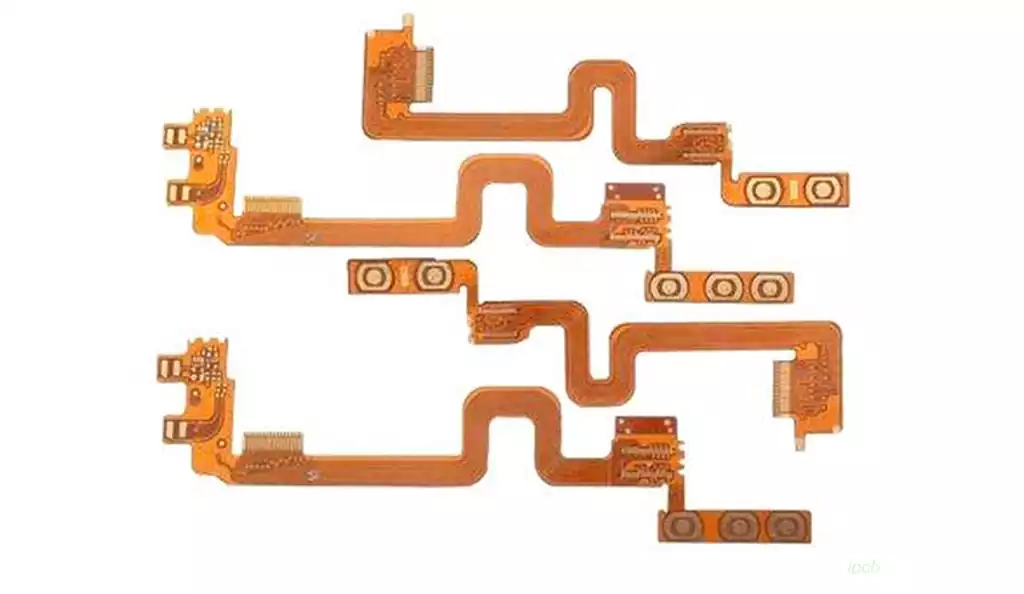

Reflow soldering is a soldering process in which a solder joint is formed by re-melting a pre-placed solder without adding any additional solder during the soldering process. An auxiliary tool used in reflow soldering is the reflow carrier, which is an auxiliary tool used in the SMT reflow soldering process and is also known as a reflow oven carrier or fixture. Its main role is to carry and fix the circuit board or other electronic components in the electronic manufacturing process, so that it can smoothly pass through the reflow soldering furnace, to ensure the quality and efficiency of soldering.

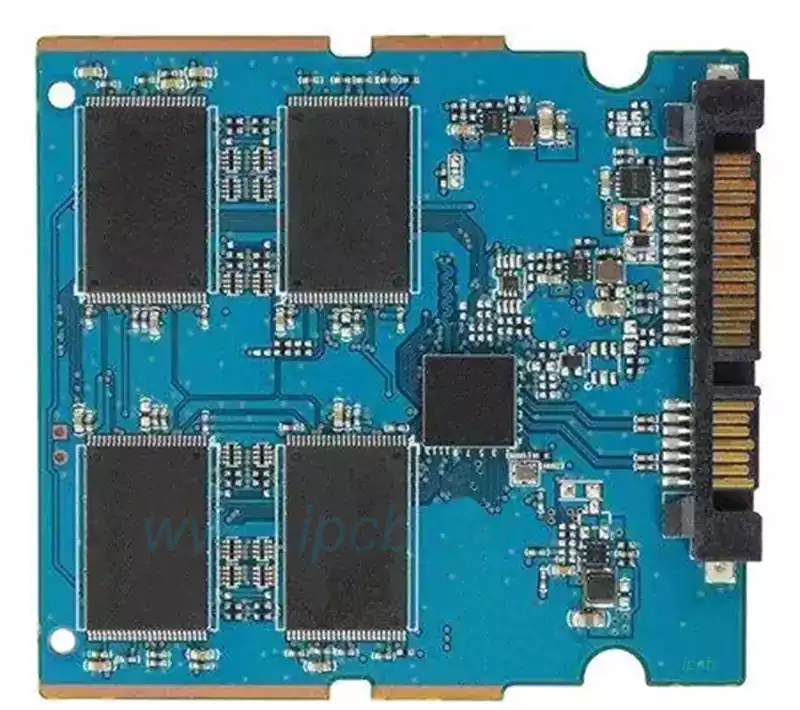

Reflow soldering plays an important role in the SMT process. In the SMT process, the main application of reflow soldering is to put the circuit boards with components pasted on them into the track of the reflow soldering machine and go through the process of heating, holding, soldering and cooling. During this process, the solder paste changes from paste to liquid through high temperature, and then becomes solid through cooling, thus realizing the soldering of SMD electronic components and PCB boards.

The role of the reflow soldering frame in the reflow soldering is crucial. During the soldering process, the reflow rack carries and holds the board, ensuring that it passes smoothly through the reflow oven. Through the use of reflow racks, can avoid the printed circuit board in the transmission process of deformation, displacement and other problems, thereby improving the quality and efficiency of welding. At the same time, the design of the reflow soldering frame can also reduce the interference of reflected waves in the soldering process and improve the quality of signal transmission.

Secondly, the reflow soldering frame process design needs to be customized according to the specific welding requirements and board size. The design needs to fully consider the shape, size, component distribution, and other factors of the circuit board to ensure that the reflow bracket can accurately fix the circuit board and keep it stable in the transmission process. In addition, the reflow bracket material selection is also very critical, need to have high temperature, corrosion resistance, and other properties to adapt to the soldering process of high temperature and corrosive environment.

In the reflow soldering process, the reflow soldering frame plays an important role. First, the circuit board is placed in the reflow rack, and accurate positioning and fixation. Then, the reflow rack is fed into the reflow oven for soldering. During the soldering process, the reflow rack needs to withstand the high temperature environment and remain stable to ensure that the circuit board will not be deformed or shifted. Finally, the reflow racks and boards are cooled and inspected after the soldering process is completed to ensure the quality and reliability of the soldering.

Reflow carrier plays an important role in reflow soldering. Through reasonable design and use, can improve the quality and efficiency of welding, reduce production costs and time.