Thermal board,as a kind of thermal isolation material, its main function is to block the transfer of heat and ensure the effective isolation of heat energy. In the fields of construction, pipe insulation and air-conditioning pipe insulation, thermal insulation board plays a vital role in significantly reducing heat loss and thus improving the utilization of energy. In addition, this material in the reduction of noise, fire, water and antibacterial also has excellent performance.

Heat” in PCBs

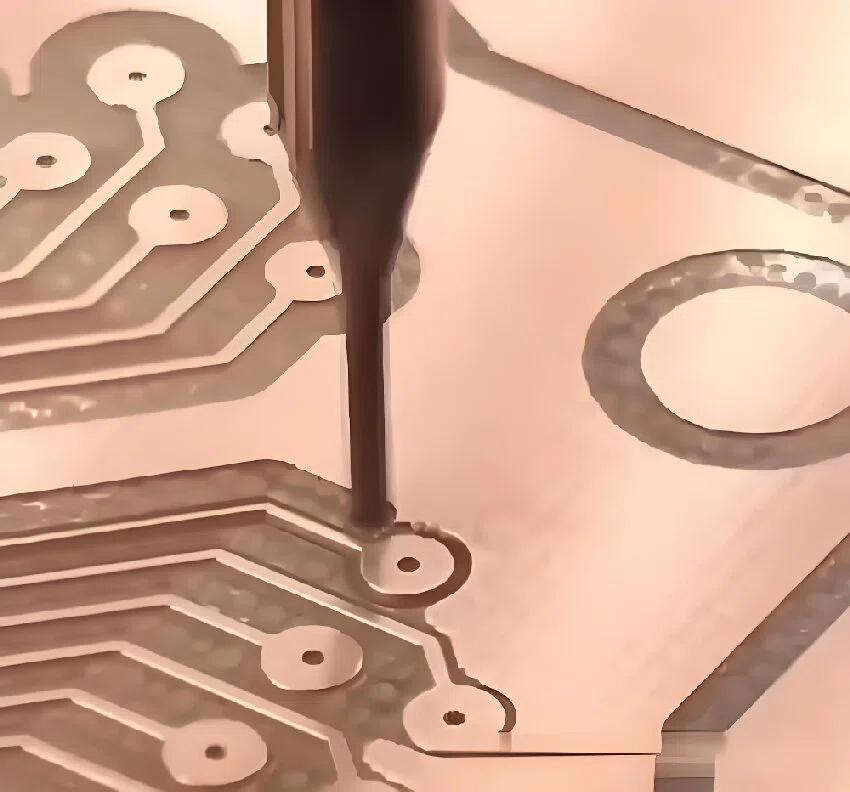

In PCB manufacturing terminology, “heat” usually refers to a special structure whereby pads are connected to flat surfaces by means of semicircular gaps designed to ensure good electrical contact while minimizing thermal contact. It is possible to imagine creating a circular spacing area around the copper pads on a circuit board to keep them at a certain distance from the flat surface.

Properties of Thermal board

1) Thermal insulation board material is an asbestos-free, high-temperature resistant laminate.

2) High-strength insulation panels possess high compression and flexural strength, making them ideal for applications requiring high strength.

3) High-temperature-resistant insulation boards have a low rate of expansion in high-temperature environments, are less likely to lose compressive strength, and maintain stable dimensions even under prolonged high-temperature conditions.

(4) according to different application requirements, insulation board provides standard and customized hole processing type for users to choose.

(5) The thermal insulation plate product series are diverse, to meet the needs of different high temperatures and thermal conductivity.

6)Each product can maintain stable dimensions and excellent insulation effect when heated under the specified use temperature.

Thermal board is a material specialized in heat isolation and is widely used in construction, aerospace and automotive manufacturing. Its main function is to lower the surface temperature of an object, thereby reducing heat transfer and energy loss. There is a wide range of materials used to manufacture heat insulation panels, each with its own unique characteristics and application scenarios.

1) Polystyrene Sheet

Polystyrene board is a foam material based on polystyrene. It possesses excellent insulating and flame retardant properties, making it a preferred material in the field of building insulation and thermal insulation. Advantages of polystyrene board include light weight, high strength, resistance to water, acid and alkali corrosion, and excellent insulation. However, its flammability needs to be improved by adding flame retardants.

2) Glass Wool Board

Glass wool board is an insulating material made of glass fibers. It has low density, light weight, high flexibility, good insulation properties, flame retardant and corrosion resistance. Glass wool boards are widely used for insulation needs in construction, aerospace and automotive manufacturing.

3) Polyurethane Board

Polyurethane boards are made from polyurethane as the base material by adding foaming agents and additives. It is characterized by light weight, high strength, excellent insulating properties, water resistance, acid and alkali corrosion resistance and flame retardancy. Polyurethane panels are mainly used for thermal insulation needs in areas such as building insulation, cold storage equipment and automobile manufacturing.

4) Aluminum silicate wool board

Aluminum silicate wool board is an insulation material made from aluminum silicate. Its features include low density, light weight, good insulating properties, flame retardancy and corrosion resistance. Aluminum silicate wool board plays an important role in high temperature equipment insulation, kiln insulation and building insulation.

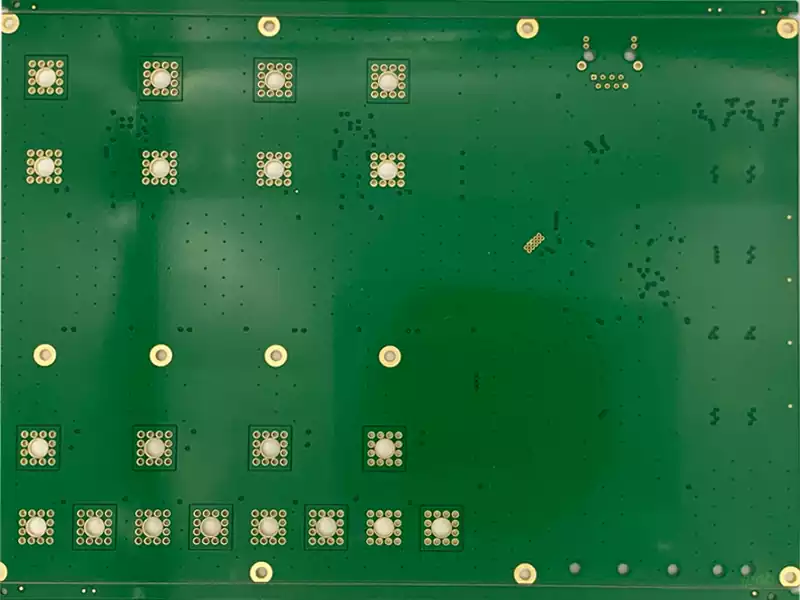

In PCB design, the application scenario of thermal Thermal board is very wide.

High-performance processor heat dissipation: For components with high heat generation, such as high-performance processors, heat-insulating boards can be placed underneath them to minimize the impact of heat on other components and improve heat dissipation efficiency at the same time.

Sensitive component protection: for temperature-sensitive components, such as high-precision sensors, etc., can be placed underneath the thermal insulation board to reduce the temperature around the component, to protect it from high temperature.

PCB local thermal isolation: In some cases, it is necessary to thermally isolate a certain area of the PCB from other areas. This can be placed in the region below the thermal insulation board, blocking the transfer of heat.

With the continuous development of electronic equipment and performance enhancement, the PCB design of thermal management requirements are increasingly high. As an effective thermal management material, the heat thermal board plays a key role in PCB design. Through the rational use of thermal insulation boards, the thermal efficiency of PCB boards can be significantly improved, sensitive components can be protected, and heat distribution can be optimized, providing a strong guarantee for the stable operation of electronic equipment.