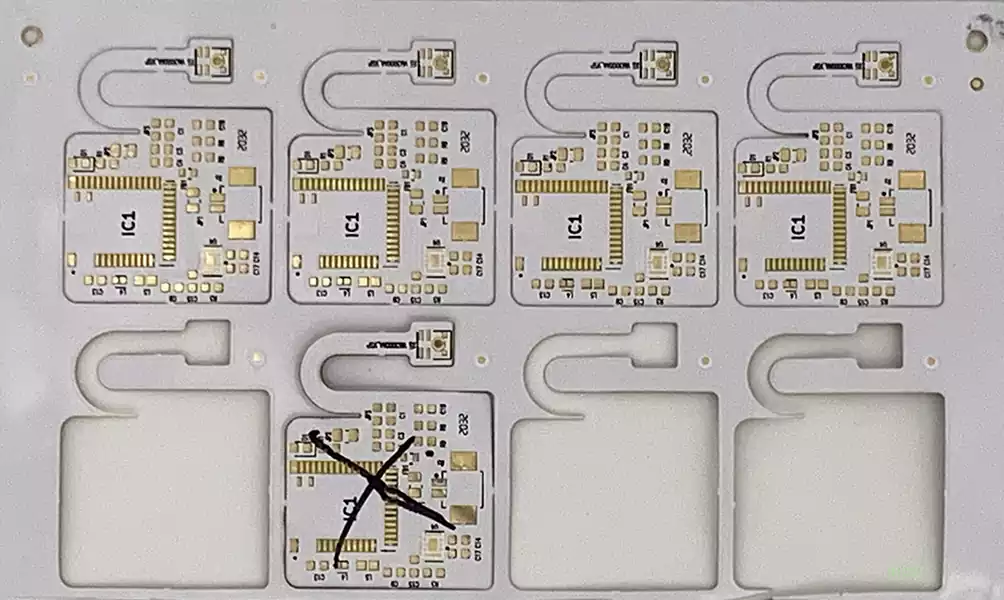

Rogers pcb substrate, using the proprietary amide resin material developed by Rogers, this material gives it excellent dielectric properties, thermal stability and mechanical strength.

Even under extreme working environments such as high temperature and high humidity, high frequency and high speed, Rogers PCB boards are able to maintain stable operation, demonstrating their strong adaptability and reliability.

Rogers PCB board of the significant characteristics of the elaboration

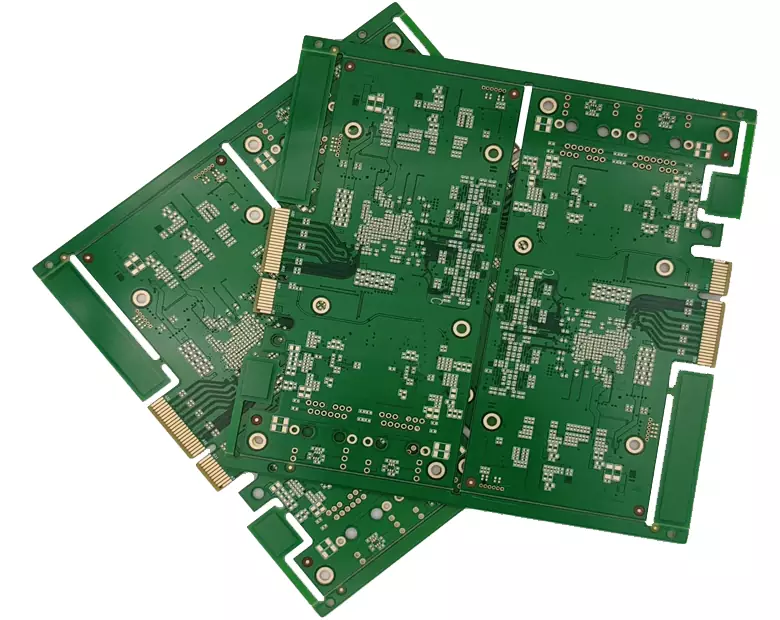

excellent dielectric performance: Rogers PCB board using a special amide resin material, this innovation makes its dielectric constant, loss factor and leakage current and other key parameters have shown great stability. This feature is essential to meet the needs of high-precision, high-speed circuit design, to enhance the overall performance of electronic equipment to lay a solid foundation.

significant thermal stability advantage: Rogers PCB board in the thermal stability of outstanding performance, its low coefficient of thermal expansion (CTE) to ensure that the high temperature and high humidity environment can still maintain stable performance. This feature effectively avoids circuit failure problems caused by temperature changes, thus guaranteeing the continuous and stable operation of the circuit system.

excellent mechanical strength characteristics: Rogers PCB boards are made of hard and durable materials that can withstand large mechanical loads. This feature ensures that the circuit in a variety of complex working conditions can maintain reliable operation, for the stable operation of the entire electronic system provides strong support.

Rogers PCB board production process features

- Plate cutting process: In view of the special materials used in Rogers PCB boards, the cutting process requires the use of high-precision cutting technology to ensure that the size and shape of the plate fully meet customer requirements.

- Surface treatment process: In order to ensure the cleanliness and adhesion performance of the board surface, we use special chemicals and processes for surface treatment. This process can effectively remove the oxides on the surface and improve the bonding between the sheet and the subsequent process materials.

- Coating process: The surface of Rogers PCB board needs to be coated with a layer of copper foil to enhance its conductivity. We adopt electroplating or wet coating process to ensure the uniformity and adhesion of copper foil.

- drilling process: In order to meet the complex wiring needs in the circuit board, we use a high-speed plating process to open holes. This process can accurately control the hole diameter and hole spacing to ensure the accuracy and reliability of the circuit board.

- copper plating process: in the circuit layer production process, we use electrolytic copper plating technology, strict control of the thickness and uniformity of the copper layer. This helps to improve the conductivity and stability of the circuit board.

- line graphics drawing process: according to customer demand, we can choose to silkscreen, inkjet printing, topography and other ways to draw the line graphics. These processes can ensure the clarity and accuracy of the line graphics.

- Finished product test link: In the final stage of production, we will carry out strict finished product test on Rogers PCB board. Tests include silkscreen quality, line through the situation, electrical performance tests, etc., to ensure that the quality and performance of the product to meet customer requirements.

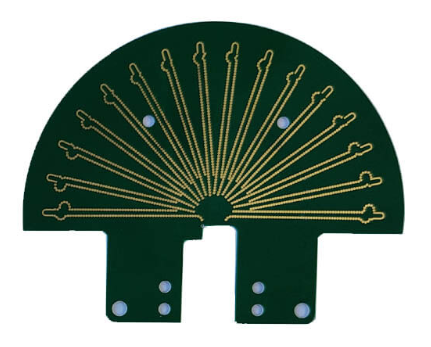

the Rogers PCB board of multi-disciplinary applications

Rogers PCB boards are widely used in many fields due to their unique performance and stability. The following are a few major application areas:

1) the field of communication technology: Rogers PCB Substrate play an important role in communication equipment, such as high-frequency antennas, base station antennas and so on. Its stable dielectric properties and excellent thermal stability ensure the efficient operation of communication equipment in complex environments.

2) Military and aviation field: In the field of military aviation, Rogers PCB is widely used in radar, satellite, missile and other key equipment. Its high-strength and high-temperature-resistant characteristics enable these devices to maintain stable operation under extreme conditions, providing strong support for the national defense cause.

3) Medical equipment field: In the field of medical equipment, Rogers PCB board also plays an indispensable role. It is used in medical monitoring instruments, pacemakers, MRI and other equipment, and its high stability and reliability ensure the accuracy and safety of medical equipment.

4) Automotive electronics field: With the continuous development of automotive electronics technology, Rogers PCB boards are also widely used in car navigation, audio, body control and other aspects. Its excellent mechanical strength and thermal stability enable the automotive electronic system to run stably in the complex and changeable vehicle environment, enhancing the safety and comfort of the car.

Above is the rogers pcb substrate share brought by Mia, thanks for watching.