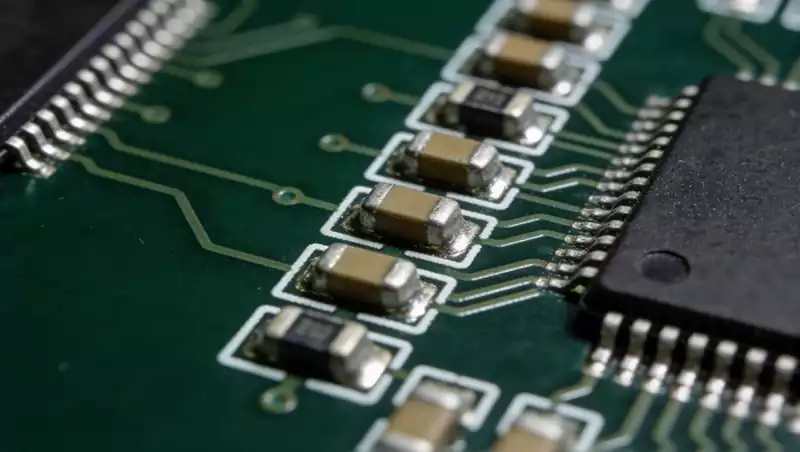

Semiconductor base material is an indispensable component in the development of contemporary advanced manufacturing, which is widely used in the production of various electronic devices such as transistors, light-emitting diodes and solar cells. In the manufacturing process of semiconductor products, selecting the right substrate is a crucial part of the process, as the quality of the substrate will have a direct impact on the quality and stability of the final product.

When selecting a semiconductor substrate, a number of aspects need to be considered, including the physical properties of the material, electrical properties, cost-effectiveness, and manufacturing process. There is a wide range of semiconductor substrate materials available in the market, such as silicon, sapphire, silicon carbide, gallium nitride, and so on. In order to ensure the stability and performance of electronic devices, different types of semiconductor materials require substrate materials that are compatible with them.

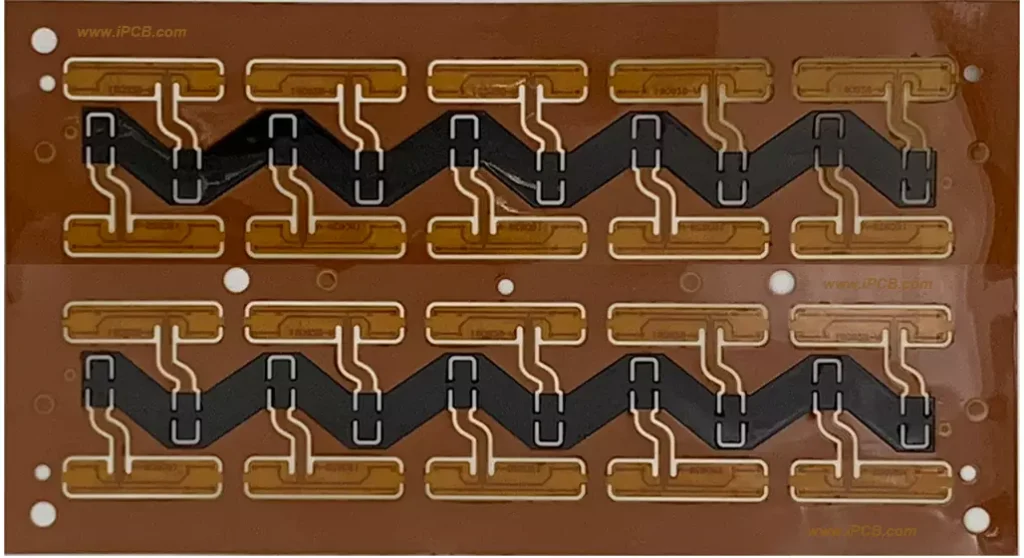

Glass substrate is a kind of substrate using glass as the main constituent material, which is not a complete replacement of the entire substrate, but replaces the organic material part of the traditional package. The current mainstream glass substrate types include soda-lime glass and high alumina glass, the former by adding calcium oxide and sodium oxide and other elements within the silica matrix made of simple formulas and low technical difficulties; the latter is integrated into the basic glass composition of alumina, which can significantly improve the strength of the glass and reduce the difficulty of strengthening the processing, but because of its complex formulations and manufacturing processes, the global mastery of this technology enterprise However, due to its complex formulation and manufacturing process, the number of companies that have mastered this technology worldwide is limited.

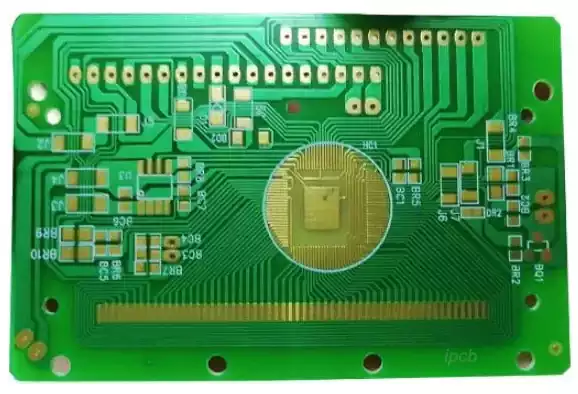

Glass substrates offer a number of significant advantages over traditional organic substrate materials. It has excellent thermal conductivity and thermal stability, can effectively dissipate heat and reduce the operating temperature of the chip, thereby enhancing the reliability and service life of the chip, which is particularly important for high-performance chips, because such chips will generate a lot of heat during operation, putting forward higher requirements for thermal management. The glass pcb also has high transparency and excellent optical uniformity, giving it good optical properties for optical measurements. In addition, its high density of vias, extremely low flatness, and excellent mechanical stability allow it to achieve finer line width and line spacing control, increasing interconnect density up to 10 times that of the original, helping to integrate more functionality on the same chip, and thus increasing computing speed and energy efficiency.

Despite its superior performance, glass pcb is still facing problems such as fragility, immature glass perforation technology, and warpage caused by thermal stress.In response to these problems,many scholars in China have proposed a variety of solutions for reference. For the fragility problem,we can start from the material itself,by adding trace elements to change the mechanical properties of the glass or adjust the manufacturing process to optimise the material properties;or develop new equipment processes, use other materials or change the production process to provide protection. For the thermal stress warpage problem,the degree of warpage can be reduced by increasing the thickness of the glass pcb,partitioning the stacked film sufficiently to release surface stress, and making the coefficient of thermal expansion (CTE) of the glass substrate close to the CTE of the stacked film.

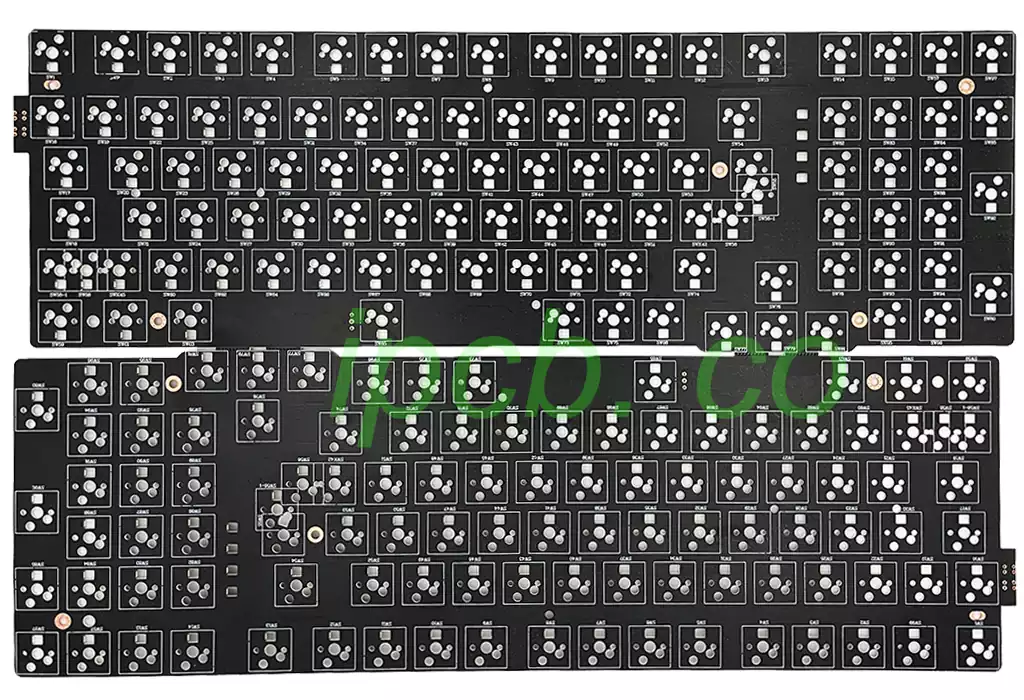

Strong connection between semiconductors and glass pcb

In the production of semiconductor products,glass pcbs are widely adopted in the manufacturing of transistors,solar cells,and other components. Compared to other substrate materials,glass pcb stands out for their excellent surface smoothness and outstanding dimensional stability.At the same time, its coefficient of thermal expansion is close to that of silicon,a feature that effectively mitigates the effects of thermal stress.

In addition, glass pcb exhibits excellent optical transparency,which is essential for improving the efficiency of photovoltaic conversion devices. By depositing appropriate metal films on glass substrates,we can create photovoltaic cell modules that are widely used in scenarios such as solar power stations and home photovoltaic systems.

Semiconductors and glass substrates are inextricably linked.In the field of semiconductor manufacturing,glass pcbs play an irreplaceable role, providing a solid foundation for the performance and stability of electronic products.With the continuous progress and optimisation of semiconductor technology, glass substrates have a great potential for future applications and a promising future.