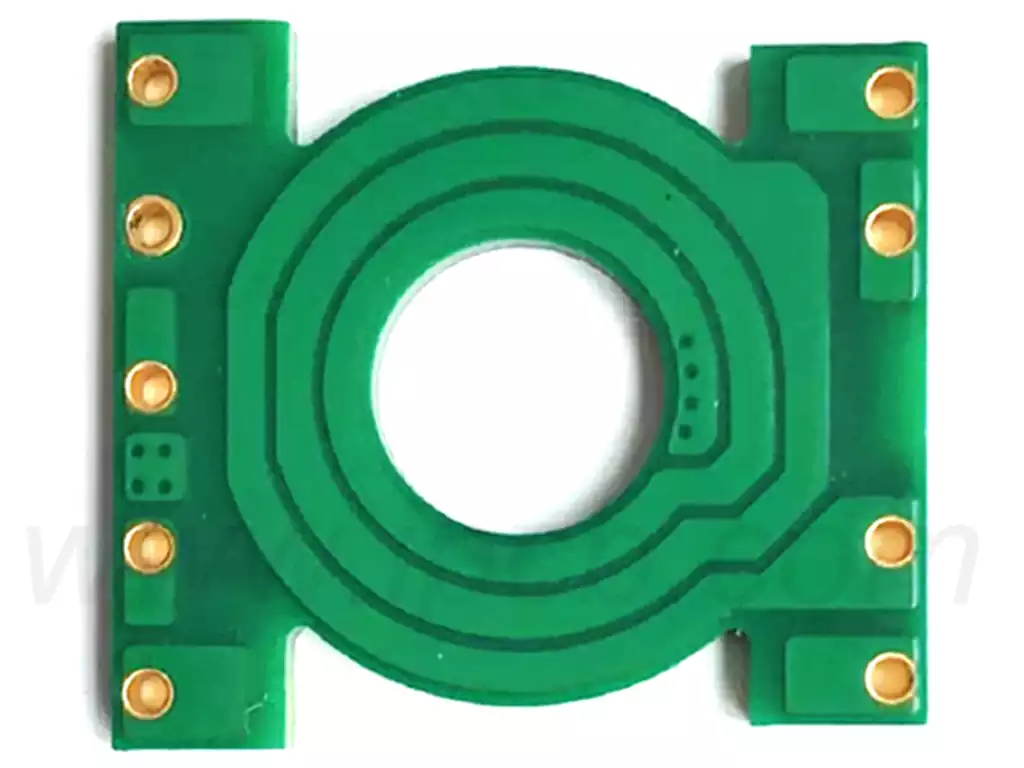

Printed circuit board router is a high-precision machine tool specialized in processing PCB.It is mainly used for milling and cutting PCBs. It uses a high-speed rotating milling cutter to accurately cut and carve PCB materials through a precise control system. This type of machining enables highly accurate dimensional control and shape processing, ensuring that the conductive paths, holes and component layouts on the PCB meet the design requirements.

The operating principle of a printed circuit board router is based on a high-speed rotating milling cutter and a precise control system. The milling cutter is usually made of carbide or ceramic material and is able to cut the PCB material while rotating at high speed. The control system is responsible for accurately controlling the position, speed and trajectory of the milling cutter to ensure machining accuracy and stability.

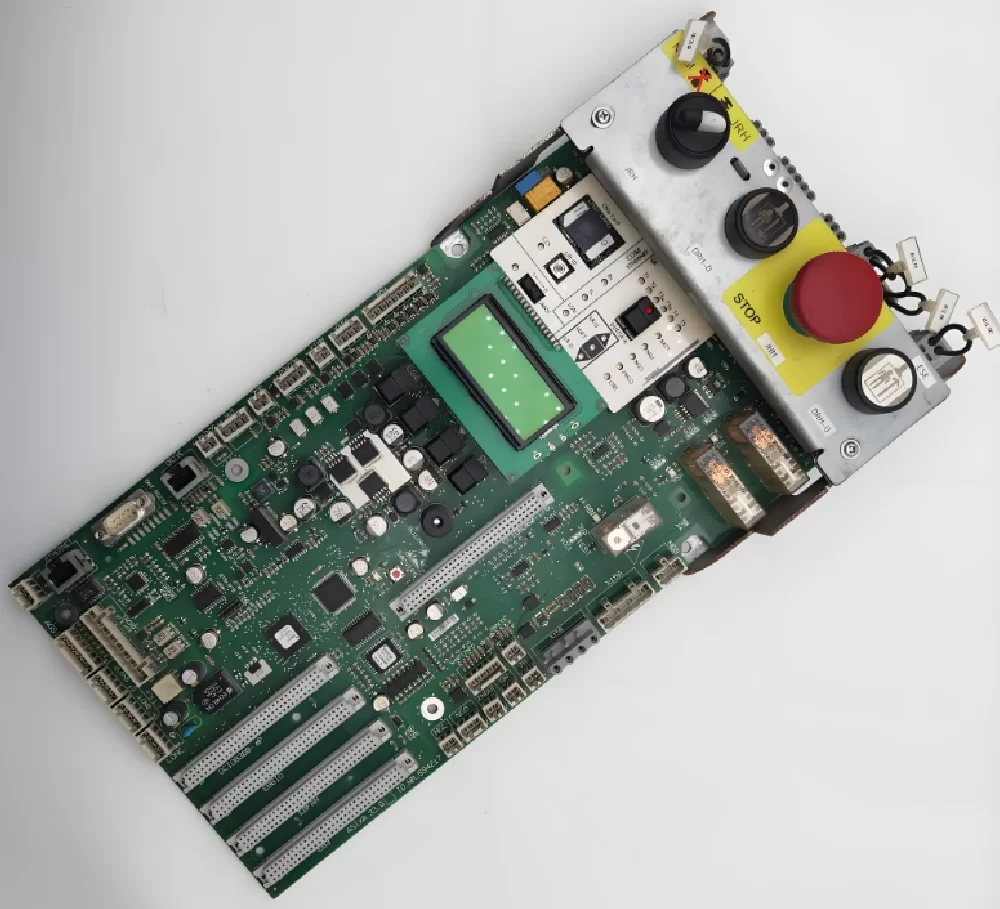

In the process of processing, printed circuit board milling machine can also be equipped with a variety of auxiliary equipment, such as coolant system, dust extraction device, etc., to ensure the smooth progress of the processing. These auxiliary equipment can not only improve the processing efficiency, but also effectively protect the machine tool and workpiece to extend the service life.

Operation process of milling machine

- Preparation: Before using the milling machine, it is necessary to carry out inspection and preparation work. Including checking whether the milling machine equipment is normal, start the milling machine tool host and hydraulic system.

- Positioning the workpiece: install the workpiece to be machined on the worktable, and make it meet the machining requirements by adjusting the table position and angle and other parameters.

- Installation of tools: according to the machining requirements to select the appropriate tool, and through the toolholder to fix the tool on the spindle.

- Adjust the tool: make it adapt to different machining requirements by adjusting the parameters such as cutting depth, feed speed and rotation speed of the tool.

- Start machining: turn on the spindle, control the tool to cut on the surface of the workpiece until it meets the machining requirements.

- Check the quality: After machining is completed, check and evaluate the machined surface to ensure that its quality meets the requirements.

- End processing: close the spindle and the hydraulic system, and the milling machine for cleaning and maintenance

The maintenance of the milling machine requires some skills, including:

(1) For the hydraulic system, change the oil and oil seals regularly to ensure the normal operation of the hydraulic system.

(2) For the spindle, clean and lubricate regularly to prevent failures caused by impurities and wear.

(3) For the cutting tool, regular inspection and grinding to ensure its cutting effect and life.

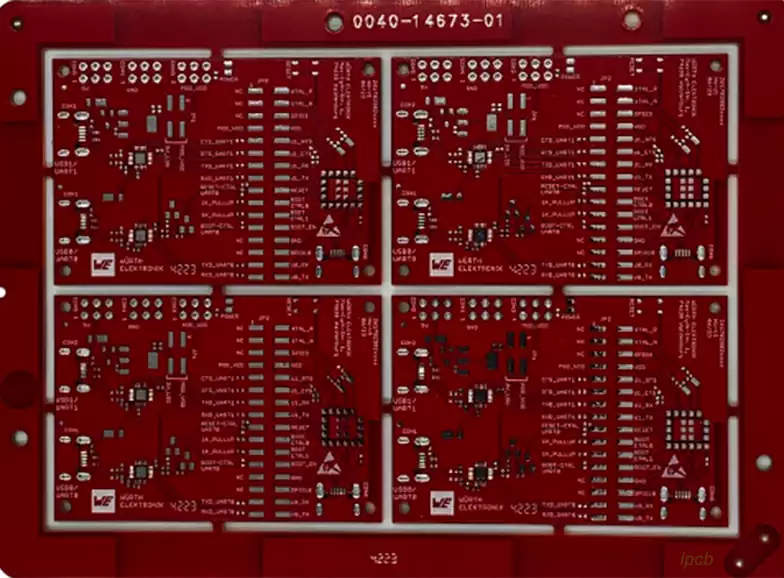

(4) For the electrical manufacturing system, regular inspection and cleaning is performed to prevent failures caused by dust and looseness.

(5) For the table and guide rails, etc., regular cleaning and lubrication to ensure the stability and accuracy of the equipment.

Printed circuit board router as one of the key equipment in the field of electronic manufacturing, with its high precision, high efficiency processing capacity and stable and reliable performance, for the quality and stability of electronic products to provide a strong guarantee. With the continuous progress of science and technology and the rapid development of electronic manufacturing industry, printed circuit board milling machine will continue to play an important role in promoting the continuous innovation and development of electronic manufacturing industry.