The HF plate Rogers-rO4003C is a patented glass fabric reinforced hydrocarbon resin system/ceramic filler material with electrical properties very close to those of PTFE/prepared glass fabric materials and processability similar to epoxy/glass fabric materials. The sheet offers tightly controlled dielectric constant and loss at a fraction of the price of conventional microwave materials and can be used without special plating through-hole pre-treatment or handling procedures. It is available in two different types of glass cloth, 1080 and 1674, all meeting the same electrical specifications for the laminate.

RO4003C laminates are available in two different configurations with different glass cloths 1080 and 1674. All configurations have the same electrical performance specifications. RO4003C laminates are subjected to stringent process controls, the material has a consistent dielectric constant (Dk) and low loss characteristics, and its mechanical properties make it identical to standard epoxy/glass processes at a much lower cost than traditional microwave laminates. Unlike PTFE microwave materials, this material requires no special through-hole processing or handling procedures.

Product Characteristics of Rogers RO4003C:

Relative permeability (Ɛr), also known as dielectric constant (Dk), is 3.55;

Dielectric loss angle tangent: 0.0027@10GHz/23°C;

Standard epoxy/glass cloth processing is possible;

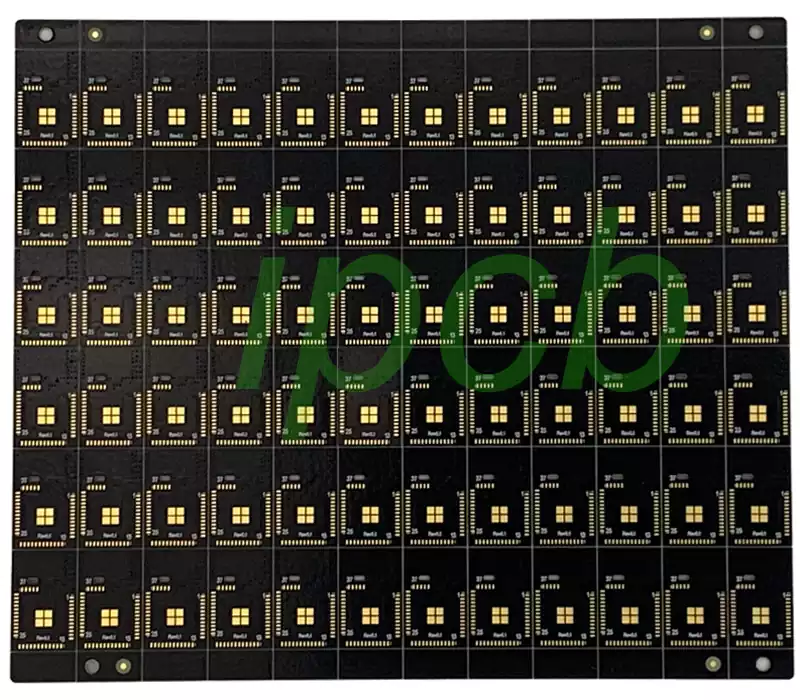

Number of layers: 6 layers

Board thickness: dielectric thickness 0.762MM, circuit board finished thickness 1.6MM ;

Copper thickness: base copper 0.5OZ, finished copper thickness 1OZ;

Surface technology: immersion gold;

Uses: radio backhaul, communication systems, high-speed computing, IP infrastructure, power amplifiers, small base stations/distributed antenna systems (DAS), test and measurement

Advantages of Rogers RO4003C:

Excellent electrical properties:

The electrical properties are very close to those of PTFE/glass cloth materials, with a very stable dielectric constant and low dielectric loss. This characteristic allows it to excel in high-frequency applications, ensuring the accuracy and integrity of signal transmission.

Excellent processability:

Processability is similar to epoxy/glass cloth materials, which means it can be manufactured using standard epoxy/glass cloth processing. This not only increases productivity, but also reduces production costs.

Stable mechanical properties:

It has excellent mechanical properties with a coefficient of thermal expansion similar to that of copper. This match in coefficient of thermal expansion reduces dimensional changes due to temperature variations and provides excellent dimensional stability, which is critical for the manufacture of precision circuit boards and microwave components.

Cost-effective:

Particularly suitable for multilayer board (MLB) structures. Compared to conventional FR-4 materials, this sheet offers superior performance, especially in high-frequency applications, although its processing is similar. This makes it a cost-effective option that can meet performance requirements while reducing overall costs.

With its unique material properties and superior performance, Rogers RO4003C has become a leader in high-frequency circuit board design for a wide range of applications. Looking ahead, we are confident that it will continue to lead the way in HF circuit board material innovation and bring more possibilities to the industry.