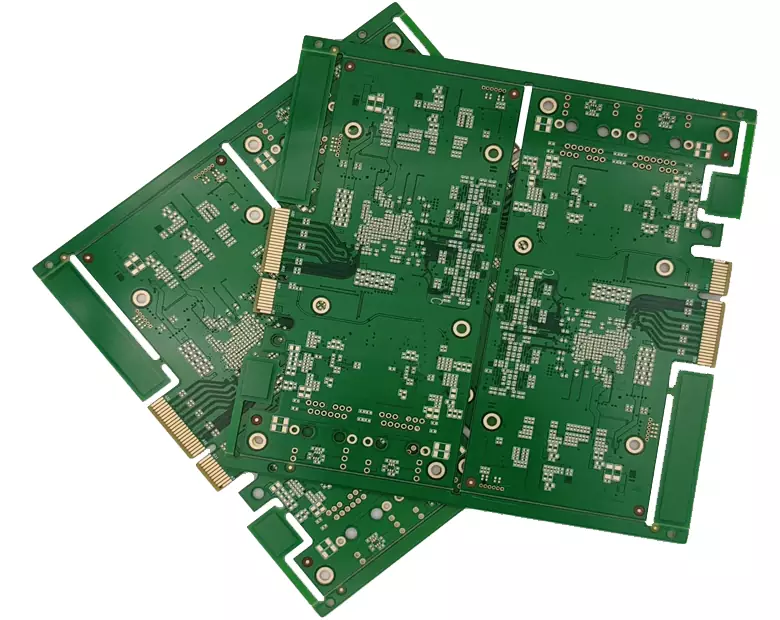

What does Quick Turn PCB mean?

Quick Turn PCB, The emphasis is on “fast”. In the electronics industry, it usually refers to a type of printed circuit board (PCB) that is quickly sampled or produced. This “speed” is reflected in the shortening of the entire process from design to production to meet the urgent time needs of customers. Quick Turn PCB services are more common in situations where design ideas need to be quickly validated, product iterations need to be carried out, or exhibition exhibits need to be manufactured in a hurry.

The characteristics of Quick Turn PCB

Timeliness: The biggest highlight of Quick Turn PCB service is its speed. Traditional PCB production may take several days or even weeks, while fast board services can be completed in a shorter period of time, such as 24 or 48 hours.

Flexibility: Due to the fact that Quick Turn PCB services are often used for small batch production or sample production, they are more adaptable to frequent design changes and demand adjustments.

Cost effectiveness: Although the unit price of Quick Turn PCB services may be relatively high, considering time costs and market response speed, its overall cost-effectiveness may be better than traditional production methods in some cases.

Application scenarios of Quick Turn PCB

PCB prototype verification: In the early stages of product development, PCB engineers need to quickly create circuit board prototypes to verify the feasibility of the design. Kuaiban service can quickly provide physical goods, helping engineers detect problems early and make adjustments.

Small batch production: For startups or small businesses, Quick Turn PCB services are a powerful tool for achieving small batch production, rapid trial and error, and market capture.

Teaching and research: In the field of education and scientific research, Quick Turn PCB can meet the needs of quickly making experimental circuit boards and accelerate research progress.

Comparison between Quick Turn PCB and standard PCB Production

Compared to traditional PCB production methods, Quick Turn PCB services place greater emphasis on speed and flexibility. Traditional production typically involves large-scale manufacturing and long cycles, while Quick Turn PCBs can complete the entire process from design to finished product in a short amount of time. Of course, this increase in speed may come at the cost of sacrificing some cost-effectiveness, but in some highly time demanding scenarios, this cost is worth it.

Quick Turn PCB price

According to the design of the circuit board, the price will be determined based on the material of the circuit board, the number of layers of the circuit board, the size of the circuit board, the quantity produced each time, the production process, small line width and spacing, small aperture and number of holes, special processes, and other requirements.

Calculate price by size: Quick Turn PCB manufacturer will provide unit prices per square centimeter based on different layers and processes of the circuit board. Customers only need to change the size of the circuit board to centimeters and multiply it by the unit price per square centimeter to obtain the unit price of the circuit board to be produced.

Calculate prices based on cost refinement: Because the raw material for Quick Turn PCB is copper-clad board, the factory that produces copper-clad board has set some fixed sizes for sale in the market, commonly 915mm * 1220mm (36 “* 48”); 940MM * 1245MM (37 “* 49”); 1020MM * 1220MM (40 “* 48”); 1067mm * 1220mm (42 “* 48”); 1042MM * 1245MM (41 “49”); 1093MM * 1245MM (43 “* 49”) Quick Turn PCB manufacturers will calculate the utilization rate of copper-clad boards for this batch of circuit boards based on the materials, layers, processes, quantities, and other parameters of the circuit boards to be produced, thereby calculating the material cost

Quick Turn PCB lead time for iPCB

The fastest time for 2-layer Quick Turn PCB is 24 hours, for 4-layer Quick Turn PCB it is 36 hours, for 6-layer Quick Turn PCB it is 48 hours, for 8-layer Quick Turn PCB it is 72 hours, and for 10-layer Quick Turn PCB it is 72 hours.

Quick Turn PCB selection recommendations

When choosing Quick Turn PCB services, attention should be paid to several key points: production cycle, quality assurance, service scope, and Quick Turn PCB price. Different Quick Turn PCB manufacturers may have differences in these aspects, so it is necessary to make the most suitable choice based on the specific needs of the project.

Quick Turn PCB is a circuit board production method that emphasizes timeliness and flexibility, especially suitable for scenarios that require Quick Turn PCB prototype verification, small batch production, or educational research. When choosing Quick Turn PCB services, multiple factors should be considered comprehensively to ensure the smooth progress of the project.