Introduction — What is Rapid PCB Prototyping?

Rapid PCB prototyping (PCB) plays a crucial role throughout the entire electronics product development lifecycle. It’s a critical step in transforming design concepts from paper into verifiable prototypes, serving as a vital bridge from concept to finished product.

Simply put, Rapid PCB Prototyping utilizes advanced manufacturing technologies and processes to produce PCB prototypes in record time for functional verification, design adjustments, and performance testing. Compared to traditional PCB manufacturing, its most significant advantage is speed, typically enabling delivery within hours or days rather than weeks. This high efficiency directly accelerates product development cycles and significantly reduces time to market.

Rapid PCB Prototyping isn’t just about saving time; it has a profound impact on the entire electronics design process: it allows engineers to iteratively test and optimize designs early in the design process, reducing the costly consequences of late-stage modifications. It also helps procurement and manufacturing teams identify potential issues early, avoiding significant risks during mass production.

In recent years, Rapid PCB Prototyping has gradually become a standard procedure in the electronics design industry. This is particularly true in high-tech industries such as consumer electronics, medical devices, automotive electronics, and aerospace. Rapid prototyping not only enhances product competitiveness but also drives innovation.

In modern electronic product development, time is of the essence. Especially in a rapidly iterating and highly competitive market, the traditional PCB manufacturing cycle often becomes a bottleneck in product development. Rapid PCB Prototyping was developed to address this efficiency bottleneck, enabling products to enter the testing and verification phase more quickly, thereby accelerating the overall development process.

Shortening Product Development Cycles

Traditional PCB production typically takes weeks or even longer, and design adjustments must wait for the entire manufacturing process to complete, causing project delays. Rapid PCB Prototyping, on the other hand, can provide prototypes within days or even hours, allowing engineering teams to more quickly verify circuit designs and identify and resolve issues. This high efficiency not only saves time but also significantly reduces the time-to-market cost.

Reducing Development Risks

Errors are inevitable during the PCB design phase. Rapid prototyping allows design teams to conduct real-world testing of PCB layout, signal integrity, and electrical performance at an early stage, thereby avoiding significant defects during mass production. This early verification mechanism significantly reduces rework and waste caused by design errors, thereby improving product reliability.

Improving Design Optimization Capabilities

Rapid PCB Prototyping enables multiple iterations. Engineers can adjust designs multiple times in a short period of time and verify the effectiveness of each change using actual prototypes. This rapid iteration capability gives design teams greater room for innovation, ensuring that the final product’s performance better meets market and user needs.

Reducing Development Costs

Although the cost of a single rapid prototyping run may be higher than the unit cost of traditional mass production, from an overall project development perspective, it significantly reduces rework and material waste caused by design errors, thereby significantly reducing total costs. Rapid prototyping offers a significant return on investment, especially in complex or high-precision PCB projects.

Supporting Cross-Departmental Collaboration

Large-scale projects require close collaboration between different departments, such as design, procurement, and production. Rapid PCB Prototyping provides a fast testing platform, helping departments synchronize progress, communicate design changes promptly, and improve collaboration efficiency.

Meeting Rapidly Changing Market Demands

Particularly in areas like consumer electronics, the Internet of Things, and smart devices, product iterations are extremely rapid, and market demands are constantly changing. Rapid PCB Prototyping can help companies quickly respond to market changes, expedite new product verification and launch, and gain a competitive edge.

In summary, Rapid PCB Prototyping is more than just a technical tool; it is an indispensable acceleration engine in the modern electronics design process. It provides strong support for design verification, iterative optimization, risk control, and market responsiveness.

Detailed Explanation of the Rapid PCB Prototyping Technical Process

Rapid PCB Prototyping is more than just a time-saving manufacturing method; it encompasses a complete set of scientific and rigorous process flows, each step of which directly impacts the quality, accuracy, and usability of the prototype. Below, we will analyze this process step by step, from design preparation, manufacturing process, to final verification.

Design Preparation and Data Processing

The first step in rapid prototyping begins with preparing the PCB design files. Engineers typically use EDA (Electronic Design Automation) software, such as Altium Designer, Cadence Allegro, or KiCad, to convert designs into production-ready files. Key tasks at this stage include:

Design Rule Checking (DRC): Ensures that routing, spacing, and hole diameters meet manufacturing specifications;

Gerber File Generation: Contains detailed information about each layer’s circuitry and is essential data for PCB manufacturing;

NC Drill File Generation: Defines hole location, diameter, and type;

Assembly Files (if required) are added to facilitate subsequent assembly and testing.

The accuracy of design preparation directly impacts the efficiency and accuracy of subsequent rapid prototyping, so this step requires exceptional care.

Rapid Prototyping Material Selection

Different types of PCB prototypes require different material choices. Common materials include FR-4, Rogers high-frequency materials, and flexible materials. Key factors in material selection include:

Performance requirements: Signal integrity and temperature resistance; Processability: Suitability for rapid manufacturing; and Cost: The cost of rapid prototyping must be balanced with budget.

The choice of materials directly determines the performance and production difficulty of the prototype, making it a crucial step in rapid prototyping.

Manufacturing Process

The core of rapid PCB prototyping lies in accelerating the manufacturing process. This typically relies on advanced processing equipment and techniques, including:

Laser engraving and cutting: Rapidly create high-precision circuit patterns, reducing the time required for traditional chemical etching;

Rapid drilling: Using CNC drilling machines to efficiently complete drilling tasks;

Copper plating and etching: Forming the metal layers of the circuits and completing the basic PCB structure;

Rapid lamination: The production of multi-layer boards requires efficient lamination technology to ensure stable connections between layers;

Surface treatments such as HASL and ENIG improve solderability and oxidation resistance.

These processes, combined with advanced automated equipment, significantly reduce the time required for rapid prototyping compared to traditional production.

Assembly and Testing

Rapid prototyping encompasses not only PCB manufacturing but also the necessary assembly and testing. The main steps are:

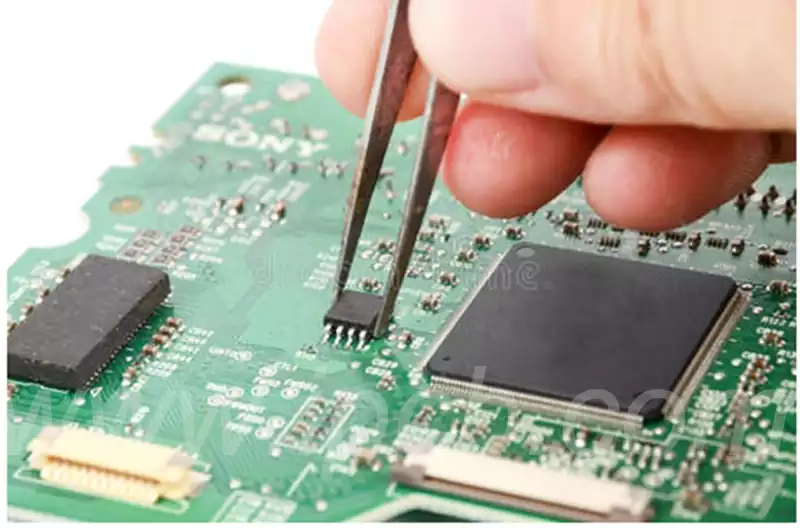

Surface mount and plug-in components: Assemble according to design requirements;

Functional testing: Verify circuit functionality meets design goals;

Signal integrity testing: Ensure high-frequency signal transmission is normal without interference or loss.

The assembly and testing phase is the final step in rapid prototyping, ensuring that the prototype not only looks right but also functions properly.

Feedback and Iteration

The advantage of Rapid PCB Prototyping lies in its speed of iteration. After testing is complete, the engineering team adjusts the design based on the results and quickly moves on to the next round of prototyping. This closed-loop process significantly improves product development efficiency.

This technical process demonstrates that Rapid PCB Prototyping is not just a simple manufacturing step, but a complete closed loop encompassing design, manufacturing, testing, and feedback. Its core value lies in shortening development cycles while ensuring high accuracy and reliability.

Key Factors in Material and Process Selection

In Rapid PCB Prototyping, the choice of materials and processes directly determines the performance, manufacturing difficulty, and cost of the prototype, making them a core component of the entire rapid prototyping process. When selecting materials and processes, designers and engineers need to consider multiple factors to ensure the most efficient prototyping while ensuring quality.

PCB Substrate Material Selection

Substrate materials serve as the backbone of the PCB, and different materials have varying physical, electrical, and mechanical properties. Common substrate materials for rapid prototyping include:

FR-4: The most common PCB substrate material, it offers excellent mechanical strength and good electrical performance, making it suitable for most rapid prototyping needs at a low cost.

High-frequency materials (such as Rogers and PTFE): Suitable for high-speed signals, RF, and microwave circuits, maintaining good signal integrity, but are more expensive and challenging to process.

Flexible materials (such as PI film): Suitable for rapid prototyping of flexible printed circuits (FPCs), enabling specialized designs such as bending and folding, but requiring complex processing.

When selecting a substrate material, it is important to consider the application’s technical requirements, signal transmission characteristics, and cost budget.

Copper Thickness Selection

Copper thickness directly affects the PCB’s current-carrying capacity, thermal management capabilities, and cost. Common copper thicknesses used in rapid prototyping include:

1oz/ft² (35μm): Suitable for most general circuits; 2oz/ft² (70μm) and above: Suitable for circuits with high current demands or high heat dissipation requirements; Custom copper thicknesses may be required for high-speed signals and special applications.

The selection of copper thickness should be considered in conjunction with the design current, thermal management requirements, and cost.

Surface Treatment

Surface treatment in rapid prototyping not only affects solderability but also circuit reliability. Common surface treatment methods include:

HASL (Hot Air Leveling): Low cost, suitable for general rapid prototyping, but with poor flatness; ENIG (Immersion Gold Ingot): Excellent solderability and oxidation resistance, suitable for high-precision PCBs, but with a higher cost; OSP (Organic Overprint Surface): Environmentally friendly and suitable for multiple soldering cycles, but with a limited shelf life.

Selecting the appropriate surface treatment requires consideration of the prototyping cycle, soldering process, and operating environment.

Number of Layers and Structure

The more layers there are, the more complex the PCB design and the more difficult it is to manufacture. For rapid prototyping, a fewer number of layers is often preferred to speed up production. However, for high-performance, multi-functional products, multi-layer rapid prototyping is still necessary. Engineers need to balance functional requirements and prototyping efficiency:

Single-layer/double-layer boards: Fast processing, low cost, suitable for simple circuit verification; multi-layer boards: Suitable for complex designs such as high-speed signal processing and EMI suppression, but with longer manufacturing cycles.

Processing Process Selection

In addition to materials, the processing technology for rapid prototyping is also crucial. Common processes include:

CNC milling: Suitable for small-batch rapid prototyping, with high flexibility, but relatively low efficiency; Laser Direct Writing (LDW): No mold required, suitable for complex designs, and fast speed; Rapid Chemical Etching: Low cost, suitable for large-area circuits, but with limited accuracy.

The choice of different processes requires a comprehensive evaluation based on the structural complexity, precision requirements, and cost of the PCB.

Cost and Time Trade-off

Rapid prototyping emphasizes speed, but speed often comes with increased costs. The selection of materials and processes must strike a balance between time, cost, and performance. Engineers should prioritize faster prototyping, lower cost, or higher performance based on the project stage and goals.

In summary, the choice of materials and processes is not just a technical issue; it’s also a strategic decision. Appropriate selection can significantly improve the efficiency and success rate of Rapid PCB Prototyping.

Applications of Rapid PCB Prototyping in Various Industries

The value of Rapid PCB Prototyping lies not only in the technology itself, but also in its profound impact on product development speed and quality across various industries. It has been widely adopted in a variety of fields, from consumer electronics to aerospace, and plays a key role in each. Below, we will analyze its practical applications and advantages in each field.

Consumer Electronics

The consumer electronics industry experiences an extremely rapid product upgrade cycle, and the market demand for innovation and functionality is growing. Rapid PCB Prototyping can help companies quickly verify new product designs, shorten development cycles, and seize market opportunities.

For example, in products such as smartphones, wearable devices, and smart home devices, PCB designs are highly complex and have strict requirements for size, signal integrity, and cost. Rapid prototyping can provide prototypes within a few days, helping engineers identify design flaws early, optimize circuit layouts, and reduce risks during mass production.

Automotive Electronics

With the development of smart cars and autonomous driving technology, automotive electronic systems are becoming increasingly complex. Rapid PCB prototyping plays a vital role in automotive electronics development, particularly in the design and verification of key components such as electronic control units (ECUs), sensors, and radar systems.

Rapid prototyping not only shortens R&D cycles but also helps engineers conduct functional testing and durability verification under real-world operating conditions. This is crucial for improving the safety and reliability of automotive electronics.

Medical Devices

Medical devices place extremely high demands on the reliability and precision of electronic circuits. Rapid PCB prototyping enables early design verification, ensuring circuit stability in complex environments and reducing the risk of device failure.

For example, portable diagnostic devices, ECG monitors, and surgical robots often require multiple iterations of testing to meet stringent medical standards. Rapid prototyping can accelerate this process, improving product market responsiveness while reducing development risks.

Communications Equipment

Communications equipment, especially high-speed and high-frequency devices, places extremely high demands on PCB performance. Rapid PCB prototyping enables rapid verification of PCB performance in high-frequency signal transmission, EMI suppression, and thermal management. In the development of products such as wireless base stations, optical communication modules, and 5G RF modules, rapid prototyping helps engineers perform signal integrity analysis and structural optimization, ensuring that products meet complex communication requirements.

Aerospace

Electronic systems in the aerospace sector require extremely high reliability and precision. Rapid PCB prototyping is primarily used in this field for verification and functional testing of high-reliability electronic modules.

For example, in satellites, drones, and flight control systems, any circuit defect could pose a significant safety risk. Rapid prototyping provides a valuable tool for aerospace applications.Aerospace engineers are provided with an efficient verification platform, enabling designs to be repeatedly optimized in a short period of time, ensuring system safety.

Industrial Automation

Industrial automation equipment often requires long periods of operation under high load, placing high demands on PCB durability and stability. Rapid PCB Prototyping can verify the performance of industrial equipment control boards, driver boards, and other components early in the design process, reducing the risk of later failures.

For example, in industrial robot control systems, PLC control boards, and automated testing equipment, rapid prototyping can help engineers identify potential issues early and optimize them, ensuring long-term stable operation.

Emerging Technology

Rapid prototyping is particularly important in emerging fields such as the Internet of Things (IoT), artificial intelligence (AI), and wearable technology. Due to the rapid pace of technological advancement in these fields, product development cycles must be extremely short.

Rapid PCB Prototyping provides startups and technical teams with the ability to quickly verify and iterate, enabling them to quickly launch product prototypes and verify commercial viability in highly competitive markets.

In summary, Rapid PCB Prototyping has a wide range of applications. While the needs of different fields vary, the efficiency improvements, risk reduction, and cost control brought about by rapid prototyping are universally applicable. It has become an indispensable component in driving the development of modern electronic products.

Challenges and Future Trends of Rapid PCB Prototyping

Although rapid PCB prototyping offers significant advantages in accelerating electronic product development, reducing costs, and improving design verification efficiency, it still faces numerous challenges in practical application. At the same time, with technological advancements and changing industry needs, this field is constantly evolving, demonstrating many noteworthy future trends.

Challenges

Technical Challenges of High Precision Requirements

As electronic products move toward higher frequencies, higher densities, and higher complexity, PCB prototypes are increasingly demanding in terms of precision. Rapid PCB prototyping requires achieving high-precision manufacturing within a short timeframe, placing higher demands on existing processing equipment and processes. High-precision processing often comes with higher costs and more complex processes, creating a conflict between technology and efficiency in rapid prototyping.

Material and Process Limitations

Limitations in material selection and processing remain major bottlenecks in rapid prototyping. Special materials such as high-frequency substrates and flexible materials struggle to achieve the perfect balance between performance and processing speed in rapid prototyping. Furthermore, certain advanced processes (such as HDI and multilayer board processing) are costly and time-consuming for rapid prototyping, limiting their widespread adoption.

Cost Pressure

While rapid prototyping offers time advantages, high-precision materials, advanced processing equipment, and small batch production all increase unit costs. For startups and small and medium-sized enterprises with limited budgets, finding a balance between rapid prototyping and cost is a real challenge.

Complexity of Testing and Verification

Rapid prototyping requires not only rapid PCB production but also efficient testing and verification. As circuit complexity increases, the testing process becomes more complex, posing challenges to the overall efficiency of rapid prototyping.

Future Trends

Automation and Intelligence

In the future, rapid PCB prototyping will rely more heavily on automated processing and intelligent manufacturing. Advanced CNC machines, laser direct writing equipment, and automated assembly lines will significantly shorten production cycles and improve processing accuracy. The application of artificial intelligence (AI) and machine learning in design optimization and manufacturing process control will also drive rapid prototyping into an intelligent phase.

The Popularization of High-Performance Materials

With the advancement of materials science, more high-performance materials will enter the rapid prototyping market, such as low-loss high-frequency materials and flexible/rigid-flex materials. These materials not only meet the needs of high-frequency signal transmission and specialized applications, but will also drive rapid prototyping towards more complex and advanced technologies.

Cloud Manufacturing and Digital Design

The rise of cloud manufacturing platforms will make rapid PCB prototyping more convenient. Designers can upload design files via the cloud and connect directly to the manufacturing plant for real-time monitoring of production progress and quality. This will greatly improve cross-regional collaboration efficiency and shorten product development cycles.

Diversification and Customization

In the future, rapid prototyping will become even more personalized, meeting the customized needs of different customers and projects. In emerging fields such as the Internet of Things, wearable devices, and medical electronics, rapid prototyping will become a crucial tool for accelerating innovation.

Green Manufacturing Trends

Environmental protection requirements and sustainable development will drive rapid prototyping to adopt more environmentally friendly materials and processes, such as lead-free soldering, green chemical etching, and energy-saving processing. This not only complies with industry standards but also helps enhance a company’s image of social responsibility.

In summary, despite the challenges facing Rapid PCB Prototyping, technological advancements, material innovations, and changes in manufacturing models will drive its continued development, making it an indispensable core component in future electronic product development.

Summary

Rapid PCB Prototyping has become a key engine for modern electronic product development. It not only significantly shortens the product design and verification cycle, but also effectively reduces development costs and risks. In a highly competitive market, rapid prototyping helps companies respond more quickly to demand and accelerate innovation.

However, this technology is not without its flaws—high precision requirements, material and process limitations, cost pressures, and testing complexity are all challenges that the industry must face. In the future, automation, intelligent manufacturing, the application of high-performance materials, the widespread use of cloud manufacturing platforms, and the integration of green manufacturing concepts will bring new development opportunities for Rapid PCB Prototyping.

It is foreseeable that with continued technological advancement, Rapid PCB Prototyping will be deeply applied in more fields, becoming a core driving force for innovation and development in the electronics industry. From consumer electronics and automotive electronics to aerospace and medical equipment, the value of rapid prototyping will become increasingly prominent. For technicians, procurement engineers, and newcomers to the industry, mastering this technological trend will not only enhance product competitiveness but also help them gain a leading position in the industry.