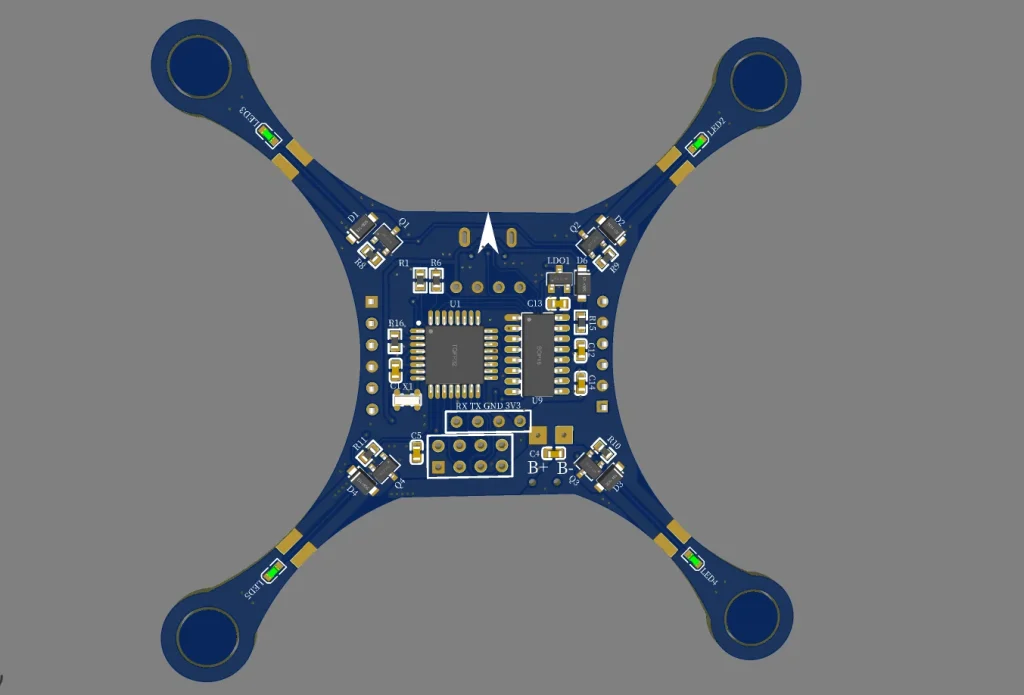

Small pcb boards refer to base plates that secure and interconnect electronic components through circuit design. Compared to traditional circuit boards, these compact boards are typically employed in scenarios with limited space requirements, such as smart devices and wearables. Components including resistors, capacitors, and chips are interconnected via conductive pathways to form a complete circuit system.

Small pcb boards refer to base plates that secure and interconnect electronic components through circuit design. Compared to traditional circuit boards, these compact boards are typically employed in scenarios with limited space requirements, such as smart devices and wearables. Components including resistors, capacitors, and chips are interconnected via conductive pathways to form a complete circuit system.

The applications of small pcb boards are extensive, primarily concentrated in the following domains:

Consumer Electronics

Smartphones, tablets, televisions, audio systems, and other consumer electronics rely heavily on small circuit boards. As technology advances, electronic devices become increasingly compact while offering greater functionality – a testament to the efficient design and high integration capabilities of small circuit boards.

Wearable Devices

Devices such as smartwatches, fitness trackers, and earphones require not only lightweight, comfortable designs but also robust processing capabilities and extended battery life. These demands rely heavily on the intricate design and high-density integration achievable with small pcb boards.

Automotive Electronics

In modern vehicles, an increasing number of electronic components are employed in control systems, safety equipment, and entertainment systems. Compact circuit boards enable these electronic systems to be densely integrated within the vehicle’s limited space, ensuring functional diversity and reliability.

Medical Devices

Whether in portable electrocardiogram (ECG) monitors or precision surgical equipment, compact circuit boards play a critical role. They facilitate device miniaturisation while enhancing accuracy and stability.

As demand for electronic devices continues to grow, the technology behind small pcb boards is advancing steadily. Future circuit boards will evolve in the following directions:

Higher Integration and Miniaturisation

With continuous improvements in chip technology, small pcb boards will achieve ever-greater integration while further reducing their physical size. This will enable electronic devices to become not only more powerful but also lighter and more comfortable to use.

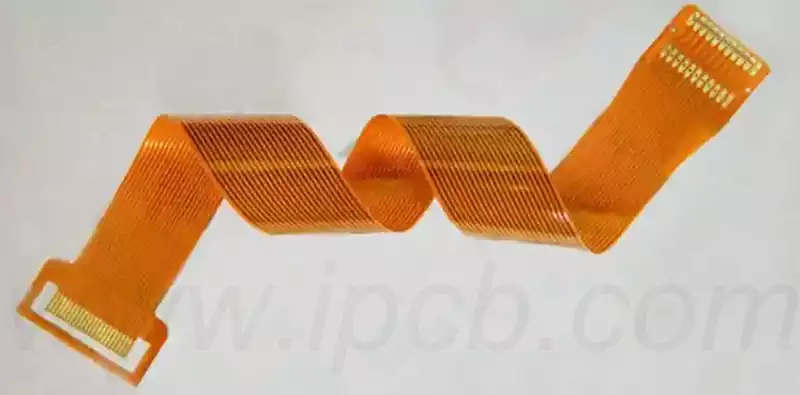

The Development of Flexible Circuit Boards

Flexible printed circuits (FPCs) are bendable circuit boards suitable for more complex or irregular shapes. With the proliferation of wearable devices and smart clothing, flexible circuit boards will become a major trend in future circuit board design.

Environmental Sustainability

As environmental standards rise, the materials and manufacturing processes for small pcb boards will increasingly prioritise sustainability. Lead-free soldering and the use of recyclable materials will become mainstream practices in the circuit board industry.

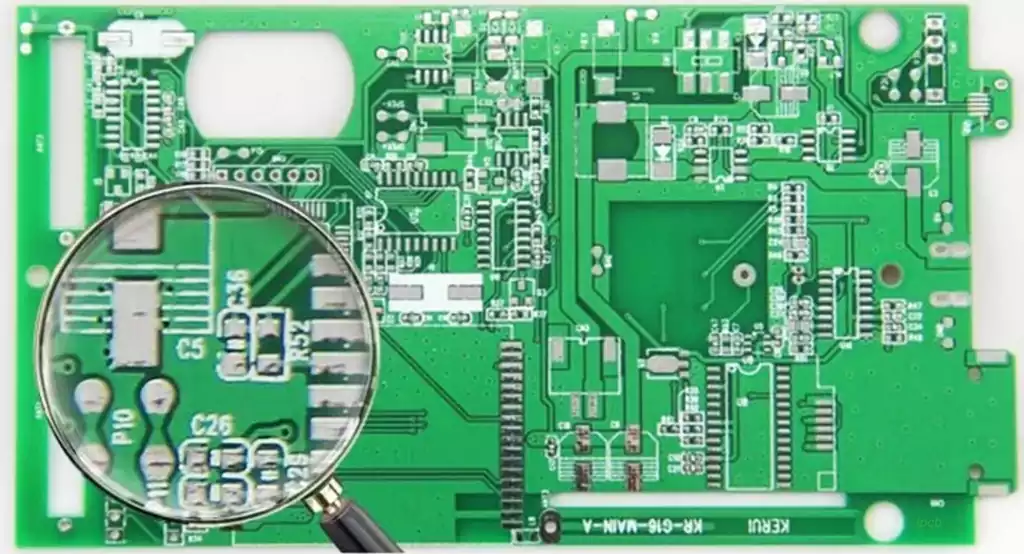

Despite their significant role in the electronics industry, the design and manufacture of small pcb boards continue to present numerous challenges.

Thermal Management Issues

Increased integration leads to higher power density in small pcb boards, generating greater heat. Excessive thermal energy can cause component damage, compromising board performance and lifespan. Effectively managing heat to prevent overheating represents a critical future challenge. Novel thermal management materials, design optimisation, and intelligent cooling systems will be key solutions to this problem.

Reliability and Interference Resistance

Small pcb boards may encounter diverse extreme environments across various applications, including strong electromagnetic interference, high temperatures, and humidity. Enhancing board reliability to ensure stable operation under harsh conditions is a critical consideration for manufacturers. Future circuit boards will require stronger interference resistance and environmental adaptability.

Manufacturing Costs and Material Constraints

Despite ongoing technological advancements in small pcb boards, high-performance boards still demand costly materials and complex manufacturing processes. As demand for compact circuit boards grows, balancing cost reduction with performance maintenance and adopting more environmentally sustainable materials will be pivotal to future industry development.

Intelligent and Adaptive Circuit Boards

Driven by advancements in artificial intelligence and machine learning, future small pcb boards may achieve self-regulating and adaptive capabilities. For instance, boards could automatically adjust power consumption based on real-time workload, optimise signal transmission paths, or even perform self-diagnosis and repair during malfunctions. Such intelligent circuit boards will propel the further evolution of electronic products.

Small pcb boards occupy a pivotal position in modern electronic technology. Through precision design and efficient integration, they propel the advancement and innovation of diverse smart devices. As technology continues to advance, small pcb boards will evolve towards higher integration, miniaturisation, and intelligence, while simultaneously confronting challenges such as thermal management and reliability.

Regarding environmental sustainability, future circuit boards will increasingly prioritise green manufacturing and material innovation. Whether in consumer electronics, medical devices, or smart vehicles, small pcb boards will persistently play a central role across multiple domains, propelling continuous technological innovation and progress.