In the field of electronic product manufacturing, solder contamination on PCB gold fingers is a common and challenging issue that significantly impacts product performance and reliability. Especially during critical processes such as solder paste printing and reflow soldering, even minor operational errors or environmental factors can cause solder paste to accidentally adhere to the gold fingers, thereby affecting the quality of the final product. Therefore, gaining a thorough understanding of the causes of solder adhesion on gold fingers and mastering effective handling and preventive measures are of great significance for improving manufacturing yield and reducing production costs in electronic manufacturing.

Causes of solder adhesion on pcb gold fingers

During electronic manufacturing, particularly in the solder paste printing process, due to improper operation or negligence, tiny solder paste particles may adhere to the gold fingers, or solder powder may directly settle on their surfaces. Additionally, during manual operations, solder powder on the hands may inadvertently come into contact with the gold fingers. These solder points may not be noticeable before reflow soldering, but after being melted by high-temperature reflow, they will clearly remain on the gold fingers.

Methods for addressing solder adhesion on pcb gold fingers:

Increase the width of the gold fingers: If solder adhesion on the gold fingers is severe, try increasing the width of the gold fingers. This can enhance the adhesion of solder paste on the gold fingers’ surface, thereby improving soldering success rates.

Adjust the viscosity of the solder paste: The higher the viscosity of the solder paste, the more difficult it is for the paste to flow smoothly when coating the gold fingers, leading to incomplete coverage. You can try adjusting the viscosity of the solder paste to make it more fluid and better cover the gold fingers’ surface.

Improve printing accuracy: During the printing process, if the distance between the PCB and the screen is insufficient, or if the pressure of the screen is insufficient, it will affect the printing accuracy and cause solder to adhere to the pcb gold fingers. Before printing, check whether the laminate of the printing machine is flat and whether there are any foreign objects.

Adjusting heating time: If the temperature is insufficient during soldering, preventing the solder from melting, or if the temperature is too high, causing the solder to flow prematurely, this can result in solder residue on the pcb gold fingers. Adjusting the heating time by increasing or decreasing it can help control the soldering temperature and avoid this issue.

Enhancing cleaning: After soldering, the PCB should be cleaned promptly. During cleaning, care must be taken to protect the gold fingers, using appropriate cleaning solutions and methods to ensure that solder paste, debris, and other contaminants are completely removed.

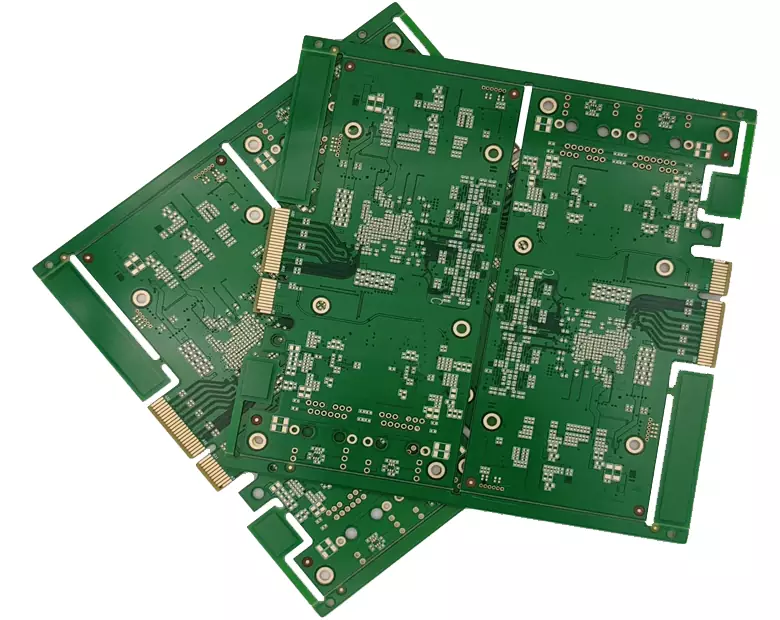

How to effectively prevent solder contamination on pcb gold fingers?

Process optimisation

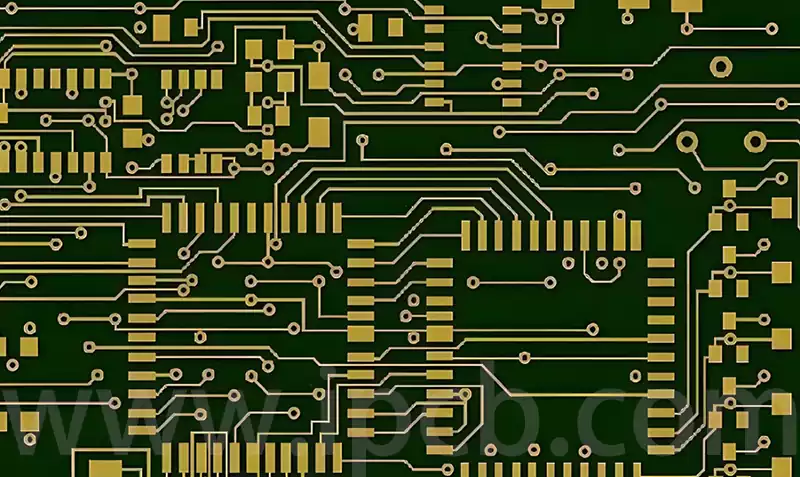

Printing stage: Carefully adjust the squeegee pressure, set the wiping frequency appropriately, and precisely control the distance between the printing board and the steel mesh to ensure uniform and adequate solder paste printing, preventing overflow.

Component placement stage: Set the appropriate placement pressure to ensure secure component placement while minimising the risk of solder powder being squeezed out, thereby reducing the likelihood of solder contamination.

Equipment Maintenance: Thoroughly clean and maintain the machine, regularly clean the equipment, reduce contamination levels, and create a clean and stable production environment for SMT placement.

Steel mesh adjustment: Based on actual production requirements, reasonably reduce the size of the steel mesh openings and strictly control the amount of solder paste applied to prevent excessive solder paste from adhering to the gold fingers.

Reflow soldering parameters: Use a curve with a slow temperature rise rate and a higher uniform heating temperature to ensure that the solder paste melts and flows evenly during reflow soldering, avoiding solder wetting caused by abnormal temperature changes.

Material Management and Solder Paste Selection

Ensuring the quality and consistency of solder paste is critical. Ensuring solder paste quality, selecting low-splash solder paste, managing moisture protection for components and PCBs, and designing appropriate gold plating layers for gold fingers are all important measures to prevent solder wetting on gold fingers.

Use high-quality solder paste and store it strictly according to specified methods to ensure its performance stability. Additionally, regularly inspect the solder paste usage and promptly replace expired or degraded solder paste, which is an indispensable step.

Solder Paste Selection: It is recommended to use low-splatter solder paste, which produces fewer splatters during printing and soldering, thereby reducing the risk of gold finger solder wetting.

Wetting rate: Select solder paste with a slower wetting rate, as this allows the solder paste to spread more evenly when in contact with the PCB board and components, reducing abnormal adhesion.

Moisture protection for components and PCBs: Ensure that the moisture content of components and PCBs is low, as moisture can affect the performance of solder paste and solder results. In a low-moisture environment, the likelihood of solder paste splatter is reduced, thereby minimising solder wetting on pcb gold fingers.

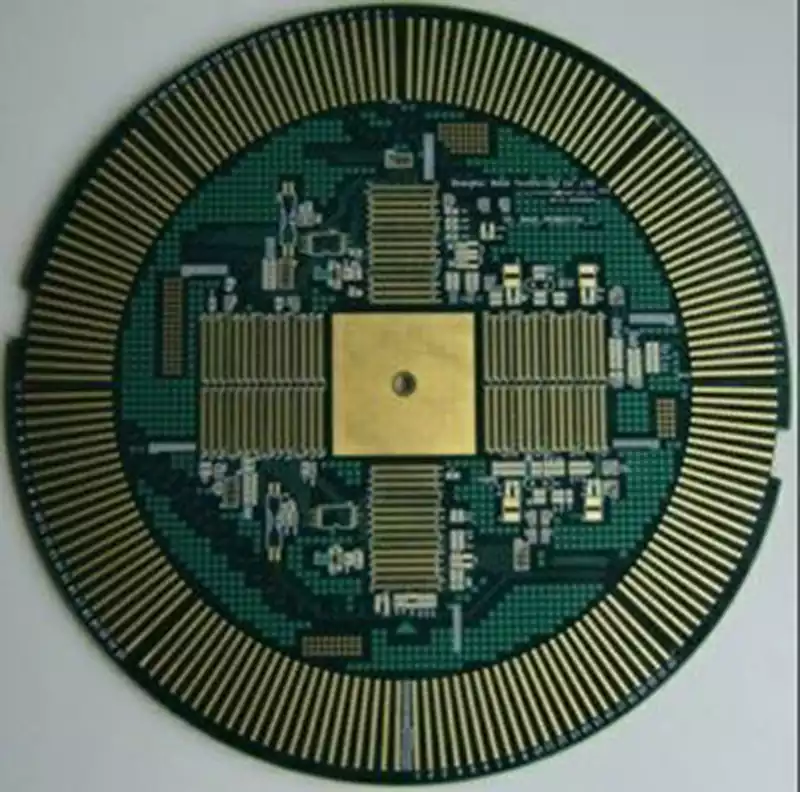

Gold plating layer for gold fingers: Design an appropriate gold plating layer for gold fingers, which not only enhances conductivity and oxidation resistance but also reduces the risk of nickel exposure, thereby avoiding abnormal reactions between nickel and solder paste that cause solder wetting issues.

Solder wetting on pcb gold fingers is a common challenge in electronics manufacturing, but it can be effectively avoided through process optimisation and material management. From source control to meticulous adjustment of production parameters, every step of continuous improvement contributes to ensuring the high quality and reliability of PCBA products.