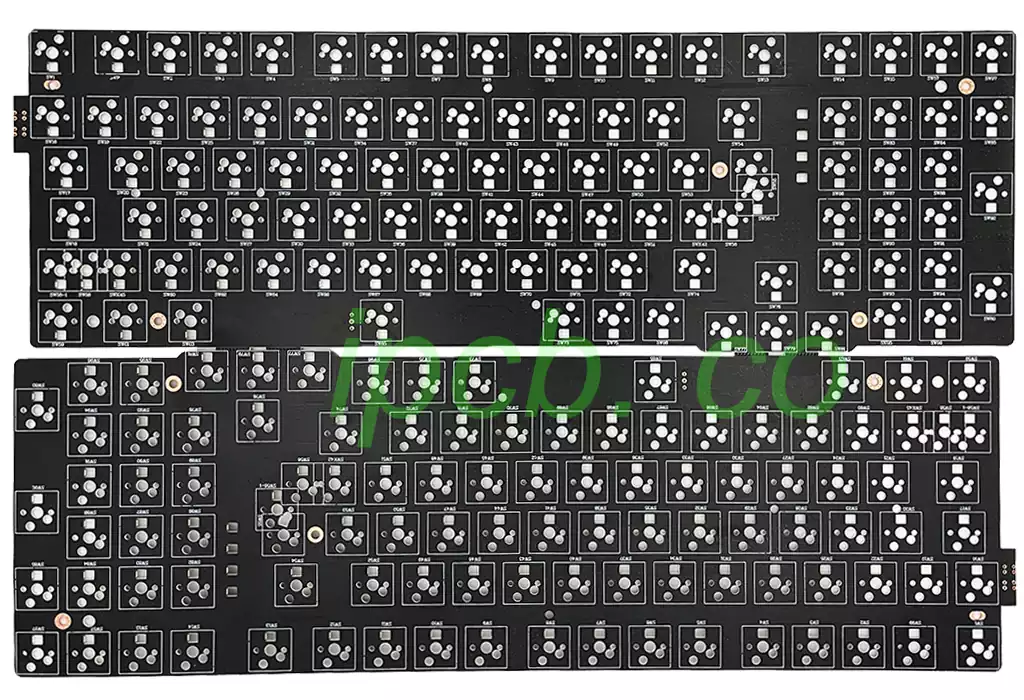

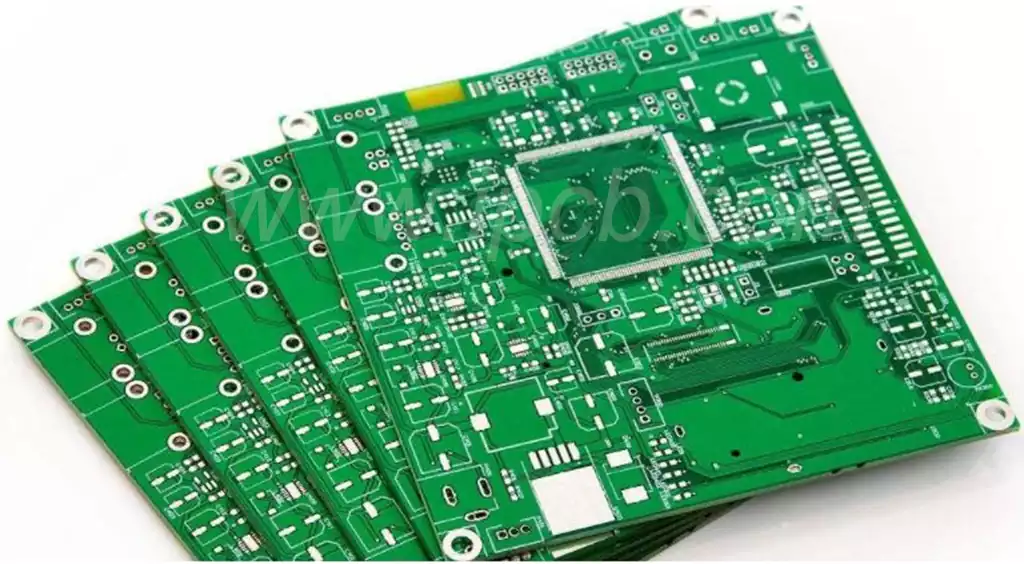

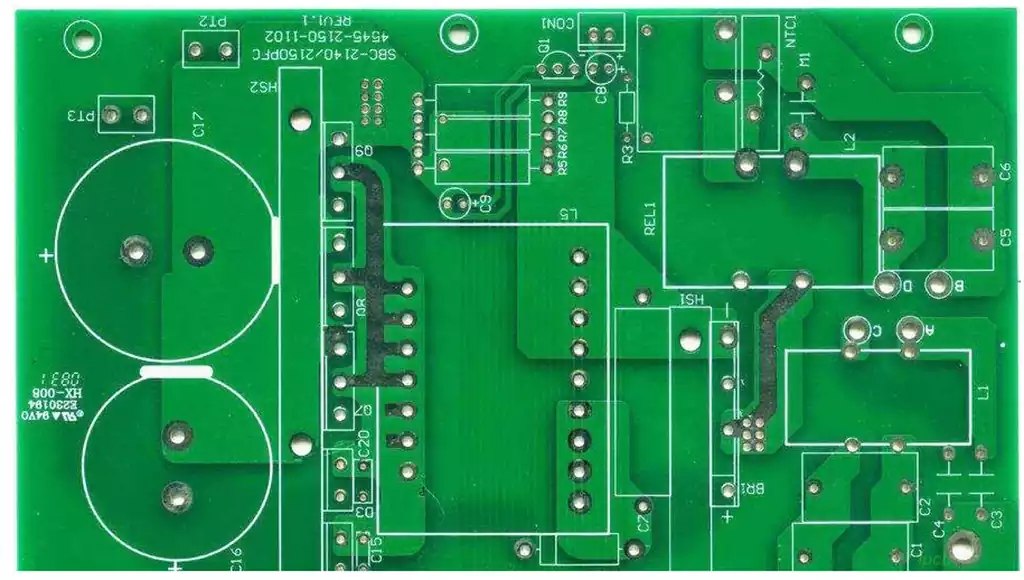

Surface mount PCB, that is, a variety of electronic components directly mounted on the surface of the PCB, and then fixed by welding and other processes. This technology eliminates the traditional plug-in technology of piercing, pin bending and other cumbersome steps, greatly simplifying the manufacturing process and improve production efficiency. At the same time, because the surface mounted components are smaller in size and lighter in weight, it also greatly improves the overall performance and reliability of electronic products.

Advantages of SMT (surface mount technology) assembly:

High assembly density: SMT uses leadless or short leaded surface mount components, which makes the size and weight of electronic products greatly reduced. Typically, the use of SMT technology can make the volume of electronic products reduced by 40% – 60%, weight reduction of 60% – 80%.

High Reliability: Because SMT components are firmly mounted and highly resistant to vibration, the defect rate of solder joints is extremely low. In addition, the characteristics of no lead or short lead also reduces the parasitic inductance and capacitance of the lead, improves the high-frequency and high-speed performance of the circuit as well as the thermal efficiency of the device, which further enhances the reliability of the product.

Good high-frequency characteristics: Because SMT has short component leads and small parasitic capacitance and parasitic inductance, it can reduce electromagnetic interference and radio frequency interference and improve the high-frequency characteristics of the circuit.

Easy to realize automation: SMT assembly process is highly automated, which can greatly improve production efficiency, while reducing production costs.

Reduce energy consumption and raw material consumption: SMT technology can reduce the consumption of raw materials and save energy, which is conducive to environmental protection and sustainable development.

In general, SMT assembly technology has been widely used in modern electronics manufacturing with its advantages of high assembly density, high reliability, good high-frequency characteristics, easy to automate and reduce energy and raw material consumption.

Disadvantages of SMT assembly:

While SMT assembly offers many advantages, there are several challenges to keep in mind:

Quality Control Challenges: Due to the high-speed, automated nature of the surface mount assembly process, problems in the assembly line can lead to a large number of defective assemblies before a problem is detected.

Repair or Replacement Difficulties: The small size of surface mount components and the high density of pcb boards make replacement or repair difficult. In addition, manual visual inspection is challenging and requires automated inspection equipment, which can increase overall production costs.

Reliance on solder joints: SMT relies more on solder joints for mechanical and electrical connections than through-hole technology. As a result, any defects in these joints can jeopardize the reliability of the component.

Difficulty in part identification: The small size of surface mount components often makes clear marking challenging, especially on passive components. This can lead to problems if devices are confused. They need to be positively identified or discarded.

Increased heat and moisture sensitivity: Surface mount packages experience higher temperatures during soldering than through-hole components, which can lead to thermal stress if the components are not adequately acclimated to these temperatures. In addition, some types of SMT pcb components are also susceptible to moisture absorption, which can lead to internal damage and a phenomenon known as “popcorn” when heated up quickly during the soldering process.

Strict cleanliness requirements: Surface mount components are placed very close to the surface of the substrate with less clearance than through-hole packages. This requires strict process controls to ensure cleanliness and prevent contamination that can disrupt assembly and performance.

The emergence and development of surface mount PCB technology has revolutionized modern electronics manufacturing. It not only improves productivity and quality, but also promotes the miniaturization, thinness and high performance of electronic products.