Ultra-high thermal conductivity aluminium substrate is a novel circuit board that achieves exceptional thermal performance by replacing the resin insulating layer within existing metal aluminium-based circuit board structures with a multi-film layer nanostructure diamond-like carbon (DLC) insulating layer.

Ultra-hyperconductive aluminium substrate is a utility model applicable to the printed circuit board field, providing an efficient heat dissipation aluminium substrate. It comprises an insulating layer, a circuit layer, a corrugated metal base layer, and a fixing base. The fixing base is positioned on one side of the corrugated metal base layer, while the opposite side of the corrugated metal base layer sequentially features the insulating layer and circuit layer. The fixing base consists of a plastic base equipped with internal threads for securing purposes. The incorporation of the corrugated metal substrate further enhances the aluminium substrate’s heat dissipation capabilities.

The thermal conductivity coefficient of high-conductivity aluminium substrate serves as a key metric for evaluating their heat dissipation performance, typically measured in W/mK (watts per metre per kelvin). The thermal conductivity of high-conductivity aluminium substrates significantly exceeds that of standard aluminium substrates,typically reaching 2.0 W/mK or higher. In practice, certain high-performance variants achieve thermal conductivities of 140–200 W/mK—two to three times that of copper plates and substantially surpassing conventional FR-4 fibreglass boards and standard aluminium substrates.

The thermal conductivity value primarily depends on the material and thickness of the metal layer.With identical metal layer material, thermal performance improves as the metal layer thickness increases. For instance, a high-conductivity aluminium substrate with an 18μm copper layer exhibits a thermal conductivity of 140 W/mK; whereas a 35μm copper layer can elevate this value to over 180 W/mK.

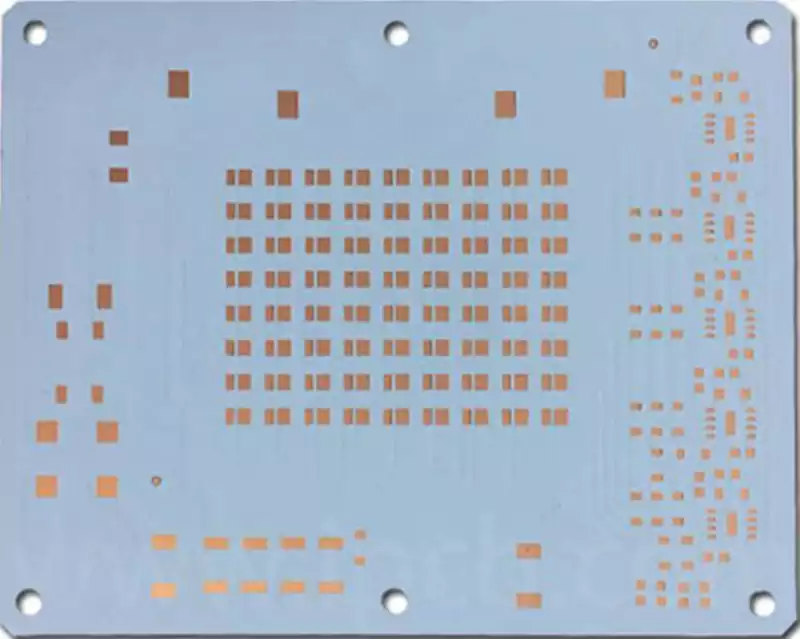

Structure of High-Conductivity Aluminium Substrate:

Circuit Layer (Copper Foil)

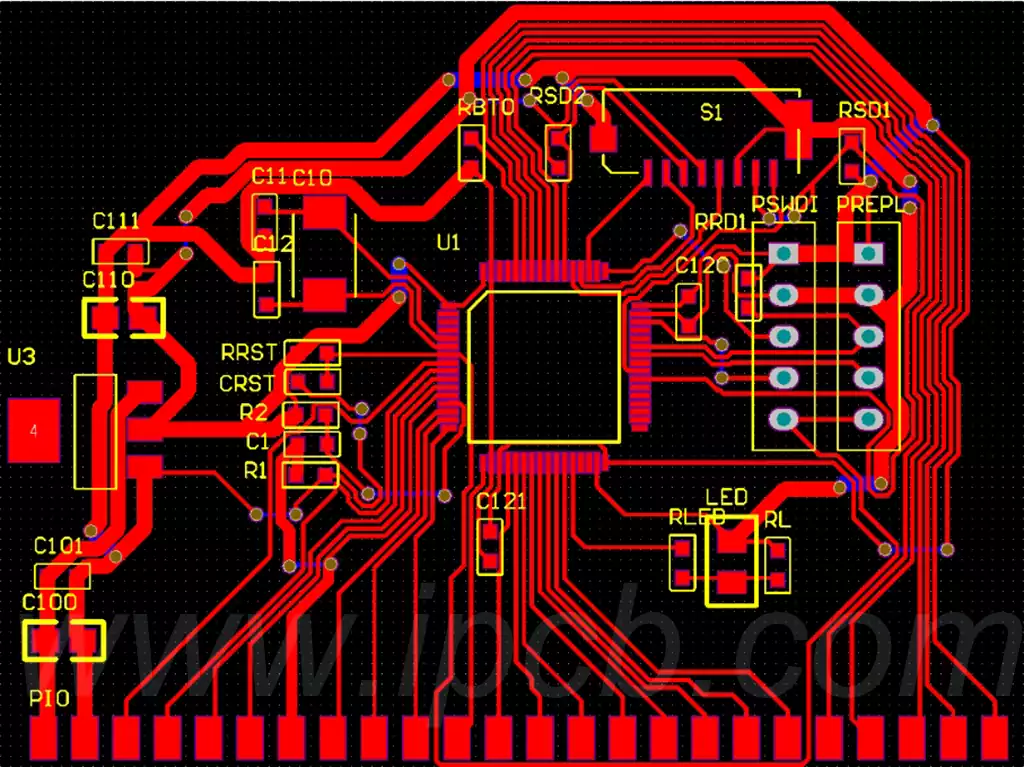

Function: Serves as the conductive layer, supporting electronic components and enabling electrical interconnections, equivalent to the copper clad laminate in conventional PCBs.

Material and Thickness: Typically employs electrolytic copper foil, with circuit patterns formed via etching processes. Common thicknesses range from 1oz (approximately 35μm) to 10oz (approximately 280μm) to accommodate varying current-carrying capacities and thermal dissipation requirements.

Characteristics: Copper foil thickness directly determines current-carrying capacity; greater thickness permits higher current loads. Additionally, its thermal expansion coefficient closely matches semiconductor chips, reducing the risk of solder joint cracking due to thermal stress during thermal cycling.

Insulating Layer (Thermally Conductive Insulation)

Function:

Electrical Insulation: Provides a robust, reliable barrier between circuit layers and the metal substrate to prevent short circuits.

High-Efficiency Thermal Conductivity: Serves as the primary thermal conduction pathway, efficiently transferring heat generated by circuit layers to the metal substrate.

Mechanical Bonding: Securely bonds circuit layers to the metal substrate, ensuring structural integrity.

Materials and Thickness: Typically composed of a high-performance polymer matrix (e.g., modified epoxy resin, polyimide) filled with highly thermally conductive specialised ceramic powders (e.g., aluminium oxide, boron nitride, aluminium nitride). Thickness is generally controlled between 50–200μm to ensure high thermal conductivity while maintaining electrical isolation.

Characteristics:

Low thermal resistance: A direct indicator of the ease with which heat traverses the layer, requiring minimal values.

High thermal conductivity: The material’s inherent heat transfer capability (unit: W/(m·K)) directly determines the aluminium substrate’s overall heat dissipation efficiency. Higher thermal conductivity facilitates faster, more efficient heat transfer from components to the heat sink substrate.

High dielectric strength: Must withstand high electric fields without breakdown to guarantee electrical safety.

Superior viscoelastic properties: Effectively buffers thermomechanical stresses arising from differing thermal expansion coefficients between circuit layers and the metal substrate, preventing delamination and cracking.

Long-term thermal stability/heat ageing resistance: Maintains stable performance without degradation under prolonged high-temperature operation in equipment.

Metal Substrate (Aluminium or Copper Plate)

Function: Serves as the mechanical support core and primary heat dissipation pathway for the aluminium substrate, efficiently diffusing and ultimately dissipating heat conducted from the insulating layer.

Material and Thickness: Common materials include aluminium sheets (e.g., alloys 1060, 5052, 6061), though copper sheets may be used (offering superior thermal conductivity but at higher cost). Thickness ranges from 0.8mm to several millimetres, depending on application requirements.

Characteristics:

High thermal conductivity: Aluminium exhibits a thermal conductivity coefficient of approximately 200–220 W/(m·K), enabling rapid heat transfer from the insulating layer to the heat dissipation surface.

Excellent mechanical properties: Including strength (resistance to bending and deformation) and hardness (influencing machinability and wear resistance), capable of withstanding machining processes and thermal stresses.

Lightweight: Aluminium’s density is significantly lower than copper (Al ≈ 2.7 g/cm³, Cu ≈ 8.9 g/cm³), offering distinct advantages in applications requiring both heat dissipation and weight reduction.

Surface Treatment: Processes such as anodising enhance corrosion resistance, insulation properties, or improve adhesion.

Special Structures (Double-sided or Multi-layer Aluminium Substrates)

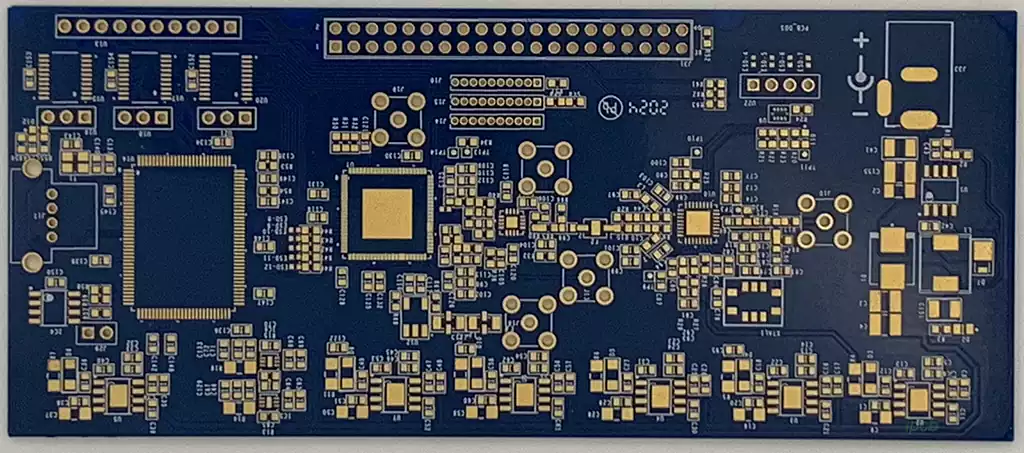

Double-sided aluminium substrate: Features a more complex symmetrical five-layer laminate structure (circuit layer-insulating layer-metal base layer-insulating layer-circuit layer), enabling double-sided routing. Suitable for higher-density, more intricate circuit designs.

Multi-layer aluminium substrate: Rarely employed in multi-layer boards, these can be fabricated by laminating standard multi-layer boards with insulating layers and aluminium bases to meet complex circuitry and thermal management requirements.

Characteristics of High-Conductivity Aluminium Substrate:

Excellent Thermal Expansion Matching

Aluminium’s thermal expansion coefficient (approximately 23 ppm/°C) closely aligns with that of semiconductor chips (e.g., silicon, with a coefficient of approximately 4 ppm/°C). This minimises the risk of solder joint cracking due to thermal stress during thermal cycling, thereby enhancing product reliability.

Mechanical strength and stability

Aluminium substrates possess high mechanical strength, exhibiting superior bending resistance and vibration damping compared to standard PCBs. This makes them suitable for harsh environments such as automotive electronics and industrial equipment. Additionally, they can operate continuously at temperatures exceeding 150°C, demonstrating excellent high-temperature resistance.

Electrical Insulation

The insulating layer employs a polymer material filled with specialised ceramics, typically achieving a dielectric strength ≥3 kV/mm. This satisfies the requirements of most high-voltage applications, ensuring electrical isolation between circuits and the metallic substrate.

Lightweight and Cost Advantages

Aluminium’s low density (2.7 g/cm³) renders it lighter than copper substrates (density 8.9 g/cm³) while offering lower costs, making it the material of choice for LED lighting, automotive electronics, and similar sectors.

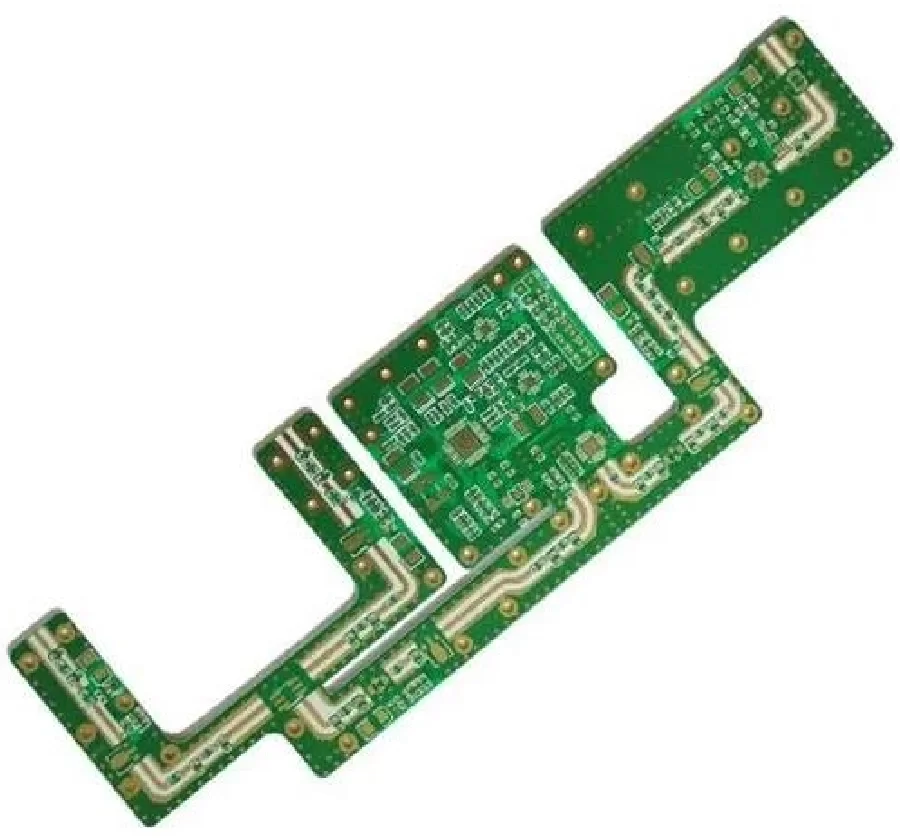

Excellent Machinability

Aluminium substrate supports conventional machining processes including drilling, punching, shearing, and cutting. Their surfaces can undergo anodising to enhance bonding strength with the insulating layer. Furthermore, aluminium substrates are compatible with Surface Mount Technology (SMT), facilitating automated production.

Environmental Sustainability

Aluminium is a recyclable material that meets environmental standards, helping to mitigate the ecological impact of electronic waste.

Corrosion Resistance of High-Conductivity Aluminium Substrates

High-conductivity aluminium substrates exhibit excellent corrosion resistance, withstanding exposure to acids, alkalis, salts, and various other chemical agents. This corrosion resistance enables their extensive application in automotive electronics, medical devices, aerospace, and other sectors.

High-conductivity aluminium substrates demonstrate broad application prospects across multiple critical domains. Particularly in electronic circuit boards, they significantly enhance heat dissipation capabilities, thereby improving the operational efficiency and service life of electronic components. In LED lighting, these substrates effectively reduce operating temperatures, boosting luminous efficiency and extending lifespan. Moreover, within automotive electronics, these substrates meet the stringent requirements of in-vehicle electronics for corrosion resistance, high-temperature tolerance, and vibration resilience.

Owing to their exceptional properties, high-conductivity aluminium substrates have become indispensable key materials in modern electronics. They play a pivotal role not only in electronic circuit boards, LED lighting, and automotive electronics but also drive continuous innovation and development across related industries by enhancing the efficiency and longevity of electronic components.