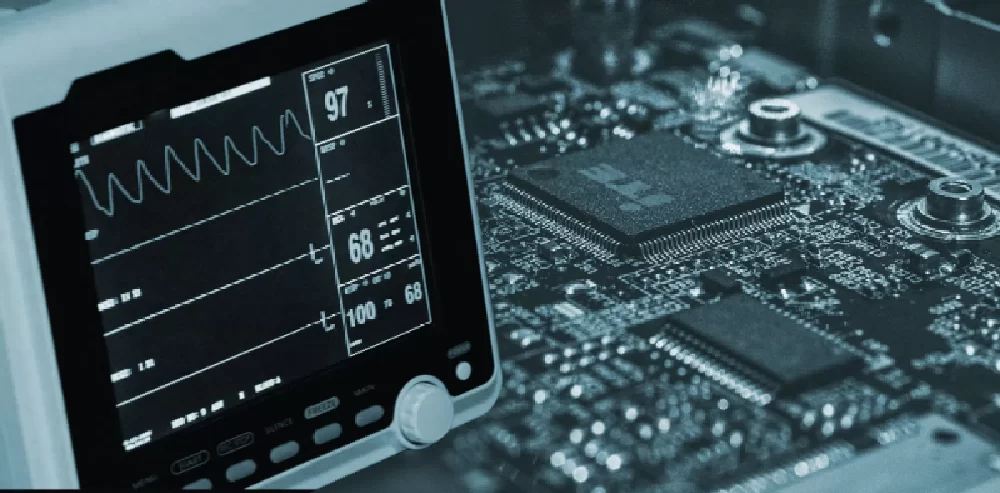

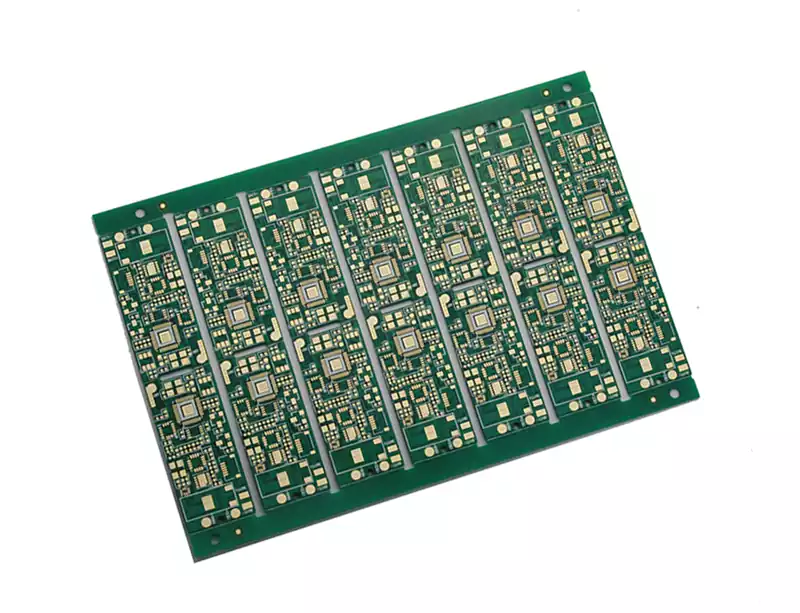

4-layer PCBs find extensive application across numerous sectors including consumer electronics, industrial control systems, and automotive electronics. Their pivotal role owes much to the core materials—the core board and prepreg. These two components work in tandem to form the stable physical framework of the 4-layer PCB.

4-layer PCBs and Core Materials

1.Core Value and Structure of 4-layer PCBs

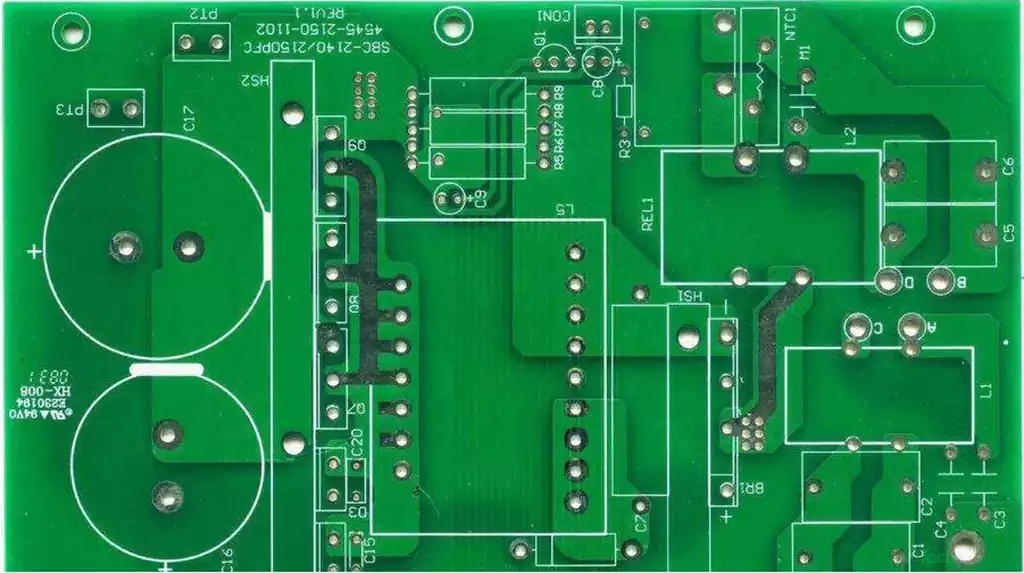

The 4-layer PCB represents an optimal solution in the electronics manufacturing industry, balancing cost-effectiveness with performance. Compared to double-layer boards, it achieves signal integrity improvements by adding two inner layers for routing, enabling the separation of signal layers from power/ground planes and significantly reducing electromagnetic interference. When contrasted with six-layer or higher multilayer boards, its production process is more mature and offers a distinct cost advantage, leading to its widespread adoption in consumer electronics, industrial control systems, automotive electronics, and other sectors. Their standard structure typically comprises a top signal layer, inner power/ground layers, and a bottom signal layer. The physical framework is entirely formed through the lamination of the core board with prepreg sheets.

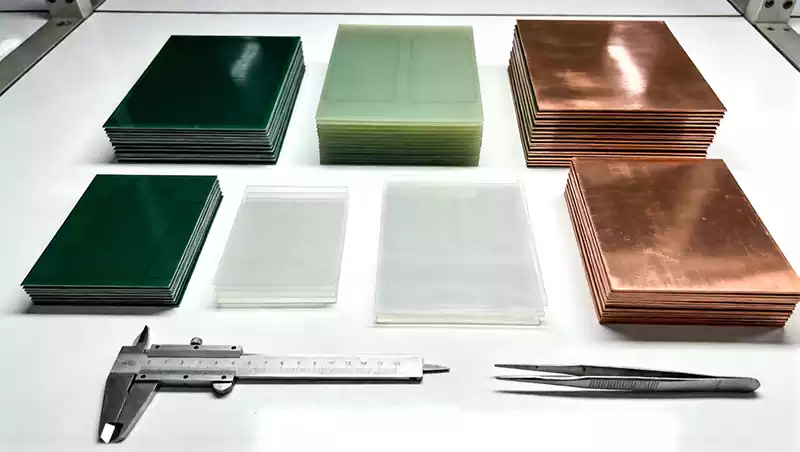

2.Core Board

The core board is a fully cured rigid substrate formed by impregnating glass fibre cloth with epoxy resin (commonly the FR-4 system) and curing it under high temperature and pressure. Both sides are clad with copper foil of a fixed thickness. It is not merely an ‘intermediate layer’ but the primary source of mechanical strength for 4-layer PCBs – akin to load-bearing walls in construction, determining the board’s overall rigidity, resistance to bending, and fundamental thickness. Core board thicknesses range extensively from 0.1mm to 1.2mm (excluding copper foil thickness), with common specifications concentrated between 0.3mm and 0.5mm. Selection can be tailored flexibly to meet the target total thickness and rigidity requirements of the 4-layer PCB.

3.Prepreg

Prepreg exists in a semi-cured state (B-stage curing). It similarly employs glass fibre cloth as a carrier, impregnated with epoxy resin and partially dried, without copper foil coverage. It remains solid at ambient temperatures but melts and flows under heat and pressure, filling interlayer voids and fully curing (Stage C curing). This achieves tight bonding between the core board and copper foil, as well as between core boards, while forming an interlayer insulating medium. Semi-cured sheets are categorised by glass cloth specifications, with 1080, 2116, and 7628 being common types. Their post-lamination thicknesses correspond to 0.065–0.075 mm, 0.105–0.125 mm, and 0.180–0.200 mm respectively, adjustable through single or multiple layers.

Core Board and Prepreg Functional

1.Core Board

The primary function of the core board is to provide structural support, determining the 4-layer PCB’s bending strength and dimensional stability. In automotive bumpy environments and industrial equipment vibration scenarios, the core board effectively prevents circuit board deformation and cracking, ensuring component soldering reliability. Secondly, the double-sided copper foil of the core board serves as the carrier for the inner power/ground planes. Its copper thickness (commonly 1oz, equivalent to 35μm) directly impacts power carrying capacity and ground shielding effectiveness. Moreover, the core board’s thickness fundamentally determines the base thickness of the 4-layer PCB. When combined with laminate adjustments, standard total thicknesses such as 0.8mm or 1.6mm can be achieved (1.6mm being the most commonly used specification, offering optimal balance between cost and process compatibility).

It is noteworthy that the curing state of the core board determines its non-deformable properties. Once specifications are selected, the core rigidity and inner layer spacing of the 4-layer PCB are essentially fixed. Therefore, precise selection must be made during the initial design phase in conjunction with the mechanical requirements of the end product.

2.Prepreg

Prepreg serves as the core medium for interlayer bonding in 4-layer PCBs. Without its adhesive action, the core board and copper foil cannot form an integrated structure, leading to delamination and separation issues. During lamination, the resin flow properties of prepreg fill uneven areas in copper traces, ensuring tight interlayer bonding and enhancing structural stability. Simultaneously, the cured prepreg functions as an insulating dielectric layer, guaranteeing electrical isolation between signal and power planes. Its dielectric constant (Dk) directly influences signal transmission loss—high-frequency applications necessitate prepregs with low Dk values (e.g., 3.8) to minimise signal attenuation.

Compared to the fixed thickness of the core board, prepregs offer greater flexibility: by combining different types and quantities of prepregs, the interlayer dielectric thickness can be precisely adjusted to meet impedance control requirements (e.g., 50Ω single-ended impedance on the surface layer, 100Ω differential impedance). For instance, to achieve high-speed signal transmission, increasing the prepreg thickness can widen the gap between the signal layer and ground plane, thereby reducing interference.

Comparison of Advantages and Disadvantages

Core Board Characteristics

Advantages: Exceptional mechanical strength provides stable rigidity for 4-layer PCBs, offering superior resistance to bending and vibration; stable performance post-curing remains unaffected by subsequent processes, ensuring long-term dimensional stability; double-sided copper cladding allows direct use as an inner layer routing substrate, streamlining production. Additionally, core boards exhibit good thermal stability, maintaining structural integrity in high-temperature environments (e.g., industrial control equipment) and reducing deformation risks.

Disadvantages: Fixed thickness specifications offer limited flexibility, preventing independent adjustment of layer spacing via the core board alone; non-standard thickness core boards entail extended procurement cycles and higher costs, increasing production expenses and lead times for 4-layer PCBs; Excessively thick core boards increase the overall weight of 4-layer PCBs, rendering them unsuitable for ultra-thin devices (e.g., smartphones, portable medical equipment). Furthermore, the dielectric constant of core boards offers limited adjustment range, making it challenging to meet specialised insulation requirements in high-frequency applications.

Advantages and Disadvantages of Prepreg

Advantages: Flexible thickness adjustment achievable through multiple layers or model combinations to meet diverse dielectric thickness requirements, accommodating impedance control and insulation demands; Excellent flow properties enable thorough void filling during lamination, enhancing interlayer bonding strength and reducing delamination risks; Wide selection range of dielectric constants allows choice between standard (Dk=4.4) or low-loss variants based on signal frequency requirements, suitable for high-frequency and high-speed applications. Furthermore, prepregs are lightweight, minimising impact on overall 4-layer PCB thickness and weight, making them ideal for ultra-thin designs.

Disadvantages: Limited mechanical strength; cannot form a supporting structure independently and must rely on the core board to construct the 4-layer PCB framework; Performance is highly susceptible to lamination process variations; improper temperature or pressure control may cause insufficient resin flow, trapped voids, and other issues, compromising insulation properties and structural integrity; Thicker prepregs (multiple layers stacked) increase lamination complexity and may induce PCB warpage, necessitating strict adherence to symmetrical structural design principles.

The physical framework of a 4-layer PCB is not the sole contribution of either the core board or prepreg, but rather an integrated structure formed through their coordinated interaction according to specific logic. This synergy manifests across two key dimensions: the lamination process and structural design.

Synergy in Laminating Process

The laminating structure of a standard 4-layer PCB adheres to the ‘principle of symmetry’. Taking the most common total thickness of 1.6mm as an example, the typical stack-up is: Top copper foil (1oz) – Prepreg (2116 + 1080 combination, approx. 0.19mm) – Core board (0.4mm, double-sided 1oz copper foil) – Prepreg (symmetrical to top layer, approx. 0.19mm) – Bottom copper foil (1oz). During lamination, the prepreg melts under high temperature and pressure, bonding the top copper foil, core board, and bottom copper foil into a unified structure. The core board provides rigid support, while the prepreg ensures interlayer insulation and bonding strength, ultimately forming a stable physical framework.

Different application scenarios require adjusted collaboration methods: – High-frequency RF scenarios employ a ‘thin core board + thick prepreg’ solution (core board 0.4mm + prepreg 0.2mm/side), where thick prepreg enhances signal shielding and reduces interference; For automotive electronics and other applications demanding high rigidity, a ‘double-layer core laminate stack’ configuration (two 0.3mm core laminates combined with prepreg) can be employed. This increases bending strength from 150MPa to 250MPa, enhancing vibration resistance.

Performance Balancing in Structural Design

The interaction between the core laminate and prepreg directly determines the three key physical properties of 4-layer PCBs: mechanical strength, thickness precision, and insulation reliability. Mechanical strength is primarily governed by the core laminate, with the prepreg supplementing interlayer bonding strength to prevent delamination. Thickness precision is achieved through the core laminate’s base thickness combined with the prepreg’s fine-tuning, ensuring compliance with end-device installation requirements. Insulation reliability relies on the prepreg’s dielectric properties and lamination quality, while the core laminate’s curing stability reduces the risk of deformation in the insulating layer under stress.

Furthermore, the synergistic pairing of these components must also balance manufacturability and cost. For instance, selecting standard-thickness core boards (0.3mm–0.5mm) with conventional prepreg types (1080, 2116) enhances production yield (achieving over 98%) while reducing costs. Non-standard combinations not only increase process complexity but may also cause warping, voiding, and other defects that compromise product yield.

Practical Guide to Optimising the Physical Framework of 4-Layer PCBs

1.Key Considerations for Core Board Selection

Core board selection must prioritise alignment with the target overall thickness and mechanical requirements of the 4-layer PCB:

Standard 0.4mm-0.5mm FR-4 core boards are suitable for general consumer electronics (e.g., routers), balancing rigidity and cost; Ultra-thin devices employ 0.1mm–0.2mm thin core boards, with thicker prepregs used to adjust overall thickness; automotive electronics and industrial control equipment utilise 0.6mm–0.8mm thick core boards to enhance vibration resistance. Concurrently, core board copper foil thickness must align with power delivery requirements; inner layer power planes may utilise 2oz copper foil to bolster current-carrying capacity.

2.Prepreg Selection Principles

SMC selection must prioritise impedance control and insulation requirements: – For high-speed signal applications (e.g., DDR4, PCIe 4.0), employ low-Dk SMCs with precise thickness combinations (e.g., two 2116 sheets achieving 0.22mm dielectric layer) to ensure impedance deviation ≤±3%. – For standard applications, use conventional FR-4 SMCs, meeting thickness requirements through single or double-layer stacking. During lamination, maintain symmetry between upper and lower prepreg layers to prevent PCB warpage, controlling warpage within 0.5mm (standard requirement).

3.Core Process Control Points

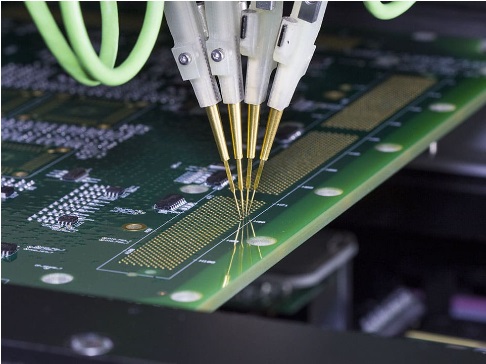

The lamination process is critical for ensuring synergistic performance:

During the heating phase, raise temperature from 50°C to 120°C at 2°C/min to allow gradual prepreg melting; During the pressing stage, apply pressure to 25 kg/cm² at 120°C and maintain for 30 minutes to ensure full resin flow; in the curing stage, raise temperature to 180°C and hold for 60 minutes to achieve complete prepreg curing. Concurrently, strictly control the storage environment for core boards and prepregs (humidity ≤60%, temperature 20°C–25°C) to prevent moisture ingress affecting lamination quality.

Both the core board and prepreg are indispensable for 4-layer PCBs. By precisely selecting the core board and prepreg and rigorously controlling the lamination process, the physical framework of the 4-layer PCB can be optimised. This achieves ideal mechanical strength, thickness precision, and insulation reliability, thereby meeting the diverse requirements of various electronic products and providing a robust foundation for their stable operation.