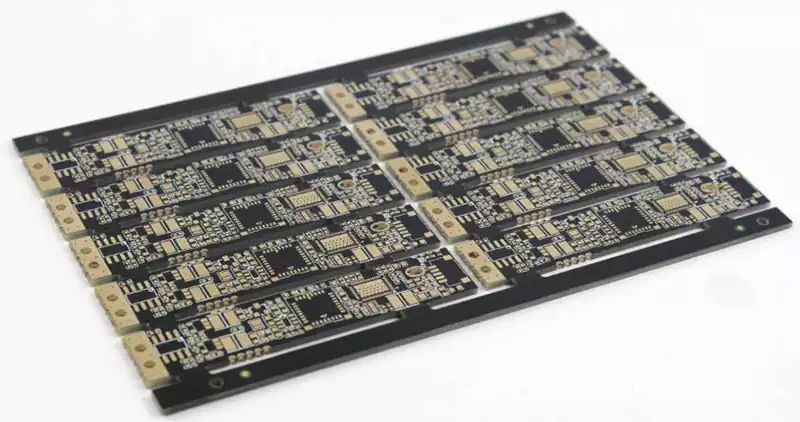

Smartphones predominantly utilise black PCB, not for electrical performance considerations, but as a strategic decision driven by aesthetic appeal, advanced manufacturing processes, and brand positioning. Given the highly compact internal structures of modern smartphones, the significance of PCB colour extends far beyond mere aesthetic enhancement. Whilst green PCBs remain predominant across broader electronics applications, smartphone manufacturers—particularly those producing mid-range and flagship models—remain steadfast in their adoption of black PCBs.

This preference for black PCB in smartphones stems from five key factors: aesthetic appeal, demonstration of manufacturing prowess, functional advantages, deterrence against reverse engineering, and brand positioning strategy.

Aesthetic Appeal and Perceived Quality

Black PCB provides a unified backdrop for the diverse components within smartphones, thereby reducing visual clutter. Components such as chips, resistors, and capacitors typically exhibit varied colours, including silver, green, and gold. The black background contributes to a cleaner, more cohesive, and technologically advanced appearance for the circuit board. This aesthetic advantage is crucial for brands seeking to convey premium quality when consumers or reviewers examine the device’s internals.

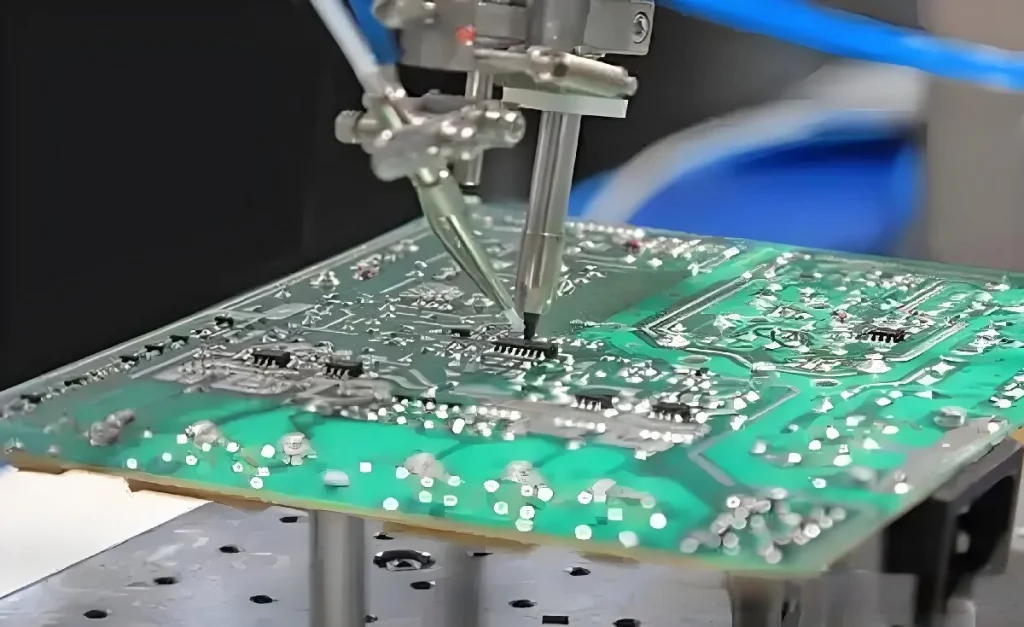

Demonstration of Manufacturing Capabilities

The production of black PCB presents significant technical challenges. During manufacturing, dark opaque pigments demand high-precision exposure and alignment. Even minute dust particles or deviations in exposure settings can cause visible defects,thereby reducing product yield.Consequently,the adoption of black PCB reflects a manufacturer’s advanced process capabilities and stringent quality control.

Functional Advantages: Light Absorption and Sensors

Black PCB helps minimise internal light reflection. Smartphones integrate multiple sensors, such as proximity sensors and cameras, where stray light can compromise sensor accuracy. Black surfaces absorb stray light, thereby enhancing sensor reliability. Furthermore, black theoretically offers a slight advantage in thermal radiation, complementing dedicated heat dissipation solutions like copper foil and heat sinks to aid thermal management. The black coating also shields circuits from environmental factors such as temperature and humidity, which can affect overall PCB performance. However, black PCB boards consist of a cobalt and carbon mixture, potentially resulting in relatively poorer conductivity.

Deterrence Against Reverse Engineering

While not entirely impenetrable, black PCB effectivelies increase the difficulty of reverse engineering. With surface traces almost entirely obscured, visual inspection or standard scanners struggle to discern circuitry, raising the barrier for competitors to acquire and replicate designs.Nevertheless, specialised reverse engineering teams can overcome this obstacle using advanced imaging techniques like X-ray tomography.For instance,non-destructive X-ray tomography combined with advanced 3D image processing and analysis can automate reverse engineering,significantly reducing time and cost.Furthermore, techniques like placing un-soldered components or dummy networks can increase reverse engineering difficulty at the system design level.Abrasion of markings on ICs or the use of encapsulation compounds also heightens the challenge.

Brand Differentiation and Market Positioning

Black PCB predominantlies feature in high-end devices, such as flagship models from Apple, Samsung, and Huawei, whereas green PCBs are more prevalent in entry-level products. This distinction reinforces brand perception, with black symbolising luxury and innovation, while green emphasises value for money.

While black PCB offers numerous advantages, they also present limitations:

- Debugging challenges: Dark backgrounds complicate circuit inspection, test point identification, and defect detection during R&D and maintenance. Lighter colours (e.g., green) provide superior contrast for silkscreen labels and circuit traces.

- Higher cost: Black PCB exhibits lower yield rates and demand more complex manufacturing processes, thereby increasing production expenses. Conversely, green solder mask inks are cost-effective and readily available, making them ideal for budget-sensitive applications.

- No inherent electrical advantage: Colour does not influence electrical performance. Signal integrity depends on materials, laminate structure, and layout design.

The adoption of black PCB in smartphones presents both advantages and disadvantages. While aligning with premium positioning through multiple benefits, manufacturers face challenges related to debugging and cost. A comprehensive assessment is required to make informed decisions based on individual circumstances, thereby enhancing product competitiveness.