Epoxy resin is a polymer material that is widely used in circuit board manufacturing and serves several important functions.It not only provides mechanical support and connections for electronic components, but also protects the circuit board from environmental factors.Due to its excellent insulating and thermal conductivity properties, epoxy resin has become an integral part of modern electronic devices.

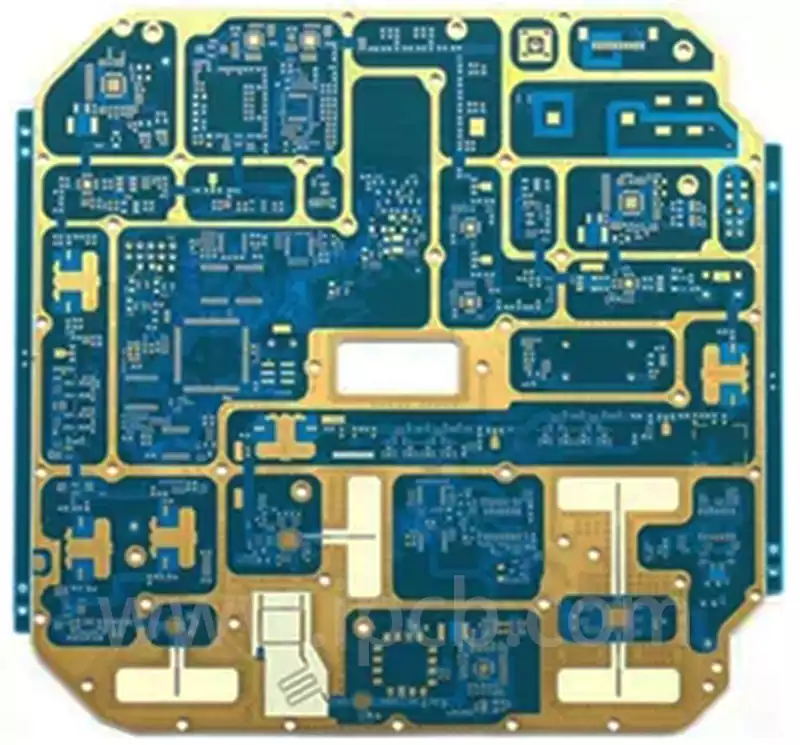

In the design of circuit boards (PCBs), they are used as a substrate to provide mechanical support and connection of electronic components. Its structure allows electrical connections to be made through wires and pads and other components, and its function enables various pcb components to be efficiently positioned and fixed on the circuit board, which lays the foundation for the reliable operation of the circuit.

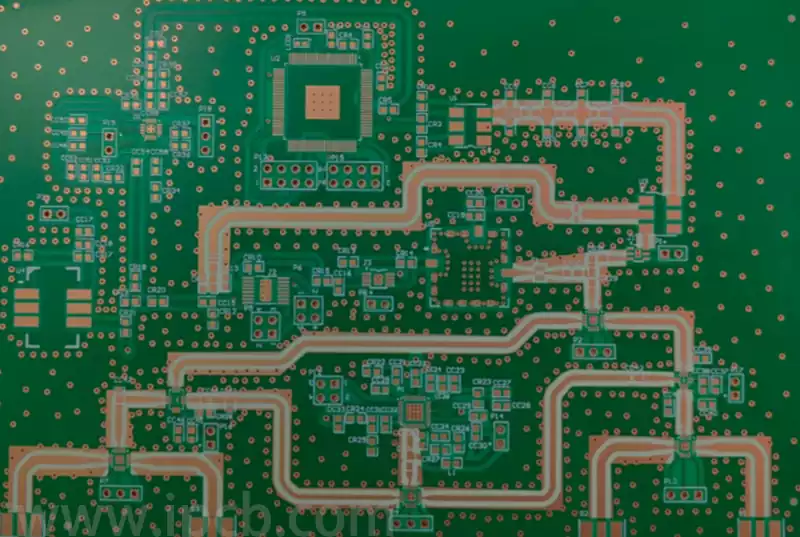

Wires and other electronic components on circuit boards often require good electrical insulation to prevent leakage or short circuits. They have excellent electrical insulation properties and can effectively block electrical currents,ensuring the safe and stable operation of circuit boards.

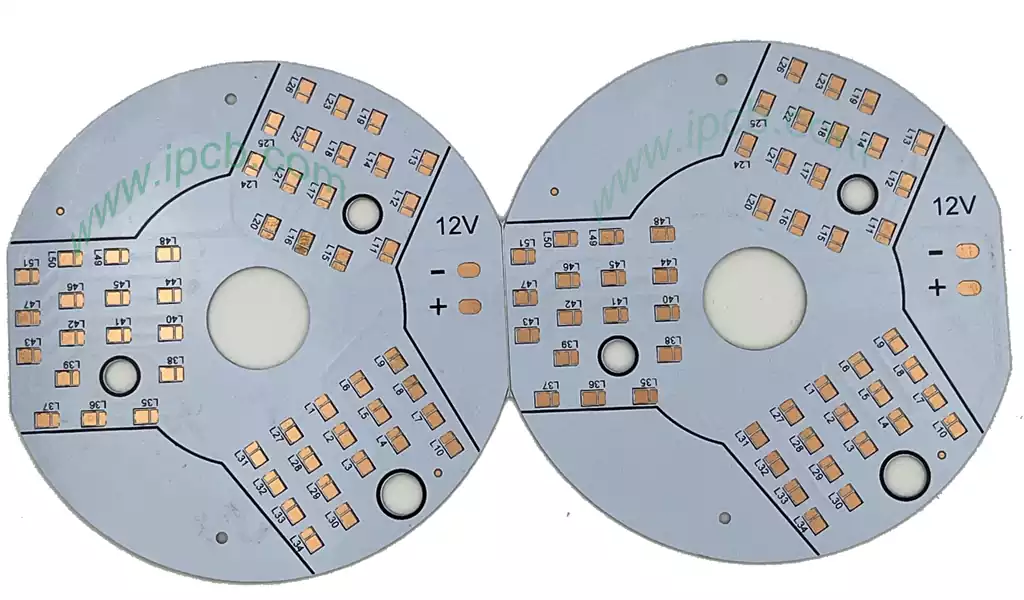

In addition to electrical insulation, it can also help dissipate heat.Modern electronic equipment generates a large amount of heat during operation, and the thermal conductivity of it helps to conduct heat away from the heating element, lowering the temperature of the power device and improving the efficiency and stability of the circuit board. While epoxy resins may not have the same thermal conductivity as some metallic materials, their combination of effects makes them still an effective heat dissipation solution.

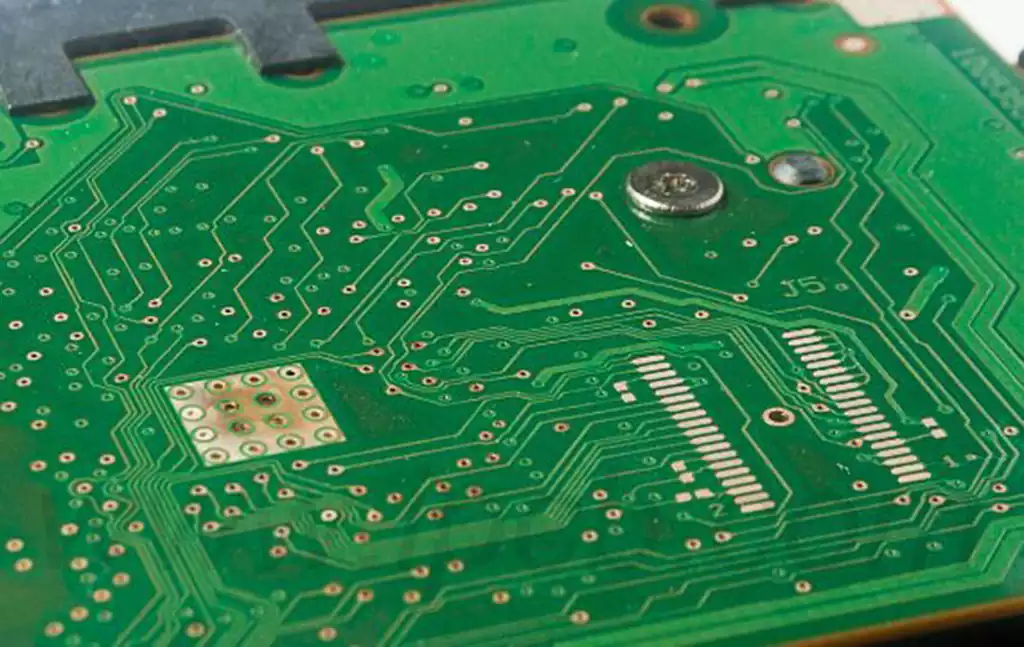

Epoxies also play an important role in protecting circuit boards. By encapsulating the board in epoxy, moisture, dust and other contaminants are effectively blocked. These environmental factors can lead to corrosion and short circuits, which can reduce the performance and life of electronic devices. Therefore, the use of it for encapsulation not only ensures the reliability of the circuit board, but also extends the life of the equipment.

How to choose the right material for circuit board applications

The first step in selecting the type of epoxy resin is to define the application requirements. Different applications require different properties, e.g. high-frequency applications usually require high electrical insulation and thermal stability. Glass fiber reinforced epoxy resins (e.g. FR4) are often ideal in such cases because of their excellent insulating properties to accommodate complex circuit design requirements.

The properties has a direct impact on the overall performance of the board.The main properties to focus on include insulation,heat resistance,chemical stability, and mechanical strength. For example, they have good chemical resistance and high temperature stability,making them ideal for use in industrial environments to prevent erosion and damage from the external environment.

The working environment that the circuit board will face is also an important consideration in selecting the type. For example,circuit boards operating in humid or high-temperature conditions need to have better resistance to moisture, heat and chemicals. Therefore, the selection of epoxy resins with good thermal stability and chemical resistance is necessary in such cases

Cost and productivity are equally important when selecting epoxy resins. Differences in price and processing methods between different types of epoxy resins may affect overall production costs. High-performance epoxy resins may result in a higher investment in the short term, but are still worth considering if they offer durability and reliability that reduces long-term maintenance costs.

In addition, technical parameters of epoxy resins, such as viscosity and curing time, should also be taken into consideration. For example, the viscosity of an epoxy resin will affect the ease of its coating and molding process, and higher viscosity resins may require stronger application techniques. In practical applications, epoxy resins with appropriate parameters should be selected according to specific technical requirements in order to improve production efficiency and product quality.

Epoxy resin plays a vital role in circuit board manufacturing. It not only provides the necessary mechanical support and electrical connections, but also effectively protects electronic components from environmental influences and improves the overall performance and reliability of the circuit board. When selecting the right epoxy resin, application requirements, performance characteristics, working environment and cost factors need to be considered comprehensively. Through the rational selection and use of epoxy resins, the durability and stability of electronic equipment can be significantly improved for the sustainable development of the modern electronics industry.