Principles of Electronic Component Selection

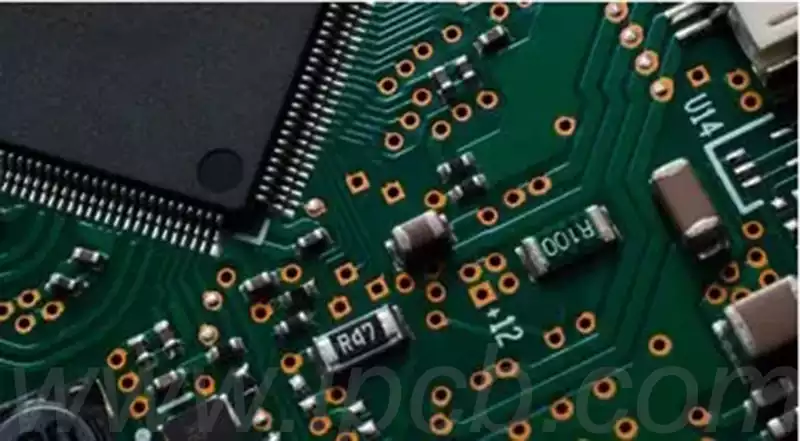

Performance and Reliability First

When selecting electronic components, performance and reliability are the primary considerations, covering electrical characteristics, temperature range and voltage resistance. Key components, such as processors and memories, should be reliable products of well-known brands and proven in the market to ensure product stability and improve overall performance.

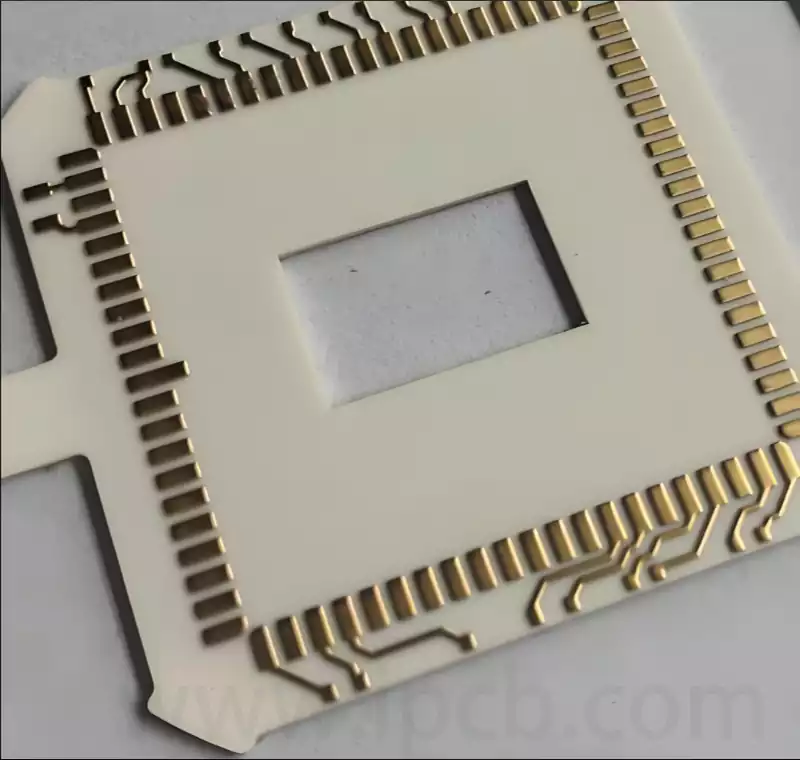

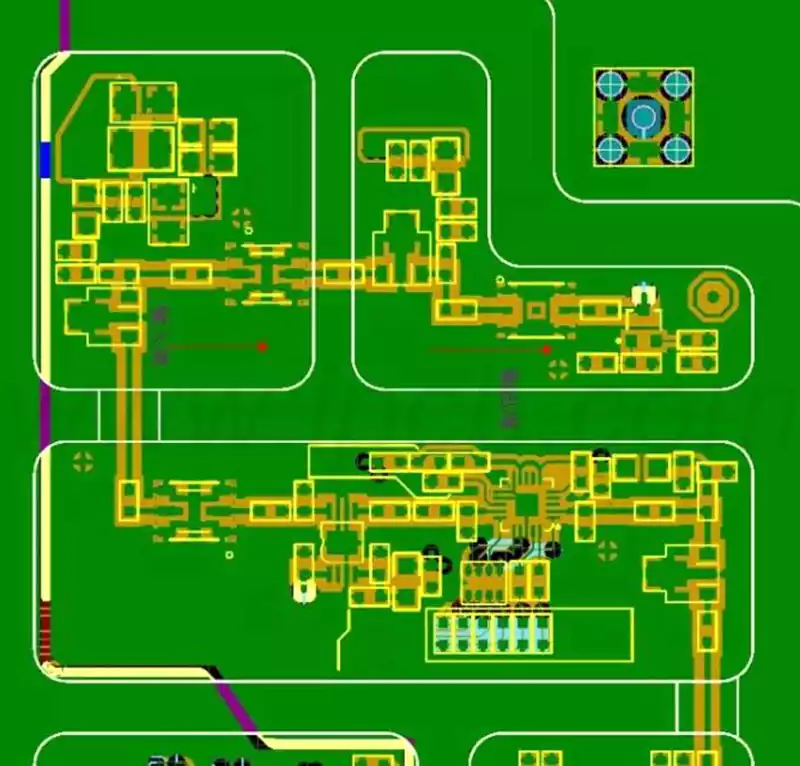

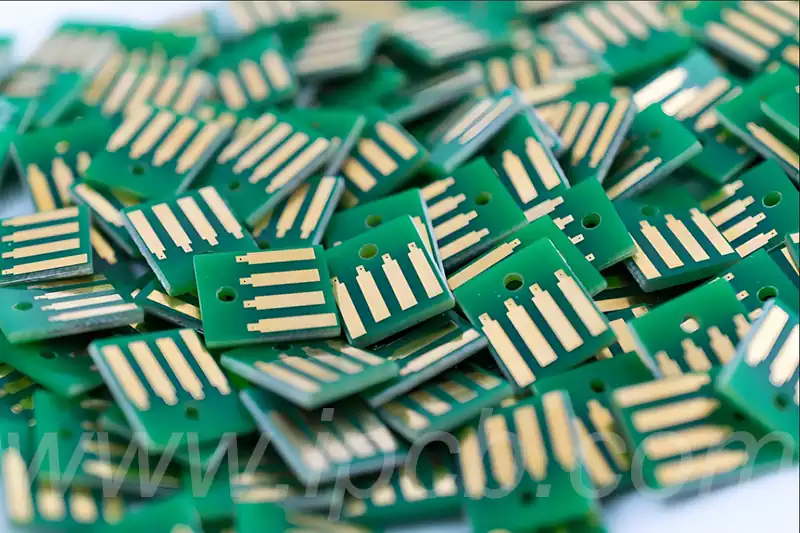

Appropriate Packaging and Size

The package and size of electronic component directly affect the PCB design and the ease of SMD processing. Under the premise of meeting the performance requirements, priority should be given to the use of small size and simple package components to facilitate high-density mounting, improve production efficiency, and reduce the board area to reduce costs.

Cost and supply stability

Cost is a key factor in the procurement process, need to meet the performance requirements under the premise of selecting cost-effective components. At the same time, consider the stability of the supply of components to avoid production impacts due to stock-outs or price fluctuations. Establishing long-term supplier relationships will ensure a stable supply chain.

Compatibility and replaceability should not be ignored

When selecting electronic components, consider their compatibility with existing or future products. Meanwhile, in order to cope with supply chain problems, the interchangeability of components should be considered, i.e. whether they can be replaced by other brands or models, so as to minimise supply risks.

Environmental and safety standards need to be complied with

As environmental awareness rises, it is increasingly important to select electronic components that comply with environmental standards. Priority should be given to components made of lead-free, halogen-free and other environmentally friendly materials, and to ensure compliance with relevant safety standards, such as UL, CE and other certification requirements, in order to enhance the competitiveness of the product market.

PCB substrate selection principles

Material properties and types need to match

PCB substrates are divided into two categories: organic and inorganic. When selecting, need to consider the electrical properties, thermal stability, mechanical strength and other factors. Such as FR-4 materials for high-frequency and high-speed circuits, while CEM-1 and FR-1 are suitable for occasions with low performance requirements.

Size and thickness need to be moderate

The size of the substrate needs to meet the needs of the circuit design, while taking into account the material utilisation and cost-effectiveness. Thickness needs to strike a balance between performance and cost, ensuring mechanical support and electrical performance while controlling cost and weight.

Appropriate temperature and humidity resistance

According to the environment in which the product is used, choose the substrate with appropriate temperature and humidity resistance to improve product reliability and service life.

Processability and environmental friendliness

Select substrates that are easy to cut, drill, plating and other processing to improve production efficiency. At the same time, select substrates that meet environmental standards, such as halogen-free substrates, to meet environmental requirements.

Cost and supply stability should be considered

Under the premise of meeting performance requirements, select cost-effective substrates and consider the stability of supply to ensure that production is not affected. Establishing partnerships with multiple suppliers can reduce supply risk.